業界ニュース

In today’s fast-paced industries like medical, aviation, automobile, electronics, and industrial equipment, precision is paramount. JST Technology, your trusted OEM manufacturer, specializes in CNC machined parts crafted to meet the highest standards in various sectors. Precision and Expertise At JST Technology, we excel in producing CNC machined parts with precision and expertise. Our commitment to quality ensures that every component meets the stringent requirements of the medical, aviation, automobile, electronics, and industrial

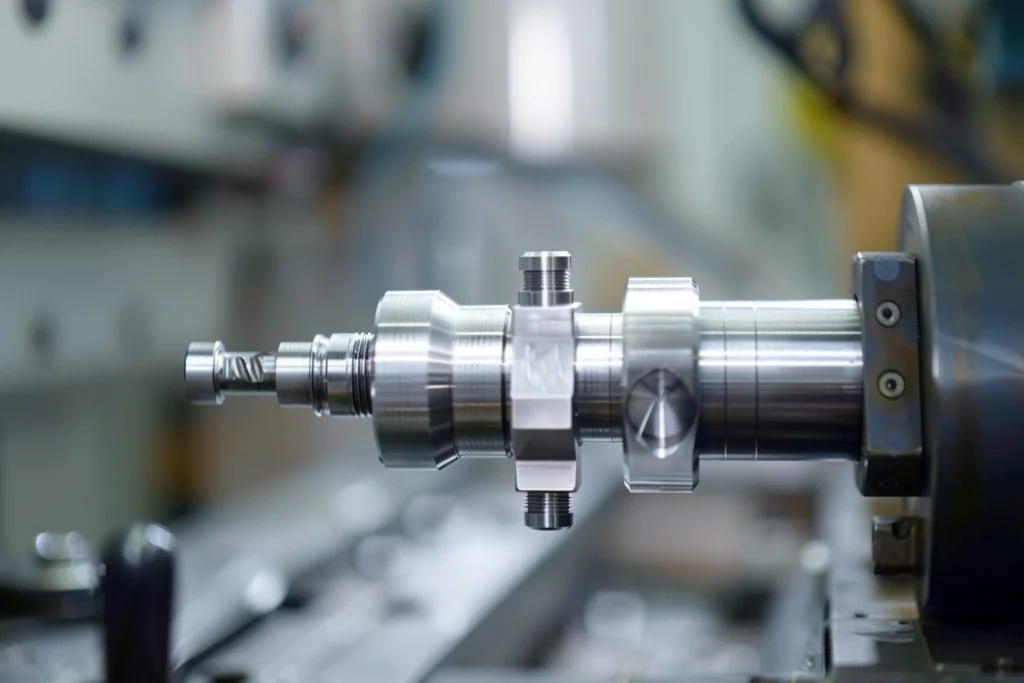

