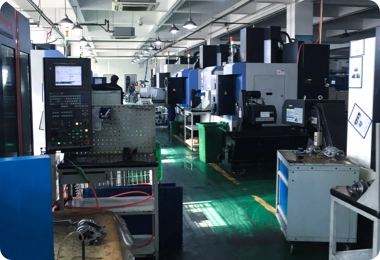

MANUFACTURING FACILITIES

JST Industry is equipped with the most advanced equipments for fast CNC machining, casting & forging, injection molding and metal fabrication, and has set up the ERP system to manage efficiently. We have hundreds of diverse equipments to meet our customers’ requirements, JST is your one-stop shop for customized metal parts and plastic parts.

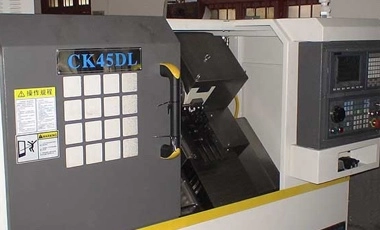

CNC Machining

· 3-axis machining center: 20 sets, DMG.

· 4-axis machining center: 20 sets, DMG.

· 5-axis machining center: 5 sets, DMG.

· CNC lathe: 20 sets, SMTCL.

· General lathe: 5 sets, SMTCL.

· Turning-Milling composite machine tool: 10 sets, DMG.

· Swiss Type lathe: 20 sets, TSUGAMI.

· Automatic lathe: 50 sets, TY.

· NC automatic lathe: 20 sets, TSUGAMI.

· Other assist equipments include Milling machine, Drilling machine, Centerless Grinding machine, External Cylindrical Grinding machine, etc.

· Inspection equipment: Vernier Caliper, Micrometer, Height Gage, Hardness Tester, Two-dimensional image measuring instrument, TESA Micro-Hite 300, Mitutoyo surface Roughness Tester, Mitutoyo CMM and Ultrasonic Cleaner.

Casting & Forging

Based on our manufacturing facilities and the local co-operating factories, we could do the sand castings, investment castings, lost wax castings, aluminum alloy die-casting, zinc alloy die-castings and forgings. We could also do the additional machining for these parts, and also the finish treatment (heat treatment, sand blasting & anodizing, polishing, powder coating, etc..) as well.

Plastic Injection

·100 tons plastic injection machine (Haitian): 4 sets.

· 150 tons plastic injection machine (Haitian): 4 sets.

· 200 tons plastic injection machine (Haitian): 5 sets.

· 250 tons plastic injection machine (Haitian): 5 sets.

· 350 tons plastic injection machine (Haitian): 5 sets.

· 500 tons plastic injection machine (Haitian): 4 sets.

· 250 tons dual-color plastic injection machine (Haitian): 2 sets.

Metal Fabrication

· 80 tons punching machine (Yangli): 2 sets.

· 120 tons punching machine (Yangli): 4 sets.

· 150 tons punching machine (Yangli): 2 sets.

· 200 tons punching machine (Yangli): 2 sets.

· 250 tons punching machine (Yangli): 4 sets.

· 300 tons punching machine (Yangli): 2 sets.

· 350 tons punching machine (Yangli): 1 sets.

· 500 tons punching machine (Yangli): 1 sets.

· CNC bending machine: 2 set

· Plate shearing machine: 2 set.

· Laser cutting machine: 4 sets.

· Laser drilling machine: 2 sets.

· Laser welding machine: 4 sets.

· TIG welding machine: 4 sets.

· Other welding machine: 10 sets.