خدمة التصنيع الآلي الدقيق

Capabilities of JST Precision Machining Service

JST uses advanced mechanical equipment and precision processing technology to meet customers’ strict requirements for part size, shape and surface quality. Precision machining services usually use CNC machine tools (such as CNC milling machines, CNC lathes, CNC grinders, etc.) for processing to ensure that the parts can meet the customer’s accuracy requirements. These CNC machine tools can automatically perform complex machining operations according to pre-programmed instructions, ensuring the geometric dimensions, surface finish and shape accuracy of parts.

What is Precision Machining?

Precision machining is a subtractive manufacturing process where computer-controlled machine tools remove material from a workpiece to create parts with extremely high dimensional accuracy, complex geometries, and superior surface finishes. At JST, our precision CNC machining services utilize a suite of advanced equipment—including multi-axis CNC milling machines, CNC lathes, CNC grinders, and mill-turn centers—all operating under pre-programmed instructions. This ensures every component meets exact specifications for geometry, tolerance, and surface quality. We specialize in producing mission-critical parts for industries where failure is not an option, such as aerospace, automotive, medical devices, and precision optics.

Precision Machining Technology We Provide

التفريز باستخدام الحاسب الآلي الرقمي

CNC milling is a common CNC machining technology that is automated through CNC milling machines.

It is suitable for processing plane, curved surface, holes and other shapes of parts, and can realize high precision and high efficiency.

CNC milling usually includes vertical milling, vertical and horizontal rotary table milling, gantry milling and other forms, which can meet the needs of different shapes and sizes of parts processing.

الخراطة باستخدام الحاسب الآلي الرقمي

CNC turning is a technology that utilizes CNC lathes for automated machining and is suitable for machining rotationally symmetrical parts.

It can realize high-precision outer and inner diameter machining, including turning, boring, countersinking, thread turning and other operations.

CNC turning is commonly used for machining shaft parts, sleeve parts, nut parts and so on.

JST can process parts samples through CNC turning technology. These samples may include different types of parts such as outer diameter processing, inner diameter processing, thread processing, etc. At the same time, we have rich processing capabilities and experience, such as shaft parts, sleeve parts, nut parts, etc.

Precision Grinding

Precision grinding is a technology that utilizes grinding tools to process workpieces with high precision.

It can realize highly accurate control of the size, shape, and surface quality of the parts, and is usually used for processing parts with high hardness and high precision requirements.

Precision grinding usually includes flat grinding, external grinding, internal grinding, surface grinding, and other forms.

JST processes part samples through precision grinding technology. These samples may include parts with flat surfaces, precise dimensions, and complex shapes. In terms of processing capabilities, we have different forms of precision grinding processing capabilities and quality control levels such as surface grinding, cylindrical grinding, internal cylindrical grinding, and surface grinding.

Turning-Milling Compound Machining

Mainly using CNC precision automatic lathes or turning-milling compound equipment, it can complete compound processing such as turning, milling, drilling, boring, tapping, and engraving at one time, mainly used for batch processing of precision hardware, shaft-type non-standard parts.

JST uses state-of-the-art CNC precision automatic lathes or mill-turning equipment, which are capable of turning, milling, drilling, boring, tapping, engraving, and other processes in a single pass to meet your processing needs for complex parts. This technology is mainly used for batch machining of precision hardware parts, non-standard parts, and so on. With our Turning-Milling Compound Machining, you can get parts with complex contours, high precisio,n and quality.

التصنيع الآلي الدقيق

Micro-machining refers to the processing of small workpieces. Micro-machining is commonly used in the fields of medical devices and electronics. Parts produced by micro-machining processes often require observation using a microscope. The diameter of the tools used for micro-machining can be as small as 0.001 inches. Micro-machining technology is a very flexible process that can produce complex shapes of micro-components.

Micromachining is one of our specialties in the medical device and electronics fields. We use micromachining technology to machine small workpieces, which often require extreme precision and meticulous finishing. Using state-of-the-art equipment and processes, we are able to machine tiny, high-precision parts with tool diameters as small as 0.001 inches. With our Micro Machining technology, you can obtain micro-sized, high-precision parts that have a wide range of applications in areas such as medical devices and electronic equipment.

