Stainless Steel lBC Tanks

Safe Storage and Transportation for Chemical, Food, and Pharmaceutical Industries

Corrosion-Resistant | Easy to Clean | UN Certified | Long Service Life

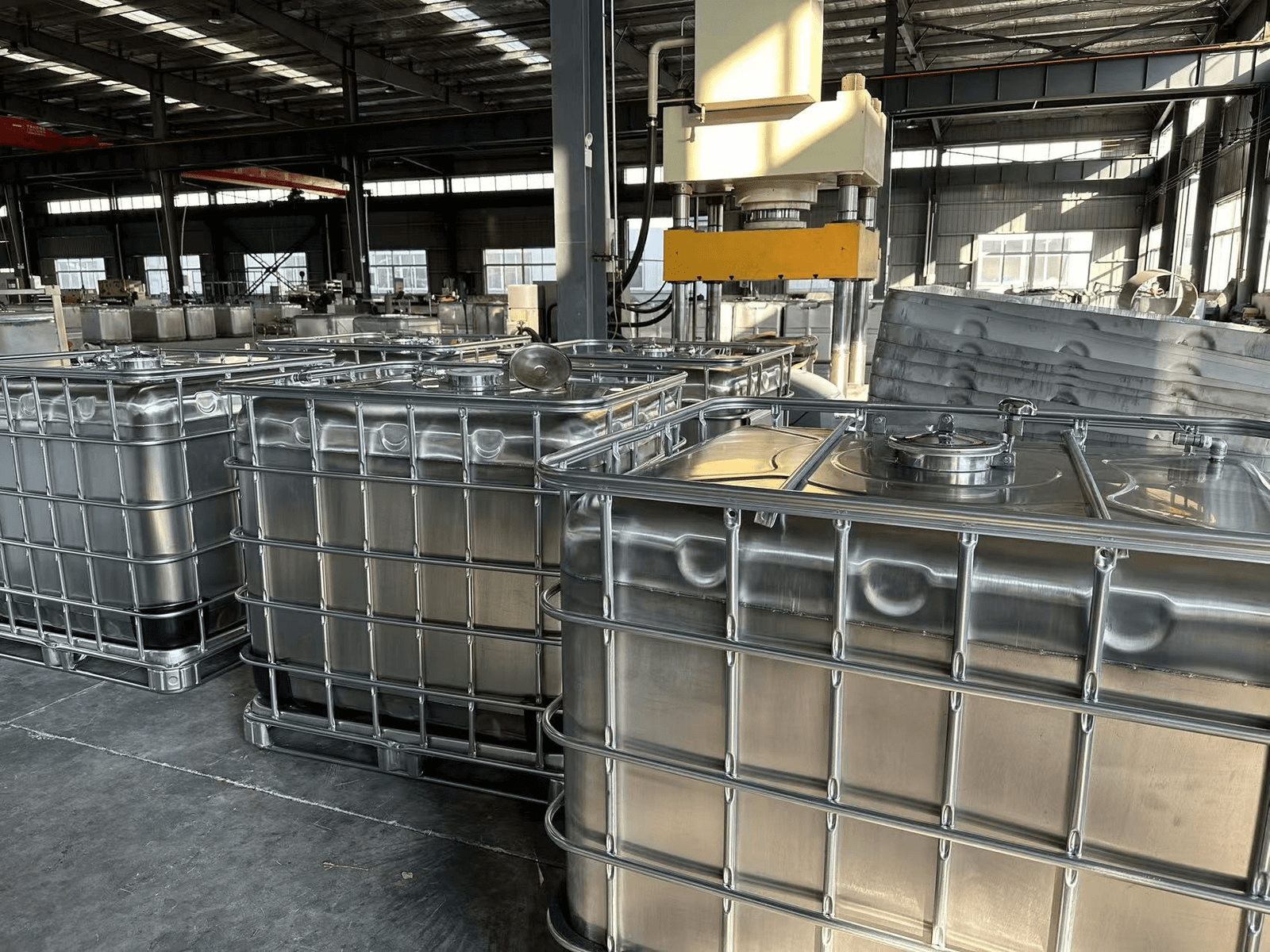

IBC Tanks (JST01)

