· CNC Turning · CNC Milling · Turning-Milling Machining · Micro Machining

What services can jst provides

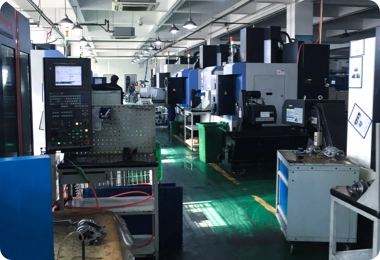

WELCOME TO OUR COMPANY - PROFESSIONAL CUSTOM CNC MACHINING SUPPLIER

KUNSHAN JST INDUSTRY CO., LTD

Kunshan JST Industry Co., Ltd is a professional CNC machining parts manufacturer, which were applied to the field of medical, aerospace & aviation, electronics, security & safety, industrial equipment and automotive. In addition, we could also manufacture the custom parts of casting & forging, metal fabrication and plastic injection parts. Our company has adhered to the principle of Innovation, Diversity and International.

WHY CHOOSE JST- CHINA CUSTOMIZED METAL PARTS MANUFACTURING

JST has been making quality CNC parts for over 10 years, and there’s a reason customers continue

to do business with us over and over again and refer to us as the “best

contract manufacturer.” Here are the many benefits of sourcing your parts from JST Industry

Quality Assurance

High customer satisfaction

Over 10 years of experience

ISO9001 certificate

Quick quotation

Competitive price

Delivery

fast

One-stop shop services

CUSTOM CNC PARTS DISPLAY

Investment Casting Pump Housing

CNC Milled Aluminum Part

CNC Turned Aluminum Parts

5/8“ 6 Nipple Claw Washer Bottom

Micro Machining Parts

Micro Machining Parts

Swiss-Type CNC Turning Lever Bottom

APPLICATIONS

Medical Devices

LATEST NEWS

Material selection happens early in the design process, but its effects ripple through everything that follows. The wrong choice shows up as parts that cost too much, wear too fast, fail unexpectedly, or simply can’t be manufactured efficiently. Getting it

Finding a machine shop isn’t hard. Finding the right one? That’s a different challenge entirely. The internet surfaces dozens of options within minutes, all claiming competitive pricing, quality workmanship, and fast turnaround. But those promises only mean something when the

Getting parts made sounds simple enough. Send a drawing, receive finished components. But anyone who’s actually gone through the process knows there’s considerably more happening between those two points. Understanding what goes on behind the scenes helps set realistic expectations

CUSTOMER FEEDBACK