Servicio de mecanizado de precisión

Capabilities of JST Precision Machining Service

JST uses advanced mechanical equipment and precision processing technology to meet customers’ strict requirements for part size, shape and surface quality. Precision machining services usually use CNC machine tools (such as CNC milling machines, CNC lathes, CNC grinders, etc.) for processing to ensure that the parts can meet the customer’s accuracy requirements. These CNC machine tools can automatically perform complex machining operations according to pre-programmed instructions, ensuring the geometric dimensions, surface finish and shape accuracy of parts.

What is Precision Machining?

Precision machining is a subtractive manufacturing process where computer-controlled machine tools remove material from a workpiece to create parts with extremely high dimensional accuracy, complex geometries, and superior surface finishes. At JST, our precision CNC machining services utilize a suite of advanced equipment—including multi-axis CNC milling machines, CNC lathes, CNC grinders, and mill-turn centers—all operating under pre-programmed instructions. This ensures every component meets exact specifications for geometry, tolerance, and surface quality. We specialize in producing mission-critical parts for industries where failure is not an option, such as aerospace, automotive, medical devices, and precision optics.

Precision Machining Technology We Provide

CNC Milling

CNC milling is a common CNC machining technology that is automated through CNC milling machines.

It is suitable for processing plane, curved surface, holes and other shapes of parts, and can realize high precision and high efficiency.

CNC milling usually includes vertical milling, vertical and horizontal rotary table milling, gantry milling and other forms, which can meet the needs of different shapes and sizes of parts processing.

CNC Turning

CNC turning is a technology that utilizes CNC lathes for automated machining and is suitable for machining rotationally symmetrical parts.

It can realize high-precision outer and inner diameter machining, including turning, boring, countersinking, thread turning and other operations.

CNC turning is commonly used for machining shaft parts, sleeve parts, nut parts and so on.

JST can process parts samples through CNC turning technology. These samples may include different types of parts such as outer diameter processing, inner diameter processing, thread processing, etc. At the same time, we have rich processing capabilities and experience, such as shaft parts, sleeve parts, nut parts, etc.

Precision Grinding

Precision grinding is a technology that utilizes grinding tools to process workpieces with high precision.

It can realize highly accurate control of the size, shape, and surface quality of the parts, and is usually used for processing parts with high hardness and high precision requirements.

Precision grinding usually includes flat grinding, external grinding, internal grinding, surface grinding, and other forms.

JST processes part samples through precision grinding technology. These samples may include parts with flat surfaces, precise dimensions, and complex shapes. In terms of processing capabilities, we have different forms of precision grinding processing capabilities and quality control levels such as surface grinding, cylindrical grinding, internal cylindrical grinding, and surface grinding.

Turning-Milling Compound Machining

Mainly using CNC precision automatic lathes or turning-milling compound equipment, it can complete compound processing such as turning, milling, drilling, boring, tapping, and engraving at one time, mainly used for batch processing of precision hardware, shaft-type non-standard parts.

JST uses state-of-the-art CNC precision automatic lathes or mill-turning equipment, which are capable of turning, milling, drilling, boring, tapping, engraving, and other processes in a single pass to meet your processing needs for complex parts. This technology is mainly used for batch machining of precision hardware parts, non-standard parts, and so on. With our Turning-Milling Compound Machining, you can get parts with complex contours, high precisio,n and quality.

Micro Machining

Micro-machining refers to the processing of small workpieces. Micro-machining is commonly used in the fields of medical devices and electronics. Parts produced by micro-machining processes often require observation using a microscope. The diameter of the tools used for micro-machining can be as small as 0.001 inches. Micro-machining technology is a very flexible process that can produce complex shapes of micro-components.

Micromachining is one of our specialties in the medical device and electronics fields. We use micromachining technology to machine small workpieces, which often require extreme precision and meticulous finishing. Using state-of-the-art equipment and processes, we are able to machine tiny, high-precision parts with tool diameters as small as 0.001 inches. With our Micro Machining technology, you can obtain micro-sized, high-precision parts that have a wide range of applications in areas such as medical devices and electronic equipment.

