Промышленность JST

Предоставляет услуги по обработке широкого спектра материалов

Обработка с ЧПУ Материал Введение

Обработка с ЧПУ, или обработка с компьютерным числовым программным управлением, - это автоматизированная технология обработки, которая обеспечивает высокую точность и эффективность за счет управления траекторией движения станка с помощью компьютерной программы. В современном производстве обработка материалов с ЧПУ стала незаменимым средством производства благодаря своей способности удовлетворять потребности массового производства сложных деталей. Однако качество и эффективность обработки на станках с ЧПУ во многом зависит от выбранного материала.

Выбор материала имеет решающее значение для обработки на станках с ЧПУ и напрямую связан с функциональностью, долговечностью, экономичностью и, в конечном счете, конкурентоспособностью изделия на рынке. Правильный выбор материала обеспечивает бесперебойный процесс обработки, снижает количество производственных дефектов и брака, а также повышает эксплуатационные характеристики и срок службы изделий. Например, алюминиевые сплавы широко используются в аэрокосмической и автомобильной промышленности благодаря небольшому весу и хорошим механическим свойствам, а нержавеющая сталь широко применяется в химической промышленности и производстве медицинского оборудования благодаря своей отличной коррозионной стойкости.

Кроме того, физико-химические свойства материала, такие как твердость, термостойкость, износостойкость и характеристики термообработки, также являются факторами, которые необходимо учитывать при обработке с ЧПУ. Различные свойства материалов определяют их специфические требования к скорости резания, выбору инструмента и методам охлаждения при обработке. Поэтому глубокое понимание свойств различных материалов важно для оптимизации процессов обработки с ЧПУ и повышения качества продукции.

Компания JST Industry предлагает комплексные услуги по механической обработке с ЧПУ и обладает обширным опытом в области обработки материалов. Мы рекомендуем нашим клиентам общаться с нашими инженерами на стадии проектирования, чтобы предоставить им квалифицированные советы по выбору материалов и решения по обработке, чтобы обеспечить экономичное и эффективное производство их продукции. Благодаря тщательному подбору материалов и точной обработке на станках с ЧПУ мы помогаем продукции наших клиентов выделиться на рынке.

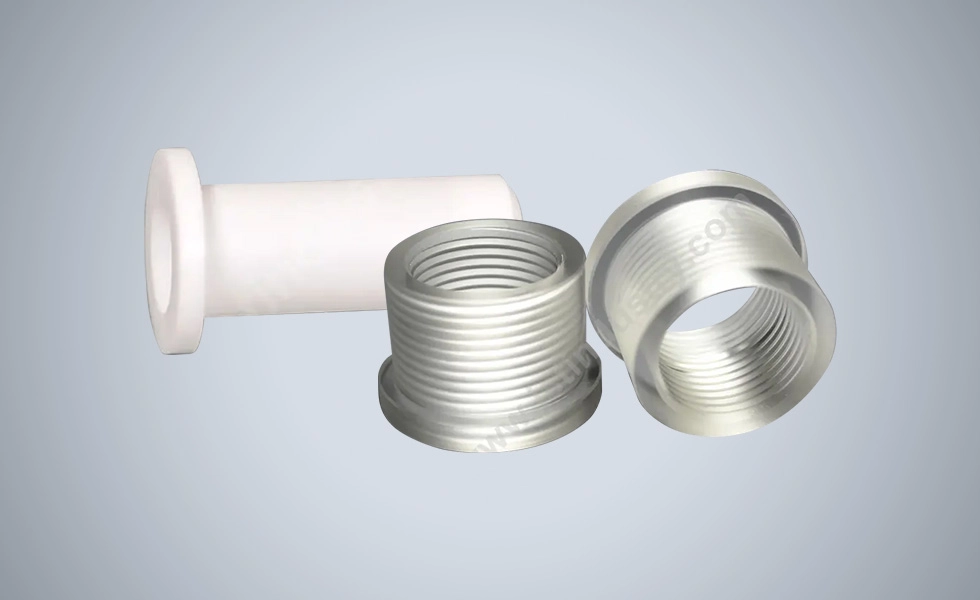

Обработка сплавов с ЧПУ

Обработка пластмасс с ЧПУ

Обработка алюминия с ЧПУ

Обработка нержавеющей стали с ЧПУ

Обработка латуни с ЧПУ

Обработка с ЧПУ Материал Сравнить

В обрабатывающей промышленности различные материалы демонстрируют различные характеристики обработки и применения при обработке с ЧПУ благодаря своим уникальным физическим и химическим свойствам. Ниже приводится подробное сравнение различий и вариаций в обработке с ЧПУ алюминия, нержавеющей стали, латуни, сплавов и пластмасс:

