Industrie JST

Fournit des services d'usinage pour une large gamme de matériaux

Usinage CNC Introduction des matériaux

L'usinage CNC, ou usinage à commande numérique par ordinateur, est une technologie d'usinage automatisée qui permet d'obtenir une précision et une efficacité élevées en contrôlant la trajectoire de la machine-outil à l'aide d'un programme informatique. Dans l'industrie moderne, l'usinage CNC est devenu un moyen de fabrication indispensable en raison de sa capacité à répondre aux besoins de la production de masse de pièces complexes. Cependant, la qualité et l'efficacité de l'usinage CNC dépendent largement du matériau choisi.

La sélection des matériaux est essentielle pour l'usinage CNC et est directement liée à la fonctionnalité, à la durabilité, à la rentabilité et, en fin de compte, à la compétitivité du produit sur le marché. Une sélection correcte des matériaux garantit un processus d'usinage sans heurts, réduit les défauts de production et les taux de rebut, et améliore également les performances et la durée de vie du produit. Par exemple, les alliages d'aluminium sont couramment utilisés dans l'aérospatiale et la construction automobile en raison de leur légèreté et de leurs bonnes propriétés mécaniques, tandis que l'acier inoxydable est largement utilisé dans les produits chimiques et les dispositifs médicaux en raison de son excellente résistance à la corrosion.

En outre, les propriétés physico-chimiques du matériau, telles que la dureté, la résistance à la température, la résistance à l'usure et les caractéristiques du traitement thermique, sont également des facteurs à prendre en compte lors de l'usinage CNC. Les différentes propriétés des matériaux déterminent leurs exigences spécifiques en matière de vitesse de coupe, de sélection des outils et de méthodes de refroidissement pendant l'usinage. Par conséquent, une compréhension approfondie des propriétés des différents matériaux est importante pour optimiser les processus d'usinage CNC et améliorer la qualité des produits.

Chez JST Industry, nous offrons des services complets d'usinage CNC et possédons une vaste expérience de l'usinage des matériaux. Nous encourageons nos clients à communiquer avec nos ingénieurs dès le stade de la conception afin de leur fournir des conseils d'experts en matière de sélection des matériaux et des solutions d'usinage pour garantir que leurs produits sont fabriqués de manière économique et efficace. Grâce à une sélection minutieuse des matériaux et à un usinage CNC précis, nous aidons les produits de nos clients à se distinguer sur le marché.

Usinage CNC des alliages

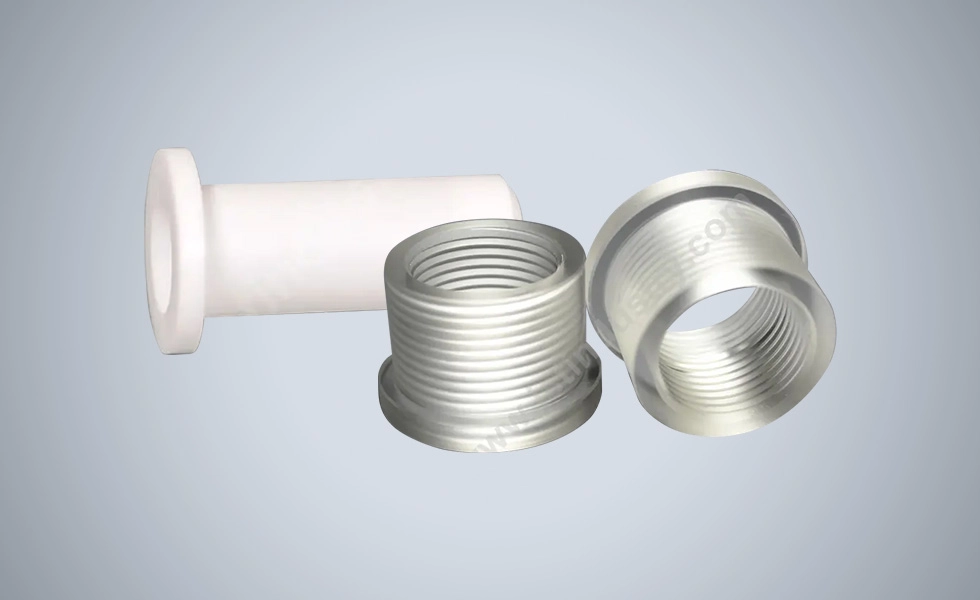

Usinage CNC des matières plastiques

Usinage CNC de l'aluminium

Usinage CNC de l'acier inoxydable

Usinage CNC du laiton

Usinage CNC Comparaison des matériaux

Dans l'industrie de l'usinage, les différents matériaux présentent des caractéristiques d'usinage et des applications différentes lors de l'usinage CNC en raison de leurs propriétés physiques et chimiques uniques. Voici une comparaison détaillée des différences et des variations dans l'usinage CNC de l'aluminium, de l'acier inoxydable, du laiton, des alliages et des plastiques :

