Quelles sont les utilisations des pièces d'usinage CNC et quels sont les matériaux couramment utilisés dans la transformation ?

1. Traitement des métaux

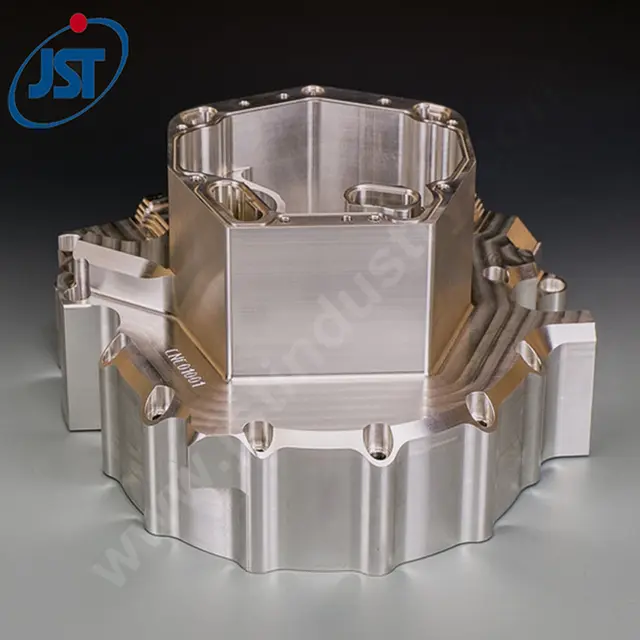

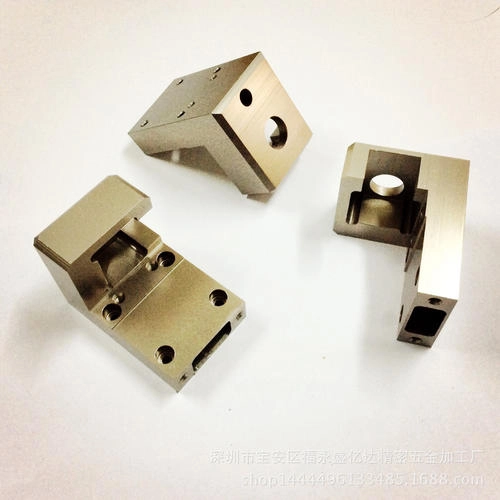

Pièces métalliques : Les centres d'usinage CNC sont largement utilisés dans le traitement de diverses pièces métalliques, notamment les alliages d'aluminium, l'acier, le cuivre, le fer, etc. Lors du traitement de ces matériaux métalliques, les machines-outils CNC peuvent démontrer leur haute précision, leur grande efficacité et leur capacité à traiter des pièces difficiles. Elles sont particulièrement adaptées au traitement de pièces de précision de tailles, de structures et de formes diverses dans des secteurs tels que l'aviation, l'aérospatiale, l'automobile et les moules.

Dans l'aérospatiale, il peut être utilisé pour traiter diverses pièces aérospatiales telles que les pales de turbines, le cuir du fuselage, les ailes, etc. Dans la construction automobile, il peut être utilisé pour traiter diverses pièces automobiles telles que les cylindres de moteur, les engrenages de transmission, etc. Dans la fabrication d'équipements électroniques, il peut traiter des métaux conducteurs et non conducteurs et divers matériaux plastiques pour la production de composants d'équipements électroniques tels que des cartes de circuits imprimés, des composants semi-conducteurs, des radiateurs, etc.

2. Transformation du plastique et du verre

L'usinage CNC convient également à la fabrication de diverses pièces en plastique et en verre. Grâce à la technologie de traitement CNC, des pièces en plastique et en verre de formes et de complexités différentes peuvent être fabriquées par traitement laser, estampage, moulage par injection, etc.

3. Traitement de pièces complexes

Les machines-outils à commande numérique peuvent traiter avec précision ces formes géométriques complexes en utilisant différents outils et stratégies de traitement. Ces pièces peuvent comporter de multiples surfaces incurvées, des biseaux, des trous et des fentes.

4. Fabrication de moules

Pièces de moule : Les formes des pièces de moule sont généralement complexes et exigent une grande précision. Les caractéristiques de haute précision et de haute efficacité des machines-outils à commande numérique répondent parfaitement à cette demande. Le traitement CNC peut également être utilisé pour fabriquer d'autres produits métalliques tels que des moules d'emboutissage et des moules d'injection.

5. Autres domaines

Transformation des aliments : La technologie de traitement des machines-outils à commande numérique permet d'obtenir une grande précision et une grande efficacité dans l'industrie alimentaire, d'améliorer la qualité des produits et l'efficacité de la production. Par exemple, elle est largement utilisée dans le traitement des conteneurs d'emballage, la fabrication de moules et l'assemblage d'équipements de transformation des aliments.

6. Production sur mesure :

Avant la production, nous fournirons des solutions appropriées basées sur les idées et les besoins du client, et nous produirons des produits personnalisés de différentes formes, tailles et complexités en fonction des différents besoins des différents clients afin de réaliser des services personnalisés.

Les matériaux couramment utilisés dans l'usinage CNC comprennent une variété de métaux, de plastiques et de matériaux composites.

Alliage d'aluminium :

Il se caractérise par sa légèreté, sa solidité et sa résistance à la corrosion. Il est généralement utilisé dans l'aérospatiale, l'automobile, les produits de consommation et d'autres domaines.

Acier inoxydable :

Ses performances sont la résistance à la corrosion et la haute résistance, et il est utilisé dans les appareils médicaux, l'aérospatiale, l'automobile, etc.

Laiton:

Le laiton présente une bonne usinabilité et une bonne résistance à la corrosion. Il est utilisé pour les décorations, les instruments de musique, les accessoires de plomberie, etc.

Le cuivre :

Il possède une excellente conductivité thermique et électrique et est utilisé pour les composants électriques et les systèmes de refroidissement.

Plastique :

Généralement utilisé pour le boîtier des produits électroniques.

Composites :

Par exemple, des pièces structurelles légères et très résistantes sont utilisées dans des applications spéciales.

Lors de la sélection des matériaux pour l'usinage CNC, des facteurs tels que l'environnement de traitement, le poids de la pièce, la rentabilité, la résistance du matériau et l'usinabilité doivent être pris en compte. Le choix des différents matériaux et technologies de traitement aura une incidence directe sur la fonction, la durabilité et la rentabilité du produit final.

Pour plus d'informations, cliquez sur Service d'usinage CNC