All Precision Machining Materials Parameter

| No. | Material | Descripción |

|---|---|---|

| 1 | Acero 1018 | El acero General purpope 1018 es el más destacado de los aceros al carbono. Su bajo contenido en carbono lo hace dúctil y adecuado para el conformado y la soldadura. |

| 2 | Acero aleado 4140 | El cromo adicional hace que este acero sea resistente a la corrosión y a las fracturas. |

| 3 | Aluminio 2024-T3 | El aluminio 2024 se utiliza cuando se requiere una elevada relación resistencia-peso, como en engranajes, ejes y tornillería. No es magnético y se puede tratar térmicamente. |

| 4 | Aluminio 5052 | Aluminio resistente a la corrosión utilizado frecuentemente en aplicaciones de chapa metálica. |

| 5 | Aluminio 6061-T6 | El aluminio 6061 es fácil de mecanizar y ligero, perfecto para prototipos y aplicaciones militares y aeroespaciales. |

| 6 | Aluminio 6063-T5 | El aluminio 6063, que se utiliza habitualmente en exteriores como molduras arquitectónicas, barandillas y marcos de puertas, se mecaniza mejor que el 3003. No es magnético y puede tratarse térmicamente. |

| 7 | Aluminio 7075-T6 | Aleación de aluminio más dura y resistente, adecuada para piezas sometidas a grandes esfuerzos. |

| 8 | ASTM A36 | Chapa de acero laminada en caliente de uso general. Ideal para aplicaciones estructurales e industriales. |

| 9 | Latón C360 | Latón muy mecanizable. Ideal para prototipos de engranajes, racores, válvulas y tornillos. |

| 10 | Cobre 101 | Comúnmente conocida como cobre sin oxígeno, esta aleación es excelente para la conductividad eléctrica. |

| 11 | Acero inoxidable 17-4 | Aleación inoxidable de alta resistencia a la corrosión. Fácilmente tratable térmicamente. Se utiliza normalmente en equipos médicos. |

| 12 | Acero inoxidable 303 | Un material mecanizable y resistente a la corrosión. |

| 13 | Acero inoxidable 304 | Un material mecanizable y resistente a la corrosión. |

| 14 | Acero inoxidable 420 | Contiene más carbono que el inoxidable 410, lo que le confiere una mayor dureza y resistencia cuando se somete a tratamiento térmico. Ofrece una leve resistencia a la corrosión, alta resistencia al calor y mayor resistencia. |

| 15 | Titanio Grado 2 | Alta resistencia, bajo peso y alta conductividad térmica. Ideal para aplicaciones en las industrias aeroespacial y del automóvil. |

| 16 | Chapa de zinc Aleación 500 | Aleación de colada continua. Tiene buena conductividad eléctrica y es muy resistente a la corrosión. Esta aleación es fácilmente tratable para pintura, chapado y anodizado. |

| 17 | Acetal (blanco/negro) | Resina acetálica con buena resistencia a la humedad, alta resistencia al desgaste y baja fricción. |

| 18 | Acrílico (PMMA) | Plástico transparente similar al vidrio. Buenas propiedades de desgaste. Ideal para exteriores. |

| 19 | ABS negro | Plástico técnico de alta resistencia, utilizado para muchos productos comerciales. |

| 20 | Nylon 6/6 | Ofrece mayor resistencia mecánica, rigidez, buena estabilidad al calor y/o resistencia química. |

| 21 | PEEK | Al ofrecer una excelente resistencia a la tracción, el PEEK se utiliza a menudo como sustituto ligero de las piezas metálicas en aplicaciones de alta temperatura y alta tensión. El PEEK resiste los productos químicos, el desgaste y la humedad. |

| 22 | Policarbonato (PC) | Plástico transparente o coloreado, ligero y similar al vidrio, que puede mecanizarse. |

| 23 | PTFE (teflón) | Este material supera a la mayoría de los plásticos en cuanto a resistencia química y rendimiento a temperaturas extremas. Resiste a la mayoría de disolventes y es un excelente aislante eléctrico. |