Aluminium

Léger : Les alliages d'aluminium ont une faible densité, ce qui les rend populaires dans les applications où une réduction du poids est nécessaire, comme dans l'aérospatiale et la construction automobile.

Conductivité thermique élevée : Les alliages d'aluminium ont une excellente conductivité thermique, ce qui les rend idéaux pour les pièces qui doivent dissiper rapidement la chaleur, comme les radiateurs ou les échangeurs de chaleur.

Usinabilité : Les alliages d'aluminium sont faciles à couper et à former, mais l'usinage CNC génère beaucoup de chaleur et nécessite un refroidissement soigneux pour éviter les déformations.

Acier inoxydable

Résistance à la corrosion : L'acier inoxydable est très résistant à la corrosion et à l'oxydation, ce qui permet de l'utiliser dans des applications chimiques, médicales et alimentaires répondant à des normes sanitaires élevées.

La force : L'acier inoxydable présente un degré élevé de résistance et de dureté, ce qui en fait un excellent matériau pour les environnements soumis à de lourdes charges ou à de fortes contraintes.

Difficulté d'usinage : L'acier inoxydable est relativement difficile à usiner, ce qui nécessite l'utilisation d'outils de coupe plus résistants à l'abrasion, et le refroidissement et la lubrification sont plus importants pendant le processus d'usinage.

Laiton

Propriétés mécaniques : Le laiton possède de bonnes propriétés mécaniques, notamment une grande résistance et d'excellentes propriétés de déformation à froid.

Esthétique : Le laiton a un aspect doré distinctif et est souvent utilisé pour des pièces décoratives ou des applications nécessitant une bonne conductivité électrique.

Caractéristiques d'usinage : Le laiton a des vitesses de coupe plus lentes que les alliages d'aluminium lors de l'usinage CNC, mais conserve une bonne usinabilité.

Alliages (Alloy)

Avantages spécifiques à l'application : En fonction de leur composition et de leurs proportions, les différents alliages présentent des propriétés différentes, telles qu'une grande solidité, une grande ténacité ou une résistance aux températures élevées.

Polyvalence : Les alliages sont disponibles dans une grande variété de matériaux et peuvent être personnalisés pour répondre aux besoins d'applications spécifiques.

Exigences en matière d'usinage : L'usinage CNC des alliages peut nécessiter un outillage et des paramètres d'usinage spéciaux pour tenir compte de leur dureté et de leurs propriétés de traitement thermique.

Plastique

Polyvalence : Les plastiques vont des plastiques à usage général aux plastiques techniques, chacun ayant des propriétés et des applications uniques.

Rentable : Les plastiques sont généralement peu coûteux et faciles à produire en masse pour des applications sensibles aux coûts.

Facilité d'usinage : L'usinage CNC des matières plastiques est relativement simple et ne nécessite pas les mêmes forces de coupe élevées que les métaux, mais il faut veiller à éviter les déformations thermiques pendant l'usinage.

Retour d'information sur les services

Emily Thompson - Sélection des matériaux et rentabilité

"Je suis extrêmement satisfait des services d'usinage CNC fournis par JST Industry. Leur équipe d'experts nous a beaucoup aidés dans la sélection des matériaux, en nous permettant de trouver des matériaux qui répondent aux exigences de performance tout en étant rentables. En particulier, ils ont fourni une analyse approfondie du choix entre l'alliage d'aluminium et l'acier inoxydable, ce qui nous a permis de conserver un produit léger et résistant à la corrosion tout en contrôlant efficacement les coûts. Tout au long du processus, j'ai été impressionné par le professionnalisme et l'attention portée aux besoins du client par JST Industry".