Алюминий

Легкий вес: Алюминиевые сплавы имеют низкую плотность, что делает их популярными в тех областях, где требуется снижение веса, например, в аэрокосмической и автомобильной промышленности.

Высокая теплопроводность: Алюминиевые сплавы обладают отличной теплопроводностью, что делает их идеальными для деталей, которым необходимо быстро отводить тепло, например, радиаторов или теплообменников.

Обрабатываемость: Алюминиевые сплавы легко режутся и формуются, но при обработке с ЧПУ выделяется много тепла и требуется тщательное охлаждение для предотвращения деформации.

Нержавеющая сталь

Устойчивость к коррозии: Нержавеющая сталь обладает высокой устойчивостью к коррозии и окислению, что позволяет использовать ее в химической, медицинской и пищевой промышленности с высокими санитарными стандартами.

Сила: Нержавеющая сталь обладает высокой степенью прочности и твердости, что делает ее превосходной в условиях, подверженных большим нагрузкам или высокому напряжению.

Сложность обработки: Нержавеющая сталь относительно трудно поддается обработке, что требует использования более износостойких режущих инструментов, а охлаждение и смазка играют более важную роль в процессе обработки.

Латунь

Механические свойства: Латунь обладает хорошими механическими свойствами, включая высокую прочность и отличные характеристики холодной обработки.

Эстетика: Латунь имеет характерный золотистый цвет и часто используется для изготовления декоративных деталей или изделий, требующих хорошей электропроводности.

Характеристики обработки: При обработке с ЧПУ латунь имеет более низкую скорость резания, чем алюминиевые сплавы, но при этом сохраняет хорошую обрабатываемость.

Сплавы (Alloy)

Преимущества с учетом специфики применения: В зависимости от состава и пропорций различные сплавы обладают разными свойствами, такими как высокая прочность, вязкость или устойчивость к высоким температурам.

Универсальность: Сплавы выпускаются в широком ассортименте и могут быть изготовлены по индивидуальному заказу для решения конкретных задач.

Требования к обработке: Для обработки сплавов с ЧПУ может потребоваться специальная оснастка и параметры обработки с учетом их твердости и свойств термообработки.

Пластик

Универсальность: Пластмассы бывают как общего назначения, так и инженерные, каждая из которых обладает уникальными свойствами и областью применения.

Эффективно с точки зрения затрат: Пластмассы, как правило, имеют низкую стоимость и просты в массовом производстве для применения в чувствительных к затратам областях.

Легкость обработки: Обработка пластмасс с ЧПУ относительно проста и не требует таких высоких усилий резания, как при обработке металлов, однако необходимо следить за тем, чтобы не допустить термических искажений во время обработки.

Отзывы о сервисе

Эмили Томпсон - Выбор материала и эффективность затрат

“Я чрезвычайно доволен услугами по механической обработке с ЧПУ, предоставляемыми компанией JST Industry. Их команда экспертов оказала нам огромную помощь в выборе материалов, позволив найти материалы, отвечающие требованиям производительности и экономичности. В частности, они провели тщательный анализ выбора между алюминиевым сплавом и нержавеющей сталью, что помогло нам сохранить легкость и коррозионную стойкость нашего продукта при эффективном контроле затрат. На протяжении всего процесса я был впечатлен профессионализмом и вниманием к потребностям клиента, которые продемонстрировала компания JST Industry”.”

