Industria JST

Proporciona servicios de mecanizado para una amplia gama de materiales

Introducción al material de mecanizado CNC

El mecanizado CNC, o mecanizado por control numérico computerizado, es una tecnología de mecanizado automatizado que consigue una alta precisión y una gran eficacia controlando la trayectoria de la máquina herramienta mediante un programa informático. En la fabricación moderna, el mecanizado CNC Materiales se ha convertido en un medio indispensable de fabricación debido a su capacidad para satisfacer las necesidades de producción en masa de piezas complejas. Sin embargo, la calidad y la eficacia del mecanizado CNC dependen en gran medida del material seleccionado.

La selección de materiales es fundamental para el mecanizado CNC y está directamente relacionada con la funcionalidad, la durabilidad, la rentabilidad y, en última instancia, la competitividad del producto en el mercado. La selección correcta del material garantiza un proceso de mecanizado sin problemas, reduce los defectos de producción y las tasas de desechos, y también mejora el rendimiento y la vida útil del producto. Por ejemplo, las aleaciones de aluminio se utilizan habitualmente en la fabricación aeroespacial y de automoción por su ligereza y buenas propiedades mecánicas, mientras que el acero inoxidable se emplea mucho en productos químicos y dispositivos médicos por su excelente resistencia a la corrosión.

Además, las propiedades fisicoquímicas del material, como la dureza, la resistencia a la temperatura, la resistencia al desgaste y las características del tratamiento térmico, también son factores a tener en cuenta en el mecanizado CNC. Las distintas propiedades de los materiales determinan sus requisitos específicos de velocidad de corte, selección de herramientas y métodos de refrigeración durante el mecanizado. Por lo tanto, un conocimiento profundo de las propiedades de los distintos materiales es importante para optimizar los procesos de mecanizado CNC y mejorar la calidad del producto.

En JST Industry ofrecemos servicios integrales de mecanizado CNC y contamos con una amplia experiencia en el mecanizado de materiales. Animamos a nuestros clientes a comunicarse con nuestros ingenieros en la fase de diseño para proporcionarles asesoramiento experto en la selección de materiales y soluciones de mecanizado que garanticen que sus productos se fabrican de forma económica y eficiente. Mediante una cuidadosa selección de materiales y un mecanizado CNC preciso, ayudamos a que los productos de nuestros clientes destaquen en el mercado.

Mecanizado CNC de aleaciones

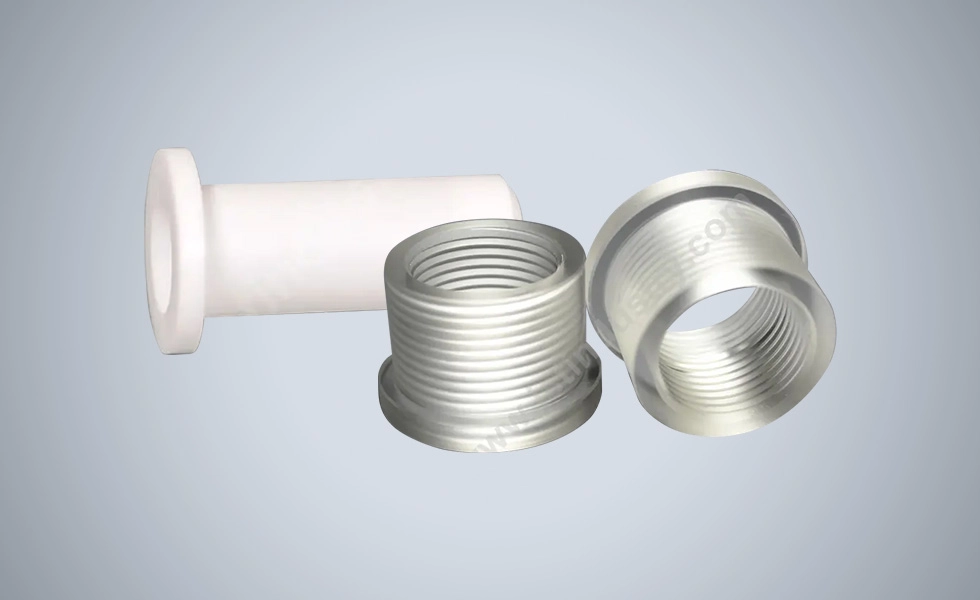

Mecanizado CNC de plásticos

Mecanizado CNC de aluminio

Mecanizado CNC de acero inoxidable

Mecanizado CNC de latón

Comparación de materiales de mecanizado CNC

En la industria del mecanizado, los distintos materiales presentan diferentes características de mecanizado y aplicaciones durante el mecanizado CNC debido a sus propiedades físicas y químicas únicas. A continuación se ofrece una comparación detallada de las diferencias y variaciones en el mecanizado CNC de aluminio, acero inoxidable, latón, aleaciones y plásticos:

Aluminio

Ligero: Las aleaciones de aluminio tienen una densidad baja, lo que las hace populares en aplicaciones donde se requiere reducir el peso, como la fabricación aeroespacial y de automóviles.