All Precision Machining Materials Parameter

| No. | المواد | Description |

|---|---|---|

| 1 | 1018 Steel | General purpope 1018 steel is the most prominent of the carbon steels. The low carbon content makes this steel ductile and suitable for forming and welding. |

| 2 | Alloy Steel 4140 | Additional chromium makes this steel corrosion and fracture resistant. |

| 3 | Aluminum 2024-T3 | 2024 aluminum is used when a high strength-to-weight ratio is required, such as for gears, shafts and fasteners. It is nonmagnetic and heat treatable. |

| 4 | Aluminum 5052 | Corrosion resistant aluminum frequently used in sheet metal applications. |

| 5 | Aluminum 6061-T6 | Aluminum 6061 is easily machined and lightweight, perfect for prototypes, military and aerospace applications. |

| 6 | Aluminum 6063-T5 | Commonly used outdoors as architectural trim, railings, and door frames, 6063 aluminum has better machinability than 3003. It is nonmagnetic and heat treatable. |

| 7 | Aluminum 7075-T6 | Harder and higher strength aluminum alloy good for high-stress parts. |

| 8 | ASTM A36 | General purpose, hot rolled steel plate. Great for structural and industrial applications. |

| 9 | Brass C360 | A highly machinable brass. Great for prototyping gears, fittings, valves and screws. |

| 10 | Copper 101 | Commonly known as Oxygen-Free Copper, this alloy is great for electrical conductivity. |

| 11 | Stainless Stee 17-4 | A high strengh, corrosion resistant stainless alloy. Easily heat treatable. Typically used in medical equipment. |

| 12 | Stainless Steel 303 | A machinable, corrosion-resistant material. |

| 13 | Stainless Steel 304 | A machinable, corrosion-resistant material. |

| 14 | Stainless Steel 420 | Contains more carbon than stainless 410 to give it increased hardness and strength when heat treated. Offers mild corrosion resistance, high heat resistance, and improved strength. |

| 15 | Titanium Grade 2 | High strength, low weight, and high thermal conductivity. Ideal for applications in the aerospace and automotive industries. |

| 16 | Zinc Sheet Alloy 500 | Continuous-cast alloy. Has good electrical conductivity and is highly resistant to corrosion. This alloy is readily treatable for painting, plating and anodizing. |

| 17 | Acetal (White/Black) | Acetal resin with good moisture resistance, high wear-resistance, and low friction. |

| 18 | Acrylic (PMMA) | A clear glass-like plastic. Good wear and tear properties. Great for outdoor use. |

| 19 | Black ABS | High strength engineering plastic, used for many commercial products. |

| 20 | Nylon 6/6 | Offers increased mechanical strength, rigidity, good stability under heat and/or chemical resistance. |

| 21 | PEEK | Offering excellent tensile strength, PEEK is often used as a lightweight substitute for metal parts in high-temperature, high-stress applications. PEEK resists chemicals, wear and moisture. |

| 22 | Polycarbonate (PC) | A clear or colored, light-weight, glass-like plastic than can be machined. |

| 23 | PTFE (Teflon) | This material surpasses most plastics when it comes to chemical resistance and performance in extreme temperatures. It resists most solvents and is an excellent electrical insulator. |

Surface Finishes for Precision Machining Parts

As-Machined

Default surface from CNC; visible tool marks; roughness set by tool & parameters

Smooth

Abrasive tools/media remove top layer, reducing roughness & imperfections

Bead Blasting

Fine glass beads/media create smooth matte/satin finish; removes tool marks

Anodizing

Electrochemical thickening of natural Al oxide; clear or dyed; adds corrosion resistance

Polishing

Mechanical removal of material to create smooth/glossy or mirror-like surface

Powder Coating

Dry powder applied electrostatically & cured; durable, uniform, protective layer

Brushing

Abrasive belts/brushes produce uniform directional texture; satin/matte look

Electroplating

Blast with fine glass beads/media, removes tool marks & surface imperfections; mooth, matte, satin finish

Passivation

Chemical treatment for stainless/metals; removes free iron, enhances corrosion resistance

Heat Treating

Heating & cooling to alter hardness/strength/toughness; hardens outer layer

Electropolishing

Electrochemical removal smoothes & brightens; high-gloss, reflective; improves corrosion res.

Chromating

Chemical conversion coating on Al; provides corrosion resistance & paint primer

Sandblasting

Abrasive media (sand, Al₂O₃, etc.) cleans/textures; rougher than bead blasting

Tumbling

Vibratory finishing with abrasive media; polishes, deburrs, smooths complex/small parts

Laser Engraving

Laser beam etches permanent markings (logos, text, serial numbers); no overall finish change

Black Oxide

Chemical coating on steel yields black matte finish; moderate corrosion & glare reduction

Precision Machining Process

JST’s systematic precision machining approach ensures reliability, quality, and transparency from concept to delivery.

- Requirements Analysis & DFM Feedback: We begin by collaborating with you to understand your part's function, application, and critical requirements. Our engineering team performs a detailed analysis of your drawings or CAD models, providing Design for Manufacturability (DFM) feedback to optimize for cost, performance, and lead time.

- Material Selection & Process Planning: Based on the analysis, we recommend the optimal material (aluminum, stainless steel, titanium, brass, plastics) and design a detailed machining process. This includes selecting the right CNC machines, cutting tools, fixturing, and defining precise cutting parameters for each operation.