Surface Finishes for Precision Machining Parts

As-Machined

Default surface from CNC; visible tool marks; roughness set by tool & parameters

Suave

Abrasive tools/media remove top layer, reducing roughness & imperfections

Granallado

Las finas perlas de vidrio crean un suave acabado mate/satinado; elimina las marcas de herramientas

Anodizado

Espesamiento electroquímico del óxido de Al natural; transparente o teñido; añade resistencia a la corrosión.

Pulido

Eliminación mecánica de material para crear una superficie lisa/brillante o similar a un espejo

Recubrimiento en polvo

Dry powder applied electrostatically & cured; durable, uniform, protective layer

Cepillado

Las bandas abrasivas/cepillos producen una textura direccional uniforme; aspecto satinado/mate

Galvanoplastia

Blast with fine glass beads/media, removes tool marks & surface imperfections; mooth, matte, satin finish

Pasivación

Tratamiento químico para acero inoxidable/metales; elimina el hierro libre, mejora la resistencia a la corrosión

Tratamiento térmico

Heating & cooling to alter hardness/strength/toughness; hardens outer layer

Electropulido

Electrochemical removal smoothes & brightens; high-gloss, reflective; improves corrosion res.

Cromado

Chemical conversion coating on Al; provides corrosion resistance & paint primer

Chorro de arena

Los medios abrasivos (arena, Al₂O₃, etc.) limpian/texturizan; más áspero que el chorreado con microesferas.

Tumbling

Acabado vibratorio con medios abrasivos; pule, desbarba, alisa piezas complejas/pequeñas

Grabado por láser

El rayo láser graba marcas permanentes (logotipos, texto, números de serie) sin modificar el acabado general.

Óxido negro

Chemical coating on steel yields black matte finish; moderate corrosion & glare reduction

Precision Machining Process

JST’s systematic precision machining approach ensures reliability, quality, and transparency from concept to delivery.

- Requirements Analysis & DFM Feedback: We begin by collaborating with you to understand your part's function, application, and critical requirements. Our engineering team performs a detailed analysis of your drawings or CAD models, providing Design for Manufacturability (DFM) feedback to optimize for cost, performance, and lead time.

- Material Selection & Process Planning: Based on the analysis, we recommend the optimal material (aluminum, stainless steel, titanium, brass, plastics) and design a detailed machining process. This includes selecting the right CNC machines, cutting tools, fixturing, and defining precise cutting parameters for each operation.

- CNC Programming & Setup: Our programmers create efficient, error-free toolpaths using advanced CAM software. Machinists then perform meticulous machine setup, including tool calibration and first-article verification, to ensure the process starts correctly.

- Multi-Technology Machining Execution: The part is manufactured using the most suitable precision machining services, which may involve: CNC Milling/Turning, Turning-Milling Compound Machining, Precision Grinding and Micro-Machining.

- Comprehensive Quality Assurance: Quality is integrated at every stage. We employ a First Article Inspection (FAI) and in-process checks using precision equipment like CMMs, optical comparators, and surface profilometers to validate all dimensions and tolerances against your specifications.

- Surface Finishing & Final Delivery: We apply specified secondary finishes (anodizing, passivation, plating, polishing) as required. Parts are carefully packaged to prevent damage and shipped according to your schedule, complete with full inspection documentation.

