What Are CNC Milling Aluminum Parts

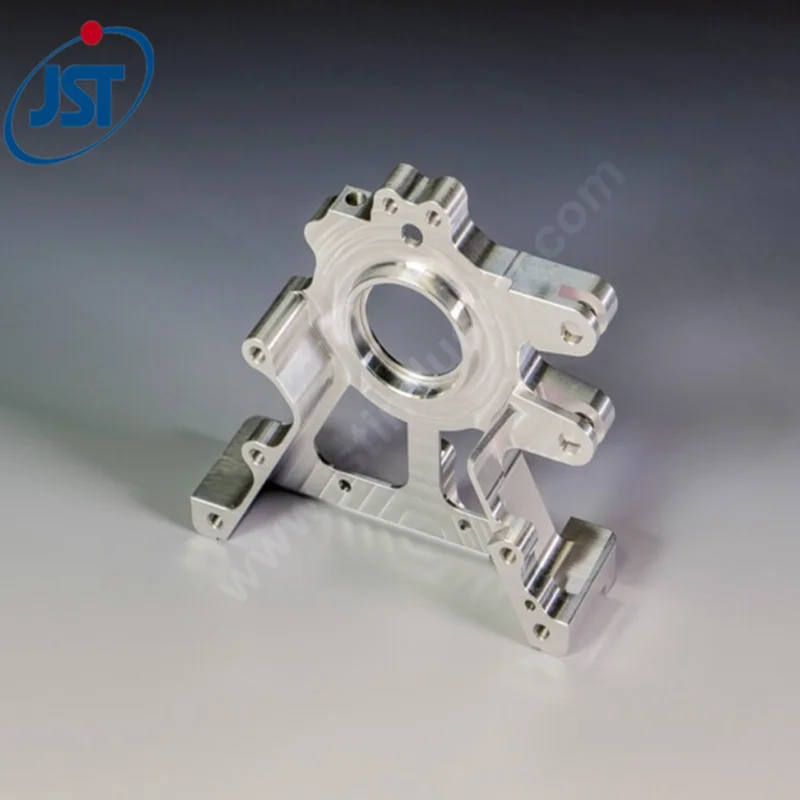

CNC Milling Aluminum Parts refer to precision components manufactured by selectively removing material from a solid block of aluminum using computer-controlled rotating cutting tools. This subtractive process is ideal for creating parts with complex geometries, intricate features, tight tolerances, and excellent surface finishes. As a versatile and fundamental manufacturing technique, CNC milling is essential for producing prototypes, functional components, and end-use parts across industries like aerospace, automotive, robotics, and consumer electronics.

Producing high-quality CNC milled aluminum parts presents distinct challenges compared to machining simpler shapes. It requires advanced multi-axis machining centers, precise toolpath programming, effective chip and heat management, and in-process monitoring to ensure dimensional accuracy and structural integrity for complex designs. Our company specializes in the custom manufacturing of Precision CNC Milling Aluminum Parts, leveraging state-of-the-art 3-axis, 4-axis, and 5-axis CNC milling centers. This advanced capability guarantees the production of components with complex contours, deep cavities, and sophisticated features in a single, efficient setup.

Aluminum alloy is the preferred material for CNC milling aluminum parts due to its outstanding combination of properties. It offers an excellent strength-to-weight ratio, good machinability, natural corrosion resistance, and high thermal and electrical conductivity. These characteristics make it the ideal choice for lightweight structural frames, enclosures, heat sinks, and high-performance components where reducing mass without sacrificing strength is critical.

Parameters of CNC Milling Aluminum Parts

| Parámetro | Detalles |

|---|---|

| Proceso de fabricación | 3-Axis, 4-Axis & 5-Axis Precision CNC Milling, High-Speed Machining |

| Materiales comunes | Aluminum 6061-T6, 7075-T6, 5052, 6082, 2024 |

| Size Range | Up to 1200mm (L) x 800mm (W) x 500mm (H) |

| Tolerancia de precisión | Standard: ±0.02 mm, High Precision: down to ±0.01 mm or better |

| Acabado superficial | As-machined: Ra 1.6 - 3.2 μm; Can achieve Ra 0.4 - 0.8 μm |

| Tratamiento posterior | Anodizing (Type II/III), Powder Coating, Sandblasting, Chemical Film, Laser Marking |

| Quality System | ISO 9001:2015 certified, IATF 16949 compliant processes for automotive. |

| Testing/Inspection | First Article Inspection (FAI), CMM, Hardness Test, Surface Roughness, Coating Thickness |

Why Choose JST's CNC Milling Aluminum Parts

Precision, Versatility, and Scalability for Demanding Applications

We provide specialized CNC milling capabilities designed to meet the rigorous demands of OEMs and innovative industries, ensuring every CNC milled aluminum part delivers on performance, complexity, and reliability:

Dedicated OEM Partnership Model

We function as an extension of your manufacturing team, offering seamless integration from design-for-manufacturability (DFM) feedback to just-in-time (JIT) delivery, ensuring your supply chain is agile and responsive.