Alta conductividad térmica: Las aleaciones de aluminio tienen una excelente conductividad térmica, lo que las hace ideales para piezas que necesitan disipar el calor rápidamente, como radiadores o intercambiadores de calor.

Maquinabilidad: Las aleaciones de aluminio son fáciles de cortar y moldear, pero el mecanizado CNC genera mucho calor y requiere una refrigeración cuidadosa para evitar distorsiones.

Acero inoxidable

Resistencia a la corrosión: El acero inoxidable es muy resistente a la corrosión y la oxidación, por lo que es adecuado para aplicaciones químicas, médicas y de procesamiento de alimentos con normas sanitarias estrictas.

Fuerza: El acero inoxidable tiene un alto grado de resistencia y dureza, lo que lo hace excelente en entornos sometidos a cargas pesadas o grandes esfuerzos.

Dificultad de mecanizado: El acero inoxidable es relativamente difícil de mecanizar, por lo que requiere el uso de herramientas de corte más resistentes a la abrasión, y la refrigeración y la lubricación son más importantes durante el proceso de mecanizado.

Latón

Propiedades mecánicas: El latón tiene buenas propiedades mecánicas, como una gran resistencia y excelentes propiedades de trabajo en frío.

Estética: El latón tiene un aspecto dorado característico y suele utilizarse para piezas decorativas o aplicaciones que requieren una buena conductividad eléctrica.

Características de mecanizado: El latón tiene velocidades de corte más lentas que las aleaciones de aluminio durante el mecanizado CNC, pero sigue manteniendo una buena maquinabilidad.

Aleaciones

Ventajas específicas de la aplicación: En función de su composición y proporciones, las distintas aleaciones presentan propiedades diferentes, como alta resistencia, tenacidad o resistencia a altas temperaturas.

Versatilidad: Las aleaciones están disponibles en una amplia variedad de materiales y pueden personalizarse para satisfacer las necesidades de aplicaciones específicas.

Requisitos de mecanizado: El mecanizado CNC de aleaciones puede requerir herramientas y parámetros de mecanizado especiales para adaptarse a sus propiedades de dureza y tratamiento térmico.

Plástico

Versatilidad: Los plásticos van desde los de uso general hasta los de ingeniería, cada uno con propiedades y aplicaciones únicas.

Rentable: Los plásticos suelen ser baratos y fáciles de producir en serie para aplicaciones sensibles a los costes.

Facilidad de mecanizado: El mecanizado CNC de plásticos es relativamente sencillo y no requiere las mismas fuerzas de corte elevadas que los metales, pero hay que tener cuidado para evitar la distorsión térmica durante el mecanizado.

Comentarios sobre el servicio

Emily Thompson - Selección de materiales y rentabilidad

"Estoy muy satisfecho con los servicios de mecanizado CNC prestados por JST Industry. Su equipo de expertos ha sido de gran ayuda en la selección de materiales, permitiéndonos encontrar materiales que cumplieran los requisitos de rendimiento además de ser rentables. En particular, nos proporcionaron un análisis exhaustivo de la elección entre aleación de aluminio y acero inoxidable, lo que nos ayudó a mantener nuestro producto ligero y resistente a la corrosión, controlando al mismo tiempo los costes de forma eficaz. Durante todo el proceso, me impresionó la profesionalidad y la atención a las necesidades del cliente demostradas por JST Industry."

Ali Al-Fahad - Optimización del diseño y precisión del mecanizado

"En las primeras fases del diseño, nos preocupaba que el mecanizado CNC no pudiera cumplir nuestros estrictos requisitos de precisión del producto. Sin embargo, JST Industry disipó por completo nuestras dudas gracias a su tecnología de mecanizado de precisión y a sus cuidadosas sugerencias de optimización del diseño. Sus tolerancias de mecanizado se controlaron con tanta precisión que el tamaño y la calidad del producto final superaron con creces nuestras expectativas. Además, sus sugerencias de diseño para reducir los costes de mecanizado fueron muy prácticas, lo que desempeñó un papel clave en la optimización del diseño de nuestro producto y en la reducción de los costes totales."