Ali Al-Fahad - Optimisation de la conception et précision de l'usinage

"Lors des premières étapes de la conception, nous craignions que l'usinage CNC ne soit pas en mesure de répondre à nos exigences strictes en matière de précision du produit. Cependant, JST Industry a complètement dissipé nos inquiétudes grâce à sa technologie d'usinage de précision et à ses suggestions d'optimisation de la conception. Les tolérances d'usinage ont été contrôlées avec une telle précision que la taille et la qualité du produit final ont largement dépassé nos attentes. En outre, leurs suggestions de conception pour réduire les coûts d'usinage étaient très pratiques, ce qui a joué un rôle clé dans l'optimisation de la conception de notre produit et dans la réduction des coûts globaux".

Ivan Petrov - Finition des surfaces et contrôle de la qualité

"JST Industry a fait un excellent travail avec la finition de surface après l'usinage CNC. Nos produits exigent une qualité de surface fine et ils offrent non seulement une large gamme d'options de finition de surface, mais ils garantissent également des normes élevées et une cohérence dans chaque processus. Chaque étape du processus, de l'ébavurage au revêtement de surface final, est soumise à un contrôle de qualité rigoureux, ce qui permet de livrer des pièces avec des surfaces lisses et sans bavures qui répondent parfaitement à nos normes de qualité."

M. Han - Service clientèle et logistique

"L'expérience globale avec JST Industry a été excellente. L'équipe du service clientèle est très professionnelle et capable de répondre rapidement à nos besoins et à nos questions. Les dispositions logistiques ont également été très bien organisées et nos produits sont arrivés à temps et en toute sécurité, tant pour les expéditions nationales qu'internationales. En outre, l'emballage des produits est très soigné et tient compte de la fragilité et du poids des produits afin de garantir leur sécurité pendant le transport. Dans l'ensemble, JST Industry n'a pas seulement excellé sur le plan technique, mais nous sommes également très satisfaits de leur service à la clientèle et de la qualité de leur service.

FAQ

Q : Je conçois un nouveau produit qui nécessite un usinage CNC pour créer un prototype et un produit final. Comment puis-je sélectionner le matériau le plus adapté à l'usinage CNC pour mon projet ?

R : Chez JST Industry, nous savons que le choix du bon matériau d'usinage CNC est essentiel pour la conception du produit. Vous devez d'abord considérer le scénario dans lequel votre produit sera utilisé, y compris les propriétés mécaniques requises, la résistance à la température, la résistance à la corrosion et le rapport coût-efficacité. Nous proposons un large éventail de matériaux, notamment les alliages d'aluminium, l'acier inoxydable, le laiton, divers alliages et de nombreux plastiques. Notre équipe d'experts peut vous aider à sélectionner le matériau le plus approprié à vos besoins spécifiques et vous fournir des conseils d'optimisation de la conception afin de garantir un processus d'usinage CNC efficace et rentable.

Q : J'aimerais savoir comment la sélection des différents matériaux dans le processus d'usinage CNC affecte le coût final de l'usinage ?

Chez JST Industry, nous reconnaissons que la sélection des matériaux a un impact significatif sur les coûts d'usinage CNC. Le type de matériau, la difficulté de l'usinage et la disponibilité sur le marché sont autant d'éléments qui influencent son prix. Par exemple, l'acier est largement utilisé en raison de son faible coût, tandis que les alliages de titane et certains alliages avancés sont plus chers en raison du coût plus élevé du matériau et de la difficulté d'usinage. En outre, l'usinabilité du matériau influe également sur le coût, par exemple les alliages d'aluminium sont généralement moins chers en raison de leur facilité d'usinage. Notre système de devis tient compte de tous ces facteurs pour vous garantir l'estimation la plus précise possible.

Q : Quelles sont les pratiques de conception qui peuvent m'aider à réduire les coûts d'usinage lors de la conception de pièces usinées par CNC ?

Q : J'ai des exigences strictes en matière de précision pour mes produits. Quelles sont les tolérances que l'on peut obtenir avec l'usinage CNC et comment cela affecte-t-il la qualité du produit final ?

R : Chez JST Industry, nos services d'usinage CNC sont capables de respecter des tolérances extrêmement élevées, souvent de l'ordre de ±0,01 mm, grâce à notre équipement d'usinage avancé et à nos processus de contrôle de la qualité stricts. Cette capacité d'usinage de haute précision garantit la cohérence et la fiabilité des pièces, ce qui est particulièrement important pour les assemblages qui nécessitent un ajustement de haute précision. Notre système d'assurance qualité comprend de multiples inspections et étalonnages pour s'assurer que chaque pièce est conforme aux dessins et tolérances du client, garantissant ainsi la qualité du produit final.