Прецизионная сталь CNC обрабатывая части для автомобильных

Introduction to Precision Steel CNC Machining Parts for Automotive

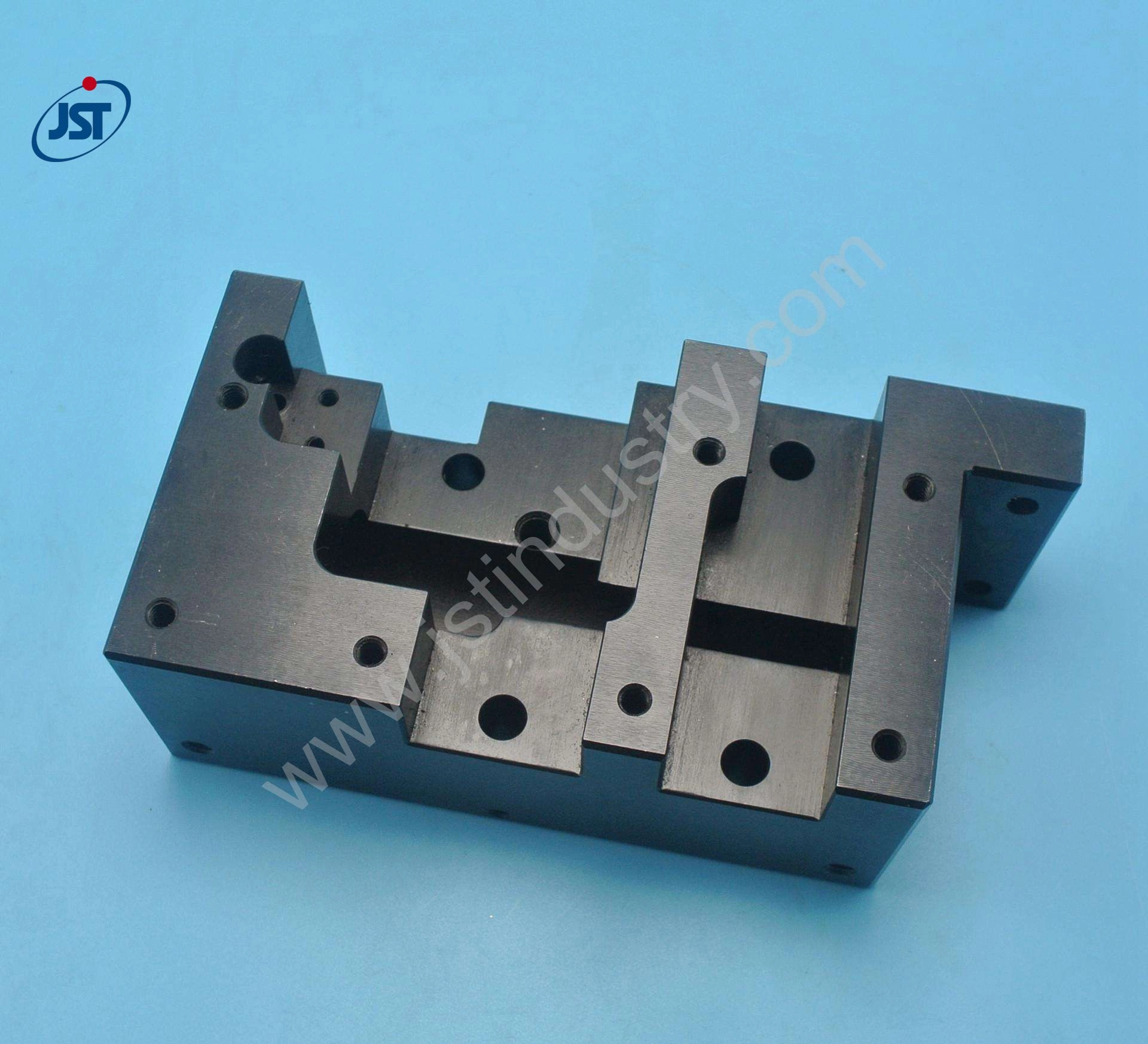

Steel machining car parts are an important aspect that is especially made for the automobile industry. The high-precision CNC machining technology guarantees that every part can meet stringent quality requirements. Apparently, the applications for these parts are greatly utilized in automobile power system, transmission system, and exterior structure parts which serve international certification and standards and surely may effectively upgrade the performance and safety of automobiles.

Features of Precision Steel CNC Machining Parts for Automotive

1. High-Precision Machining: Machining with state-of-the-art CNC machine tools to meet size and shape requirements at high precision.