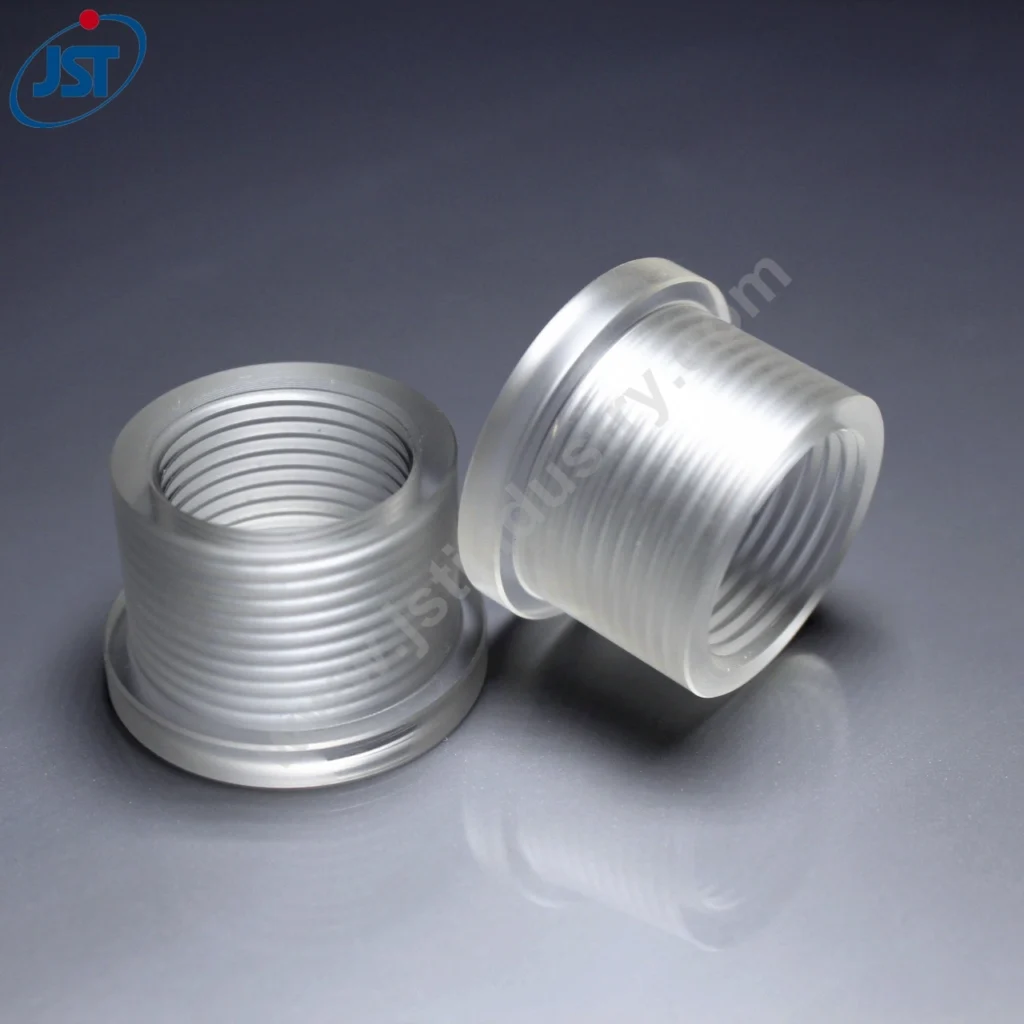

Revolutionize Your Projects Are you looking for top-tier CNC turned parts? Dive into our world of precision manufacturing. We are an OEM manufacturer specializing in CNC turning parts. Our expertise lies in transforming materials like brass, aluminum, stainless steel, free-cutting steel, and plastic into high-quality components. Materials That MatterWe understand materials. Each one has unique properties. Brass offers corrosion resistance. Aluminum is lightweight yet strong. Stainless steel is known for