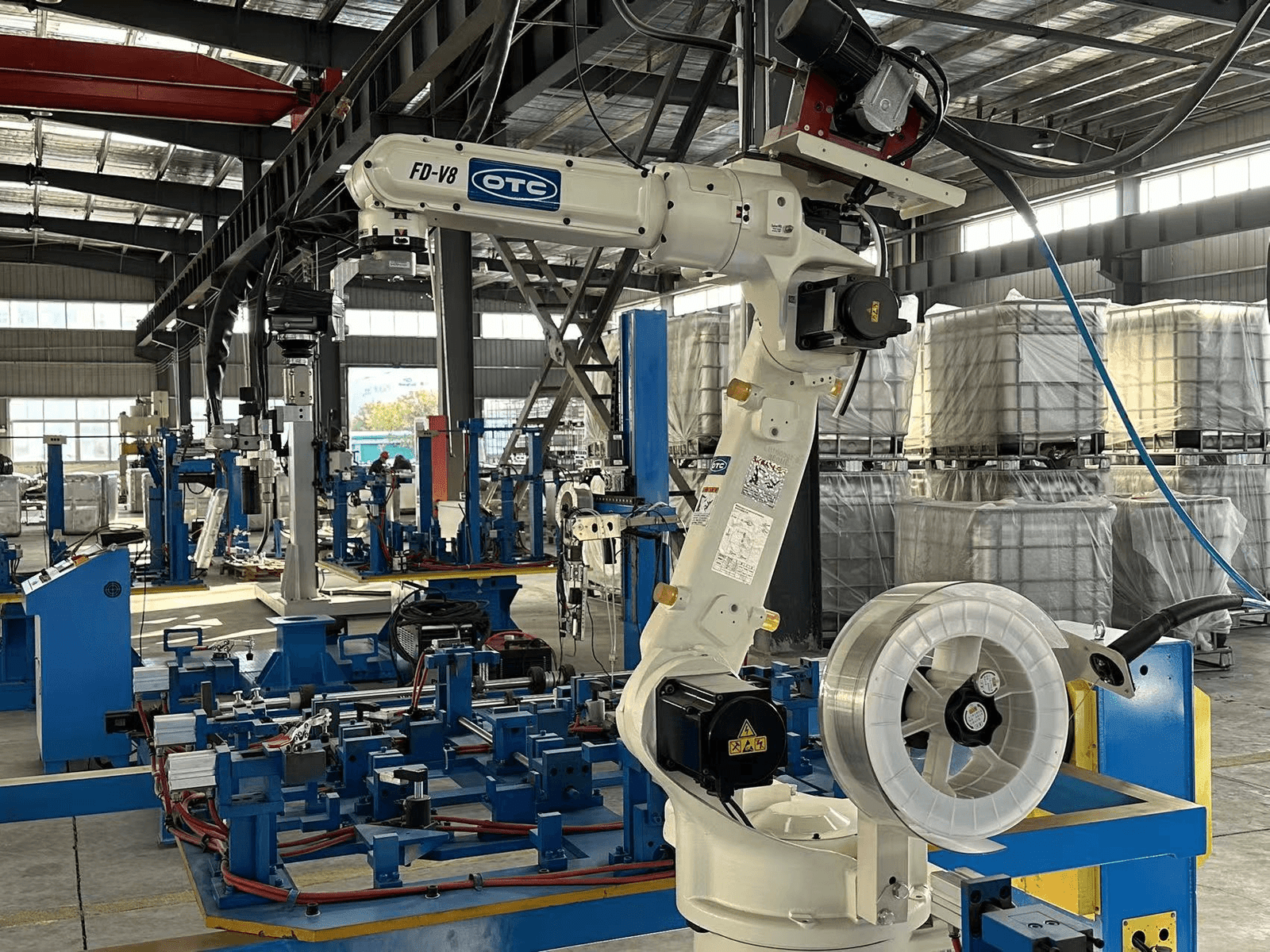

JST is one of the leading manufacturers for the stainless steel IBC tanks in China, the volume is 1000L and the material is SUS304 or SUS316. JST is equipped with the advanced welding equipment – OTC welding robot, all the processes are made in our own factory. Our manufacturing capacity is 3000 tanks per month.

Due to its advantages such as tightness, safety and corrosion resistance, our IBC tanks are widely used in the field of chemical, pharmaceutical, paint, grease, olive oil and wine. Our IBC tanks have obtained UN certification, ATEX certification(ECM) and Anti-static certification, so they can also be used to store and transport most dangerous chemical goods.