2. Multiple Material Selection: Select high-quality steel, both stainless and alloy, to suit different performance requirements.

3. Custom Design: It can be designed and manufactured based on the specific requirements of the customer to achieve personalized customization.

4. Durable: High-strength steel, from which this final product can derive durability and reliability in any harsh environment.

5. Surface treatment: A wide range of options in surface treatments like zinc plating, spraying, anodizing, etc., to enhance the corrosion resistance and aesthetics of parts.

Advantages of Precision Steel CNC Machining Parts for Automotive

1. Reduce production cost: Through precision machining, the need for subsequent processing and rework is reduced, thus reducing the overall production cost.

2. Improve production efficience: Efficient production technology and flexible production capacity ensure fast delivery and effectively meet the urgent needs of customers.

3. Strict quality control: Every working procedure has a perfect quality inspection process to ensure that the finished products meet the standards before leaving the factory.

4. Strong technical support: We, as a steel machining car parts manufacturer, have an experienced team of engineers to provide professional technical support and consulting services.

5. Diversified application scenarios: Suitable for various automobile types and related products to meet the needs of customers in different industries.

Application of Precision Steel CNC Machining Parts for Automotive

These precision steel machining parts are widely used in:

1. Automobile manufacturing: Engine components, chassis components, steering systems and other important parts.

2. Motorcycle: Mechanical parts required for high-performance motorcycles.

3. Heavy machinery: used for manufacturing key parts of heavy trucks and construction machinery.

4. Аэрокосмическая промышленность: Application of some high-strength parts, such as aircraft and related equipment.

5. Logistics transportation: It is suitable for the production of spare parts for transport vehicles.

Q1: What materials can be used for your CNC machining parts?

Our CNC machining parts can be produced using various grades of steel, including carbon steel, alloy steel, stainless steel (303, 304, 316), tool steel, and more. We select the optimal material based on your automotive CNC machining parts requirements for strength, durability, and operating conditions.

Q2: What tolerance levels can you achieve for automotive CNC machining parts?

Our precision CNC machining parts typically achieve tolerances of ±0.01mm, with capabilities down to ±0.005mm for critical components. This high precision ensures a perfect fit and function for your automotive applications where exact specifications are crucial.

Q3: What is the typical lead time for custom CNC machining parts?

Standard lead time for CNC machining parts is 2-3 weeks, depending on complexity and quantity. For prototype CNC machining parts, we can offer expedited services as fast as 7-10 days. We provide flexible scheduling to accommodate your production needs.

Q4: Do you provide surface treatments for CNC machining parts?

Yes, we offer comprehensive surface treatments for CNC machining parts, including heat treatment, black oxide, zinc plating, nickel plating, chrome plating, anodizing, powder coating, and polishing. These treatments enhance the durability and appearance of automotive CNC machining parts.

Q5: Can you handle both prototyping and mass production of CNC machining parts?

Absolutely. We specialize in both prototyping and mass production of CNC machining parts. Our flexible manufacturing setup allows us to produce anything from single prototype CNC machining parts to large production runs of 100,000+ units with consistent quality.

Q6: What quality control measures do you implement for CNC machining parts?

All CNC machining parts undergo rigorous quality control, including first article inspection, in-process monitoring, and final dimensional verification using CMM and other precision measuring equipment. We provide detailed quality reports with every shipment of CNC machining parts.

“JST’s automotive CNC machining parts have significantly improved the performance of our high-end transmission systems. The precise steel components maintain exceptional dimensional stability even under extreme conditions, which has increased our product reliability and reduced warranty claims. Their engineering support during development phases has been outstanding.” —Chief Mechanical Engineer of a luxury automobile manufacturer

“We’ve been sourcing critical engine CNC machining parts from JST for over three years. Their consistent quality and tight tolerance control have helped us reduce assembly time and improve overall engine efficiency. Their ability to suggest material improvements has also contributed to extending our products’ service life.”—Purchasing Director of a commercial vehicle manufacturing company

“As a tier-one supplier to major automotive brands, quality and consistency are non-negotiable for us. JST’s CNC machining parts consistently meet our stringent specifications and arrive on schedule. Their technical team’s responsiveness when adjustments are needed has made them a trusted partner in our supply chain.”—Quality Assurance Manager of an automotive components supplier

“JST’s precision CNC machining parts have been instrumental in our electric vehicle development program. The tight tolerances and excellent surface finishes they achieve help us maintain the highest safety standards while optimizing weight. Their technical expertise in material selection has contributed significantly to our innovation efforts.”—R&D Manager of electric vehicle startup