CNC旋盤サービス

JSTは精密CNC旋盤加工サービスを提供しており、精度は±0.005mm以内に制御することができます。

What is CNC Turning?

CNC (Computer Numerical Control) turning is a advanced precision machining process where a cutting tool removes material from a rotating workpiece to create cylindrical, conical, or curved parts. Known for its high repeatability, exceptional accuracy, and efficient production speeds, it is a cornerstone of modern manufacturing.

At JST, we leverage state-of-the-art CNC lathes and a seasoned team of engineers to master this technology. Whether for simple bushings or complex rotationally symmetric components, we transform your designs into tangible CNC turning parts that meet the most stringent standards.

Main CNC Turning Materials

Which material is right for your project? The ideal choice balances strength, weight, corrosion resistance, and budget. Explore our most commonly machined materials below and leverage our expertise for your application.

アルミ素材

JST has advanced CNC turning equipment and an experienced technical team, which can accurately process various aluminum alloy materials, including 6061, 7075, etc.

We can perform customized processing according to customer requirements to ensure that the dimensional accuracy and surface quality of the parts reach the best level.

They are widely used in aerospace, automobile manufacturing and other fields.

銅材料

JSTは専門的なCNC旋盤加工能力を持ち、銅、真鍮などの様々な銅合金材料を効率的かつ正確に加工することができます。当社の設備と技術は、銅材料部品の加工品質と表面平滑性を確保することができ、電子製品、通信機器などの分野に適しています。

ステンレス素材

JSTは豊富な加工経験と先進的な設備を持っており、304、316などのステンレス材料を効率的に加工することができます。当社の技術チームは、医療機器や食品加工機器などの需要の高い分野に適したステンレス部品の加工精度と表面仕上げを保証することができます。

鉄鋼材料

JSTは先進的なCNC旋盤設備と専門的な技術チームを持っており、炭素鋼、合金鋼などの様々な鋼材を正確に加工することができます。弊社の加工能力と品質管理システムは鋼材部品の加工品質と寸法精度を確保することができ、機械設備、自動車部品などの分野に適しています。

合金材料

JSTは豊富な加工経験と先進的な設備を持っており、チタン合金、ニッケル合金などの様々な合金材料を効率的に加工することができます。当社の技術チームは、お客様のニーズに応じてカスタマイズされた加工を行い、航空宇宙やエネルギーなどのハイエンド分野に適した合金材料部品の加工品質と性能を確保することができます。

All CNC Turning Materials Parameter

| No. | 素材 | 説明 |

|---|---|---|

| 1 | 1018 Steel | General purpope 1018 steel is the most prominent of the carbon steels. The low carbon content makes this steel ductile and suitable for forming and welding. |

| 2 | Alloy Steel 4140 | Additional chromium makes this steel corrosion and fracture resistant. |

| 3 | Aluminum 2024-T3 | 2024 aluminum is used when a high strength-to-weight ratio is required, such as for gears, shafts and fasteners. It is nonmagnetic and heat treatable. |

| 4 | Aluminum 5052 | Corrosion resistant aluminum frequently used in sheet metal applications. |

| 5 | Aluminum 6061-T6 | Aluminum 6061 is easily machined and lightweight, perfect for prototypes, military and aerospace applications. |

| 6 | Aluminum 6063-T5 | Commonly used outdoors as architectural trim, railings, and door frames, 6063 aluminum has better machinability than 3003. It is nonmagnetic and heat treatable. |

| 7 | Aluminum 7075-T6 | Harder and higher strength aluminum alloy good for high-stress parts. |

| 8 | ASTM A36 | General purpose, hot rolled steel plate. Great for structural and industrial applications. |

| 9 | Brass C360 | A highly machinable brass. Great for prototyping gears, fittings, valves and screws. |

| 10 | Copper 101 | Commonly known as Oxygen-Free Copper, this alloy is great for electrical conductivity. |

| 11 | Stainless Stee 17-4 | A high strengh, corrosion resistant stainless alloy. Easily heat treatable. Typically used in medical equipment. |

| 12 | Stainless Steel 303 | A machinable, corrosion-resistant material. |

| 13 | Stainless Steel 304 | A machinable, corrosion-resistant material. |

| 14 | Stainless Steel 420 | Contains more carbon than stainless 410 to give it increased hardness and strength when heat treated. Offers mild corrosion resistance, high heat resistance, and improved strength. |

| 15 | Titanium Grade 2 | High strength, low weight, and high thermal conductivity. Ideal for applications in the aerospace and automotive industries. |