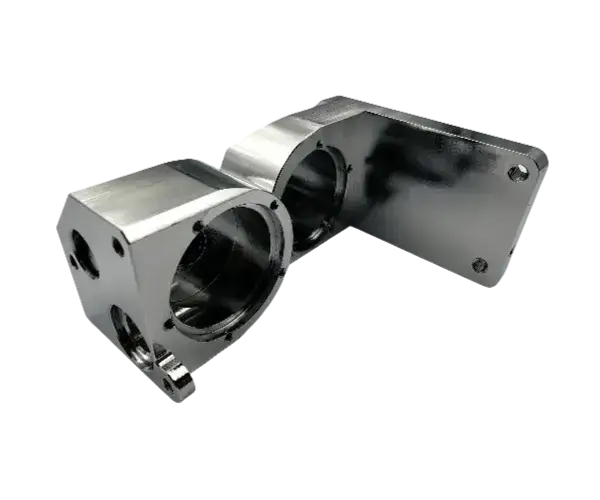

Precision Machining Parts We Can Process

JST’s comprehensive CNC precision machining service portfolio handles a vast range of parts across multiple advanced technologies.

CNC Milled & Turned Parts: We machine high-tolerance components such as complex housings, brackets, shafts, sleeves, and connectors from various materials, ensuring precise fits and functionality.

Parts from Turning-Milling Compound Machining: Ideal for complex, high-value components like precision shafts with off-center features, valve bodies, and multi-faced fittings. This technology consolidates operations, ensuring exceptional accuracy and faster turnaround for batch production of non-standard parts.

Parts from Precision Grinding: We deliver parts requiring the highest level of flatness, roundness, or surface finish. This includes gauge blocks, precision spacers, hydraulic components, and optical mounts, where tolerances are held within microns.

Micro-Machined Parts: A specialty for the medical and electronics sectors. We produce tiny, intricate components such as surgical tool tips, micro-fluidic devices, sensor housings, and miniature connectors, where extreme precision on a minuscule scale is critical.

Aplicación

The applications for precision CNC milling parts are nearly limitless. From aerospace and automotive to medical and consumer electronics, see how our expertise has been applied across industries—and imagine how we can help bring your design to life.

Fabricación industrial

Productos sanitarios

Telecommunications & Electronics

Centro de ayuda

PREGUNTAS FRECUENTES

Q: What are your standard tolerances for CNC milling services?

A: We routinely hold standard tolerances of ±0.005 inches (±0.127 mm) for machining, with even tighter tolerances achievable based on part geometry and material. We will review your drawings to confirm feasibility and recommend the most efficient approach to meet your specifications.

Q: What file formats do you accept for part quotes and manufacturing?

A: We prefer 3D solid models in STEP or IGES format, along with 2D drawings in PDF or DWG format that clearly specify critical dimensions, tolerances, material, and finish requirements. This ensures an accurate and rapid quotation process.

Q: Can you handle both prototyping and large-scale production?

A: Absolutely. Our flexible manufacturing setup and workflow are designed to efficiently manage projects of all volumes, from single prototype pieces to long-run production batches, ensuring consistent quality throughout.

Q: How do you ensure the quality of the machined parts?

A: Quality is integral at every stage. We employ a First Article Inspection (FAI) process and utilize precision measuring equipment, including CMMs, calipers, and surface testers, for in-process and final inspections. Detailed inspection reports can be provided to certify part conformity.

Q: What is your typical lead time?

A: Lead times vary based on part complexity, quantity, and current shop schedule. Generally, prototypes can be delivered in as little as 1-2 weeks, while production timelines will be quoted accordingly. We prioritize clear communication of timelines upfront and throughout your project.

Guías que puede necesitar

Servicios de fresado CNC: Guía del diseño a la entrega

La fabricación de piezas parece bastante sencilla. Enviar un dibujo, recibir los componentes acabados. Pero cualquiera que haya pasado por este proceso sabe que hay mucho más entre esos dos puntos. Entendiendo

Cómo elegir los acabados superficiales de las piezas fresadas con CNC

El mecanizado está hecho. Las piezas salen de la máquina con un aspecto decente, incluso bastante bueno. Pero la cuestión es que la superficie mecanizada no siempre es la respuesta final. A veces es

Póngase en contacto para solicitar información

Contacte con nosotros

Whatsapp:

Correo electrónico:

Tel:

+86-18915758793