IBC Tanks (JST02)

JST is one of the leading manufacturers for the stainless steel IBC tanks in China, the volume is 1000L and the material is SUS304 or SUS316. JST is equipped with the advanced welding equipment – OTC welding robot, all the processes are made in our own factory. Our manufacturing capacity is 3000 tanks per month.

Due to its advantages such as tightness, safety and corrosion resistance, our IBC tanks are widely used in the field of chemical, pharmaceutical, paint, grease, olive oil and wine. Our IBC tanks have obtained UN certification, ATEX certification(ECM) and Anti-static certification, so they can also be used to store and transport most dangerous chemical goods.

Key Features of Stainless Steel IBC Tanks

Designed for Durability, Efficiency, and Safety

JST stainless steel IBC tanks integrate advanced engineering with user-focused design to deliver exceptional cleanliness, structural strength, and operational safety—making them the ideal choice for demanding industrial environments.

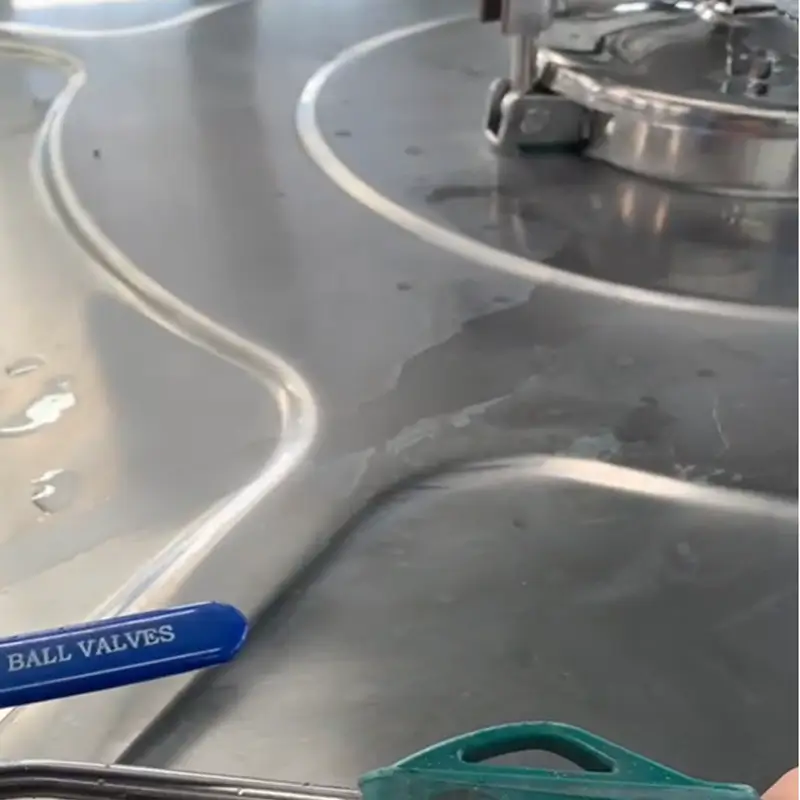

Hygienic & Easy to Clean

Smooth, polished interior (electropolished or pickled) meets strict food and pharmaceutical hygiene standards for effortless cleaning and sterilization

Robust & Long-Lasting

Built with corrosion-resistant SUS304/316 stainless steel and a heavy-duty galvanized or stainless steel cage for superior impact resistance

Safety Certified

Engineered to exceed international safety standards, rigorously tested for stackability, bottom lift, and pressure integrity (leak-proof)

Space-Saving Design

Square, stackable shape maximizes storage and shipping efficiency (fits up to 40 units in a 40HQ container)

Proven Global Reliability

Trusted by partners worldwide, with a proven track record of successful exports to Europe, the Middle East, and South America

Built to Your Specs

Customizable capacities (500L to 2000L) and materials (304 or 316L stainless steel) to meet your exact application needs

Detailed Specifications & Custom Options

Compare models and customize your stainless steel IBC tank with precise engineering details, material choices, and capacity options tailored to your requirements.