- CNC Programming & Setup: Our programmers create efficient, error-free toolpaths using advanced CAM software. Machinists then perform meticulous machine setup, including tool calibration and first-article verification, to ensure the process starts correctly.

- Multi-Technology Machining Execution: The part is manufactured using the most suitable precision machining services, which may involve: CNC Milling/Turning, Turning-Milling Compound Machining, Precision Grinding and Micro-Machining.

- Comprehensive Quality Assurance: Quality is integrated at every stage. We employ a First Article Inspection (FAI) and in-process checks using precision equipment like CMMs, optical comparators, and surface profilometers to validate all dimensions and tolerances against your specifications.

- Surface Finishing & Final Delivery: We apply specified secondary finishes (anodizing, passivation, plating, polishing) as required. Parts are carefully packaged to prevent damage and shipped according to your schedule, complete with full inspection documentation.

Precision Machining Parts We Can Process

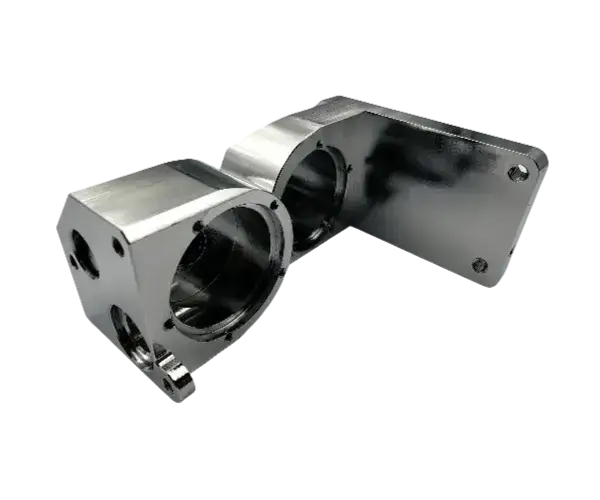

JST’s comprehensive CNC precision machining service portfolio handles a vast range of parts across multiple advanced technologies.

CNC Milled & Turned Parts: We machine high-tolerance components such as complex housings, brackets, shafts, sleeves, and connectors from various materials, ensuring precise fits and functionality.

Parts from Turning-Milling Compound Machining: Ideal for complex, high-value components like precision shafts with off-center features, valve bodies, and multi-faced fittings. This technology consolidates operations, ensuring exceptional accuracy and faster turnaround for batch production of non-standard parts.

Parts from Precision Grinding: We deliver parts requiring the highest level of flatness, roundness, or surface finish. This includes gauge blocks, precision spacers, hydraulic components, and optical mounts, where tolerances are held within microns.

Micro-Machined Parts: A specialty for the medical and electronics sectors. We produce tiny, intricate components such as surgical tool tips, micro-fluidic devices, sensor housings, and miniature connectors, where extreme precision on a minuscule scale is critical.

التطبيق

The applications for precision CNC milling parts are nearly limitless. From aerospace and automotive to medical and consumer electronics, see how our expertise has been applied across industries—and imagine how we can help bring your design to life.

الأجهزة الطبية

Help Center

الأسئلة الشائعة

Q: What are your standard tolerances for CNC milling services?

A: We routinely hold standard tolerances of ±0.005 inches (±0.127 mm) for machining, with even tighter tolerances achievable based on part geometry and material. We will review your drawings to confirm feasibility and recommend the most efficient approach to meet your specifications.

Q: What file formats do you accept for part quotes and manufacturing?

A: We prefer 3D solid models in STEP or IGES format, along with 2D drawings in PDF or DWG format that clearly specify critical dimensions, tolerances, material, and finish requirements. This ensures an accurate and rapid quotation process.

Q: Can you handle both prototyping and large-scale production?

A: Absolutely. Our flexible manufacturing setup and workflow are designed to efficiently manage projects of all volumes, from single prototype pieces to long-run production batches, ensuring consistent quality throughout.

Q: How do you ensure the quality of the machined parts?

A: Quality is integral at every stage. We employ a First Article Inspection (FAI) process and utilize precision measuring equipment, including CMMs, calipers, and surface testers, for in-process and final inspections. Detailed inspection reports can be provided to certify part conformity.

Q: What is your typical lead time?

A: Lead times vary based on part complexity, quantity, and current shop schedule. Generally, prototypes can be delivered in as little as 1-2 weeks, while production timelines will be quoted accordingly. We prioritize clear communication of timelines upfront and throughout your project.

Guides You Might Need

CNC Milling Services: Design To Delivery Guide

Getting parts made sounds simple enough. Send a drawing, receive finished components. But anyone who’s actually gone through the process knows there’s considerably more happening between those two points. Understanding

How To Choose Surface Finishes For CNC Milled Parts

The machining is done. Parts come off the machine looking decent, maybe even pretty good. But here’s the thing — that as-machined surface isn’t always the final answer. Sometimes it’s