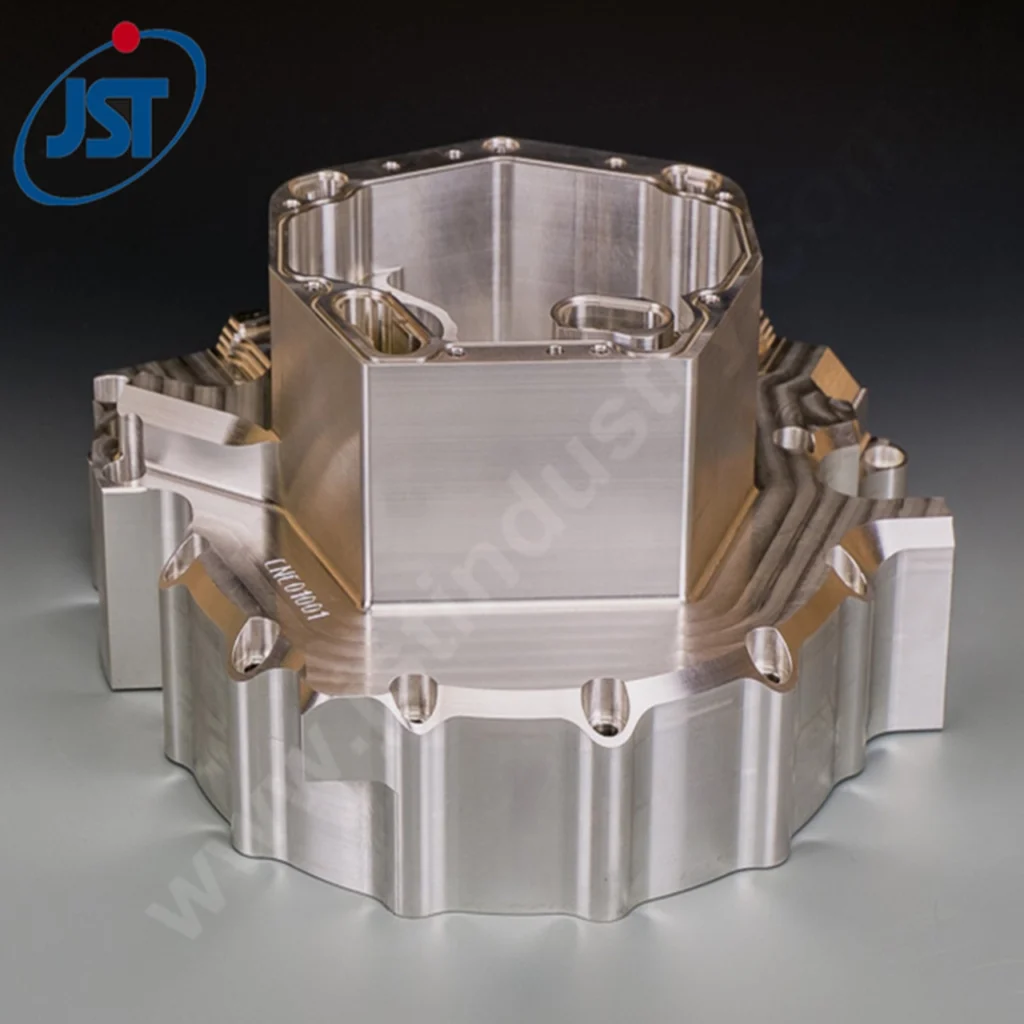

Discover the pinnacle of precision with JST, your trusted OEM manufacturer for cutting-edge 5-axis machining aluminum parts. Let’s take your projects to new heights! Why Choose JST for 5-Axis Machining? Industries We Serve: Why Partner with JST? Contact Us Today! Ready to elevate your projects with precision? Contact JST for a personalized quote, and let’s embark on a journey of precision and excellence together.

In the global landscape of manufacturing, two Asian giants, China and India, stand out as key players in the machining industry. Let’s take a closer look at the nuances that differentiate Chinese machining from its Indian counterpart. 1. Technological Prowess: China, with its massive industrial base, has invested heavily in cutting-edge technology. Precision CNC (Computer Numerical Control) machines dominate Chinese workshops, allowing for high-speed and accurate production. On the other hand,

Precision manufacturing is super important in creating tiny, accurate parts for things like medical devices and electronics. CNC micromachining is a big deal because it helps make these small parts with incredible accuracy. This article explains why CNC micromachining is so crucial in precision manufacturing and how it impacts different industries. Precision on a Small Scale: CNC micromachining uses computer-controlled machines to make really small, precise parts. Traditional methods struggle

In the realm of industrial equipment manufacturing, precision machining stands as a paramount process driving innovation and excellence. This advanced method involves the utilization of highly specialized tools and techniques to shape raw materials into intricate, accurate components that form the backbone of industrial machinery. At its core, precision machining is pivotal in ensuring the accuracy, quality, and functionality of components within industrial equipment. The process revolves around the exacting

When it comes to precision machining, quality and precision are paramount. In today’s competitive market, businesses require custom parts that meet their exact specifications, and they need a reliable supplier to make it happen. That’s where a dependable custom precision machining parts supplier comes into play. What Are Custom Precision Machining Parts? Custom precision machining parts are precisely crafted components designed to meet specific industry requirements. They are produced through

In the fast-paced world of logistics, efficiency is key. Sorting parcels accurately and swiftly is crucial for meeting customer demands. That’s where intelligent logistics sorting machines and custom CNC machining parts come into play. Let’s explore how these technologies can transform your logistics operation. The Power of Intelligent Logistics Sorting Machines Intelligent logistics sorting machines are the backbone of modern distribution centers. They use advanced technology to automate the sorting

In the fast-paced world of automotive and electronics, precision is paramount. As a leading OEM manufacturer specializing in CNC turning parts, we bring innovation and reliability to power your cars and electronics. Why Choose Our CNC Turning Parts? Driving Efficiency in the Automotive Industry: Empowering Electronics: Why Partner with Us? Elevate your products with our CNC turning parts—precision, durability, and reliability crafted for the dynamic industries of automotive and electronics.

In today’s healthcare, tiny tech breakthroughs are making big differences. Micro-machined parts in medical devices are changing the game, making treatments more precise, less invasive, and super effective. Let’s dive into the world of these small but powerful parts and see how they’re shaping better patient care. The Magic of Miniaturization Micro-machining is all about creating really small stuff, like parts that are way tinier than a grain of rice.