Али Аль-Фахад - Оптимизация конструкции и точность обработки

“На ранних этапах проектирования мы опасались, что обработка на станках с ЧПУ не сможет удовлетворить наши строгие требования к точности продукции. Однако компания JST Industry полностью развеяла наши опасения благодаря своей технологии прецизионной обработки и тщательным предложениям по оптимизации конструкции. Допуски на обработку были настолько точно соблюдены, что размер и качество конечного продукта превзошли наши ожидания. Кроме того, их предложения по снижению стоимости обработки были очень практичными, что сыграло ключевую роль в оптимизации конструкции нашего изделия и снижении общих затрат”.”

Иван Петров - Отделка поверхностей и контроль качества

“Компания JST Industry отлично справилась с обработкой поверхности после обработки на станках с ЧПУ. Наша продукция требует высокого качества поверхности, и компания не только предлагает широкий выбор вариантов отделки поверхности, но и обеспечивает высокие стандарты и последовательность в каждом процессе. Каждый этап процесса, от снятия заусенцев до нанесения окончательного покрытия, подвергается строгому контролю качества, в результате чего мы получаем детали с гладкой, без заусенцев поверхностью, полностью соответствующие нашим стандартам качества”.”

Господин Хан - отдел обслуживания клиентов и логистики

“Общий опыт работы с JST Industry был отличным. Их команда по работе с клиентами очень профессиональна и способна быстро реагировать на наши потребности и вопросы. Логистика также была очень хорошо организована, и наши товары были доставлены в целости и сохранности и вовремя как для внутренних, так и для международных поставок. Кроме того, они обеспечивают очень тщательную упаковку продукции с учетом ее хрупкости и веса для обеспечения безопасности во время транспортировки. В целом, JST Industry не только преуспела в техническом плане, но мы также очень довольны их заботой о клиентах и качеством обслуживания”.”

Вопросы и ответы

Вопрос: Я разрабатываю новый продукт, который требует обработки на станках с ЧПУ для создания прототипа и конечного продукта. Как мне выбрать наиболее подходящий материал для обработки на станках с ЧПУ для моего проекта?

О: В компании JST Industry мы понимаем, что выбор правильного материала для обработки на станках с ЧПУ имеет решающее значение для проектирования изделия. В первую очередь необходимо учитывать сценарий, в котором будет использоваться ваше изделие, включая требуемые механические свойства, термостойкость, коррозионную стойкость и экономическую эффективность. Мы предлагаем широкий выбор материалов, включая, помимо прочего, алюминиевые сплавы, нержавеющую сталь, латунь, различные сплавы и многие пластмассы. Наша команда экспертов поможет вам выбрать наиболее подходящий материал для ваших конкретных нужд и даст рекомендации по оптимизации конструкции для обеспечения эффективного и экономичного процесса обработки с ЧПУ.

Q: Я хотел бы узнать, как выбор различных материалов в процессе обработки с ЧПУ влияет на конечную стоимость обработки?

В компании JST Industry мы понимаем, что выбор материала оказывает значительное влияние на стоимость обработки на станках с ЧПУ. Тип материала, сложность обработки и доступность на рынке - все это влияет на его цену. Например, сталь широко используется из-за своей низкой стоимости, в то время как титановые сплавы и некоторые современные сплавы являются более дорогими из-за более высокой стоимости материала и сложности обработки. Кроме того, на стоимость влияет и обрабатываемость материала, например, алюминиевые сплавы обычно дешевле из-за простоты обработки. Наша система расценок учитывает все эти факторы, чтобы обеспечить вам наиболее точную оценку стоимости.

Q: Какие конструкторские приемы помогут мне снизить затраты на обработку при проектировании деталей, обрабатываемых на станках с ЧПУ?

В: Я предъявляю жесткие требования к точности своих изделий, каких допусков можно достичь при обработке с ЧПУ и как это влияет на качество конечного продукта?

О: Благодаря современному обрабатывающему оборудованию и строгим процессам контроля качества наши услуги по механической обработке с ЧПУ в компании JST Industry могут соответствовать чрезвычайно высоким допускам, часто до ±0,01 мм. Такая высокоточная обработка обеспечивает стабильность и надежность деталей, что особенно важно для узлов, требующих высокоточной подгонки. Наша система обеспечения качества включает в себя многочисленные проверки и калибровки, чтобы гарантировать соответствие каждой детали чертежам и допускам заказчика, что гарантирует качество конечного продукта.