Advanced Multi-Axis Machining Centers

Our investment in 4-axis and 5-axis CNC technology enables us to produce highly complex, monolithic CNC milling aluminum parts with intricate geometries, reducing assembly needs and improving overall part strength.

Rigorous Quality & Traceability

Every component undergoes a stringent inspection protocol. We provide complete traceability from raw material lot to finished part, giving you confidence in the consistency and reliability of every order.

Scalability from Prototype to Production

Our flexible manufacturing setup is optimized for both rapid prototyping to test form and fit, and for efficient, high-volume production runs without compromising on the precision of your CNC milled aluminum parts.

Expert Material Science Application

Our engineers provide guidance on selecting the ideal aluminum alloy (e.g., 6061 for general use, 7075 for high stress, 5052 for marine environments) to optimally balance performance, cost, and manufacturability for your application.

Aplicaciones industriales típicas

Essential Applications of Precision CNC Milling Aluminum Parts Across Industries

Our CNC milling aluminum parts serve as foundational components in advanced manufacturing, enabling innovation, efficiency, and reliability in a wide range of high-performance sectors.

| Industria | Aplicación específica | Ejemplos de piezas | Requisito clave |

|---|---|---|---|

| Aerospace & Defense | Avionics, Flight Controls, UAV Structures | Satellite brackets, antenna housings, drone chassis, actuator components | Ultra-high strength-to-weight ratio, exceptional dimensional stability, compliance with AS9100 standards. |

| Automotive & Electric Vehicles | Powertrain, Battery Systems, Chassis | Motor housings, battery pack enclosures, CNC milled aluminum parts like suspension links, ECU cases | High-volume consistency, thermal management, corrosion resistance, and IATF 16949 compliance. |

| Industrial Automation & Robotics | Robotic Arms, Machine Frames, Precision Actuators | End-effector grippers, sensor mounts, conveyor system guides, fixture plates | High stiffness, complex lightweight structures, and wear resistance for high-cycle operations. |

| Medical & Life Sciences | Diagnostic Equipment, Surgical Devices | Device housings, instrument handles, imaging system components, biopsy tool parts | Superior surface finish for sterilization, biocompatible anodizing, and adherence to cleanroom machining standards. |

| Consumer Electronics & Telecom | Device Enclosures, Heat Management, RF Components | Laptop chassis, heatsinks, waveguide components, 5G antenna parts | High aesthetic quality (via anodizing), precise thin-wall machining, and excellent EMI/RFI shielding properties. |

Nuestro proceso de personalización

Cargar y revisar

Envíe sus dibujos/archivos 3D. Reciba un análisis DFM gratuito en 24 horas.

Presupuesto y plan

Obtenga un presupuesto transparente y detallado y un calendario de producción.

Producción y control de calidad

El mecanizado CNC de precisión comienza con la inspección de la primera pieza.

Acabado e inspección

Aplicar tratamientos superficiales y realizar el control de calidad final 100%.

Entrega y asistencia

Las piezas se embalan y envían de forma segura. Documentación suministrada.

Centro de ayuda

PREGUNTAS FRECUENTES

Q: What file formats do you prefer for quoting and production?

A: We prefer 3D models in STEP or IGES format, accompanied by a 2D PDF drawing with all critical dimensions, tolerances, geometric tolerancing (GD&T), and surface finish callouts clearly defined.

Q: Can you handle both low-volume prototyping and high-volume production?

A:Absolutely. Our workflow is designed for scalability. We can produce quick-turn prototypes for design validation and then seamlessly transition to cost-optimized, high-volume production of CNC milling aluminum parts using the same validated processes.

Q: What is the typical lead time for a prototype order?

A:For standard prototype Aluminum CNC Milling Parts, lead time is typically 10-15 working days after design and PO approval. Expedited services are available upon request to meet tighter deadlines.

Q: How do you ensure the corrosion resistance of aluminum parts?

A:While aluminum naturally forms a protective oxide layer, we recommend and provide post-processing treatments like anodizing (Type III hard anodize for wear and corrosion) or chemical film conversion coating to significantly enhance corrosion resistance for harsh environments.

Q: Do you provide full manufacturing documentation?

A:Yes. As a professional OEM partner, we can supply a complete documentation package including First Article Inspection Reports (FAIR), material certifications, process control plans, and full PPAP (Level 1-5) as required by your quality system.

Guías que puede necesitar

Cómo seleccionar el material de fresado CNC adecuado para su proyecto

La selección de materiales se realiza al principio del proceso de diseño, pero sus efectos se extienden a todo lo que viene después. Una elección equivocada se traduce en piezas demasiado caras o que se desgastan demasiado rápido,

7 preguntas clave a la hora de elegir un socio de servicios de fresado CNC

Encontrar un taller mecánico no es difícil. ¿Encontrar el adecuado? Eso es un reto totalmente distinto. En Internet aparecen docenas de opciones en cuestión de minutos, todas ellas con precios competitivos, mano de obra de calidad y un servicio impecable.

Servicios de fresado CNC: Guía del diseño a la entrega

La fabricación de piezas parece bastante sencilla. Enviar un dibujo, recibir los componentes acabados. Pero cualquiera que haya pasado por este proceso sabe que hay mucho más entre esos dos puntos. Entendiendo