| 16 | Zinc Sheet Alloy 500 | Continuous-cast alloy. Has good electrical conductivity and is highly resistant to corrosion. This alloy is readily treatable for painting, plating and anodizing. |

| 17 | Acetal (White/Black) | Acetal resin with good moisture resistance, high wear-resistance, and low friction. |

| 18 | Acrylic (PMMA) | A clear glass-like plastic. Good wear and tear properties. Great for outdoor use. |

| 19 | Black ABS | High strength engineering plastic, used for many commercial products. |

| 20 | Nylon 6/6 | Offers increased mechanical strength, rigidity, good stability under heat and/or chemical resistance. |

| 21 | PEEK | Offering excellent tensile strength, PEEK is often used as a lightweight substitute for metal parts in high-temperature, high-stress applications. PEEK resists chemicals, wear and moisture. |

| 22 | Polycarbonate (PC) | A clear or colored, light-weight, glass-like plastic than can be machined. |

| 23 | PTFE (Teflon) | This material surpasses most plastics when it comes to chemical resistance and performance in extreme temperatures. It resists most solvents and is an excellent electrical insulator. |

Surface Finishes for CNC turning Parts

As-Machined

Default surface from CNC; visible tool marks; roughness set by tool & parameters

Smooth

Abrasive tools/media remove top layer, reducing roughness & imperfections

ビーズブラスト

Fine glass beads/media create smooth matte/satin finish; removes tool marks

陽極酸化処理

Electrochemical thickening of natural Al oxide; clear or dyed; adds corrosion resistance

Polishing

Mechanical removal of material to create smooth/glossy or mirror-like surface

パウダーコーティング

Dry powder applied electrostatically & cured; durable, uniform, protective layer

Brushing

Abrasive belts/brushes produce uniform directional texture; satin/matte look

Electroplating

Blast with fine glass beads/media, removes tool marks & surface imperfections; mooth, matte, satin finish

不動態化

Chemical treatment for stainless/metals; removes free iron, enhances corrosion resistance

熱処理

Heating & cooling to alter hardness/strength/toughness; hardens outer layer

Electropolishing

Electrochemical removal smoothes & brightens; high-gloss, reflective; improves corrosion res.

Chromating

Chemical conversion coating on Al; provides corrosion resistance & paint primer

Sandblasting

Abrasive media (sand, Al₂O₃, etc.) cleans/textures; rougher than bead blasting

Tumbling

Vibratory finishing with abrasive media; polishes, deburrs, smooths complex/small parts

Laser Engraving

Laser beam etches permanent markings (logos, text, serial numbers); no overall finish change

Black Oxide

Chemical coating on steel yields black matte finish; moderate corrosion & glare reduction

CNC旋盤の規格と公差

At JST, we understand that precision is not just a metric—it’s the foundation of performance for your CNC turning parts. Our commitment to dimensional accuracy ensures that every component we produce not only meets specifications but also delivers reliable function in your most demanding applications.

√ Standard Precision Machining: We routinely maintain exceptionally tight tolerances between ±0.01 mm to ±0.05 mm (±0.0004″ to ±0.002″), guaranteeing high dimensional accuracy and interchangeability for your projects.

√ Flexible, Customer-Centric Tolerances: Beyond our standard range, we adapt our CNC turning processes to your specific needs. We can adjust machining parameters and control tolerance ranges based on your unique application scenarios and project requirements.

√ Wide-Range Part Manufacturing: Our advanced CNC turning equipment offers high precision and stability across a vast spectrum of sizes. We expertly machine parts with diameters from a minute 0.5mm up to a substantial 500mm, and handle lengths ranging from a few millimeters to several meters.