Ivan Petrov - Acabado de superficies y control de calidad

"JST Industry ha hecho un trabajo excelente con el acabado superficial tras el mecanizado CNC. Nuestros productos requieren una superficie de gran calidad y ellos no sólo ofrecen una amplia gama de opciones de acabado superficial, sino que también garantizan un alto nivel de calidad y coherencia en cada proceso. Cada paso del proceso, desde el desbarbado hasta el recubrimiento final de la superficie, se somete a un estricto control de calidad, lo que da como resultado la entrega de piezas con superficies lisas y sin rebabas que cumplen plenamente nuestros estándares de calidad."

Sr. Han - Servicio de Atención al Cliente y Logística

"La experiencia general con JST Industry ha sido estupenda. Su equipo de atención al cliente es muy profesional y capaz de responder rápidamente a nuestras necesidades y preguntas. Los preparativos logísticos también estuvieron muy bien organizados y nuestros productos llegaron sanos y salvos y a tiempo, tanto en los envíos nacionales como en los internacionales. Además, proporcionan un embalaje de los productos muy cuidadoso que tiene en cuenta la fragilidad y el peso de los productos para garantizar la seguridad durante el transporte. En general, JST Industry no sólo ha destacado técnicamente, sino que también estamos muy satisfechos con su atención al cliente y la calidad de su servicio."

Preguntas frecuentes

P: Estoy diseñando un nuevo producto que requiere mecanizado CNC para crear un prototipo y el producto final. Cómo selecciono el material más adecuado para el mecanizado CNC de mi proyecto?

R: En JST Industry, sabemos que elegir el material de mecanizado CNC adecuado es fundamental para el diseño del producto. En primer lugar, debe considerar el escenario en el que se utilizará su producto, incluidas las propiedades mecánicas requeridas, la resistencia a la temperatura, la resistencia a la corrosión y la rentabilidad. Ofrecemos una amplia gama de materiales, entre los que se incluyen aleaciones de aluminio, acero inoxidable, latón, diversas aleaciones y muchos plásticos. Nuestro equipo de expertos puede ayudarle a seleccionar el material más adecuado para sus necesidades específicas y proporcionarle asesoramiento experto en optimización del diseño para garantizar un proceso de mecanizado CNC eficaz y rentable.

Q: Me gustaría saber cómo afecta la selección de diferentes materiales en el proceso de mecanizado CNC al coste final del mecanizado.

En JST Industry, somos conscientes de que la selección del material tiene un impacto significativo en los costes de mecanizado CNC. El tipo de material, la dificultad de mecanizado y la disponibilidad en el mercado influyen en su precio. Por ejemplo, el acero se utiliza ampliamente debido a su menor coste, mientras que las aleaciones de titanio y ciertas aleaciones avanzadas son más caras debido a su mayor coste de material y dificultad de mecanizado. Además, la maquinabilidad del material también afecta al coste; por ejemplo, las aleaciones de aluminio suelen ser menos caras por su facilidad de mecanizado. Nuestro sistema de presupuestos tiene en cuenta todos estos factores para garantizarle la estimación de costes más precisa.

Q: ¿Cuáles son algunas prácticas de diseño que pueden ayudarme a reducir los costes de mecanizado al diseñar piezas mecanizadas con CNC?

P: Tengo requisitos estrictos de precisión en mis productos, ¿qué tolerancias pueden alcanzarse con el mecanizado CNC y cómo afecta esto a la calidad del producto final?

R: En JST Industry, nuestros servicios de mecanizado CNC son capaces de cumplir tolerancias extremadamente altas, a menudo de ±0,01 mm, gracias a nuestros avanzados equipos de mecanizado y estrictos procesos de control de calidad. Esta capacidad de mecanizado de alta precisión garantiza la consistencia y fiabilidad de las piezas, lo que es especialmente importante para los ensamblajes que requieren un ajuste de alta precisión. Nuestro sistema de garantía de calidad incluye múltiples inspecciones y calibraciones para asegurar que cada pieza se ajusta a los planos de diseño y las tolerancias del cliente, garantizando así la calidad del producto final.