| Paramètres | JST01 | JST02 | Customized IBC Tanks |

| External Dimension (mm) | 1200X1000X1150(±5) | 1145X1145X1260(±5) | √ |

| Tare Weight(Kg) | 123 | 175 | √ |

| Nominal Capacity (L) | 1000L | 1000L | 500L/1500L/2000L |

| Maximum density (g/cm³) | 1.9 | 1.9 | 1.9 |

| Max. weight capacity (Kg) | 1900 | 1900 | 1900 |

| Matériau | Inner container: SUS304 Outer frame: galvanized steel | Inner container: SUS304 Outer frame: galvanized steel | Inner container: SUS304/SUS316 Outer frame: galvanized steel |

| Manhole diameter option | 159+/5mm, 219+/-5mm, 300+/-5mm, 400+/-5mm. | 159+/5mm, 219+/-5mm, 300+/-5mm, 400+/-5mm, 450+/-5mm | |

| Inner container | Weight(Kg):70±2; Lenghth(mm):1140±5; Width(mm):935±5; Height(mm):975±5; Thickness: 2mm. | ||

| Drain valve: | DN50 Ball valve, Inner diameter 50 (mm) | DN50 Ball valve, Inner diameter 50 (mm) |

Suitable for a Wide Range of Industries

From hazardous chemicals to food-grade liquids, JST Stainless Steel IBC Tanks deliver safe and efficient storage and handling solutions across multiple sectors.

Industrie chimique

JST stainless steel IBC tanks are ideally suited for the safe storage and transportation of a wide range of chemical substances, including solvents, raw materials, and intermediate products. Their excellent corrosion resistance and robust construction ensure reliability even when handling aggressive or sensitive chemicals.

Food & Beverage Industry

Designed to meet strict hygiene standards, our IBC tanks are widely used for storing and moving edible oils, fruit juices, wines, food additives, and other liquid food products. The smooth, non-porous interior surface allows for easy cleaning and prevents contamination, supporting compliance with food safety regulations.

Pharmaceutical Industry

In pharmaceutical applications, our tanks provide a clean and stable environment for storing raw ingredients, intermediates, and high-purity water. They are manufactured to comply with stringent quality requirements, ensuring product integrity throughout the storage and handling process.

Why Choose JST Stainless Steel IBC Tanks

JST combines manufacturing expertise, rigorous quality control, full certification support, and custom design services to provide unmatched value and reliability.

Engineering Expertise & Guaranteed Quality

With decades of metal fabrication experience, JST implements a rigorous quality control system that oversees every step—from raw material selection to finished product. Our standardized production processes and advanced welding robotics ensure consistent, reliable performance in every stainless steel IBC tank we produce.

Competitive Pricing

JST combines efficient large-scale manufacturing with direct-to-customer factory pricing. This eliminates middleman margins and allows us to offer high-value IBC solutions without compromising on quality or performance.

Full Certification & Compliance Support

Every unit comes with complete factory inspection reports. We also provide third-party testing certifications—including leak, hydrostatic, and stack load testing—and ensure full compliance with international standards such as GB/T 19161-2008.

Complimentary Custom Design Services

We offer tailored solutions based on your specific medium, operating environment, and unique requirements—such as insulation, agitation, or special fittings. Benefit from a free technical consultation and tank design proposal.

Gallery

Step inside our state-of-the-art manufacturing facility. From automated welding to rigorous quality inspections, every process is precision-controlled to ensure the reliability and performance of every stainless steel IBC tank we produce.

Workshop

Inspection

Loading

Certificates

JST Stainless Steel IBC Tanks meet the highest international standards for safety and performance. We provide full certification support, including factory test reports and third-party verification to give you complete confidence.

UN Report, Explosion-proof Test Report and Anti-static Test Report

Get In Touch For Inquiry

FAQ

Q: How do I choose between 304 and 316 stainless steel IBC Tanks?

A: 304 stainless steel is suitable for most general applications. 316 offers higher resistance to chloride corrosion, making it ideal for coastal environments or specific chemicals.

Q: What is your Minimum Order Quantity (MOQ) of Stainless Steel IBC Tanks?

A: The MOQ is typically 1 unit, though it may vary based on specifications and customization requirements.

Q: What is the lead time for delivery?

A: Standard stainless steel IBC tanks are usually shipped within 7 days after payment confirmation. Lead times for custom products will be confirmed based on order details.

Q: Do you provide Stainless Steel IBC Tanks samples?

A: Yes, please contact our sales team for our sample policy and availability.

Q: How do I install, operate, and maintain Stainless Steel IBC Tanks?

A: We provide a simple operating guide (e.g., always open the top filler cap before discharging to prevent vacuum formation) and a digital manual for installation, use, and maintenance.