| Turning Area | Dimension | Tolerance |

|---|---|---|

| Outer diameter | 0.5–3 mm | ±0.01 mm |

| Outer diameter | 3–6 mm | ±0.01 mm |

| Outer diameter | 6–30 mm | ±0.02 mm |

| Outer diameter | 30–120 mm | ±0.03 mm |

| Outer diameter | 120–400 mm | ±0.05 mm |

| Inner diameter | 0.5–3 mm | ±0.02 mm |

| Inner diameter | 3–6 mm | ±0.02 mm |

| Inner diameter | 6–30 mm | ±0.03 mm |

| Inner diameter | 30–120 mm | ±0.05 mm |

| Angle | 0–50 mm | ±30′ |

| Angle | 50–400 mm | ±15′ |

| Curving Radius & Bevel height | 0.5–3 mm | ±0.10 mm |

| Curving Radius & Bevel height | 3–6 mm | ±0.20 mm |

| Curving Radius & Bevel height | >6 mm | ±0.25 mm |

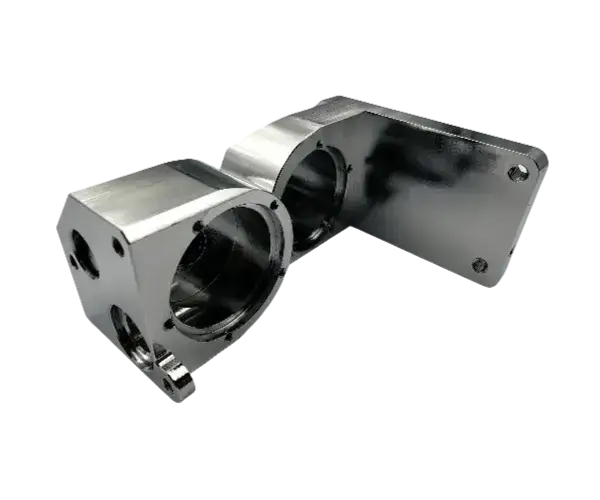

CNC Turning Parts We Can Process

長年のCNC旋盤加工サービスの経験を持つ加工会社として、JSTは、当社が製造した様々な材料のCNC旋盤加工部品とサンプルを展示することを誇りに思っています。当社の技術チームと先進的な設備により、様々な材料の加工が可能です:

- アルミニウム合金部品: 航空宇宙部品、自動車エンジン部品など、軽量で耐食性に優れた様々なアルミニウム合金部品の加工に成功しています。

- ステンレススチール部品: ステンレス素材についても豊富な実績があります。医療機器、食品加工機器などの分野で、耐食性、機械的特性に優れたステンレス部品を加工しています。

- 銅合金部品: 当社の加工能力は銅合金材料もカバーしています。電子コネクターや導電性デバイスなど、導電性や耐摩耗性に優れた様々な銅合金部品を加工してきました。

- スチール部品: 鉄鋼材料も当社の得意分野です。機械設備や自動車部品などに使用される、機械的強度と耐摩耗性に優れた炭素鋼や合金鋼の各種部品を加工しています。

- プラスチック部品: 金属材料だけでなく、POM、PTFE、PEEKなど、電子製品の筐体やエンジニアリング部品などに使用される、軽量で絶縁性の高い各種プラスチック部品の加工も可能です。

申し込み

The applications for precision CNC turned parts are nearly limitless. From aerospace and automotive to medical and consumer electronics, see how our expertise has been applied across industries—and imagine how we can help bring your design to life.

Help Center

よくあるご質問

Q: CNC旋盤加工サービスの加工技術/工程は何ですか?

A:旋盤加工:これは、CNC旋盤サービスの最も基本的な加工技術の一つです。ワークピースを回転させ、軸方向に対称性を持たせるために切削工具で切削します。ターニングは、シャフト、チューブ、面部品を含む様々な形状を作るために使用することができます。

Q: CNC旋盤加工に適した部品の種類は何ですか?

Q: What equipment is required for CNC Turning services?

A: CNC旋盤:CNC旋盤は、CNC旋盤サービスの中核機器として、ワークを回転させ、切削工具でそれらを加工することができ、高精度と効率を備えています。

自動送り機構:自動送り機構は、ワークと切削工具の相対運動を制御するために使用され、加工プロセスを自動化し、正確に制御する。

切削工具:CNC旋盤加工サービスでは、さまざまな部品加工のニーズを満たすために、旋削工具、ドリル、ボーリング工具など、さまざまな切削工具を使用する必要があります。

クランプと固定具:ワークの変形や振動を最小限に抑えながら、加工プロセスの安定性と精度を確保するために、ワークをクランプして保持するために使用される。

CNC制御システム:CNC制御システムは、加工プロセスの精度と効率を確保するために、速度、フィード、ツールパスなどのCNC旋盤の動きと加工パラメータを制御するために使用されます。

Guides You Might Need

How To Choose The Right Custom CNC Turning Parts

In modern manufacturing, custom CNC turning parts play a vital role. Whether in the aerospace, automotive industry, or medical device field, companies have an increasing demand for high-precision and custom

CNC Precision Turned Parts: Everything You Need To Know

CNC Precision Turned Parts, as an indispensable part of modern manufacturing, play a vital role. With the rapid development of science and technology and the increasing market demand for high-quality and