業界ニュース

The deformation of precision CNC turning parts in machining is a difficult problem to solve. The reason for the deformation must be analyzed first, and then countermeasures can be taken. Here is the content list: l Reduce the internal stress of precision CNC turning parts l Improve the clamping method of precision CNC turning parts Reduce the internal stress of precision CNC turning parts Natural or artificial aging, as well as vibration

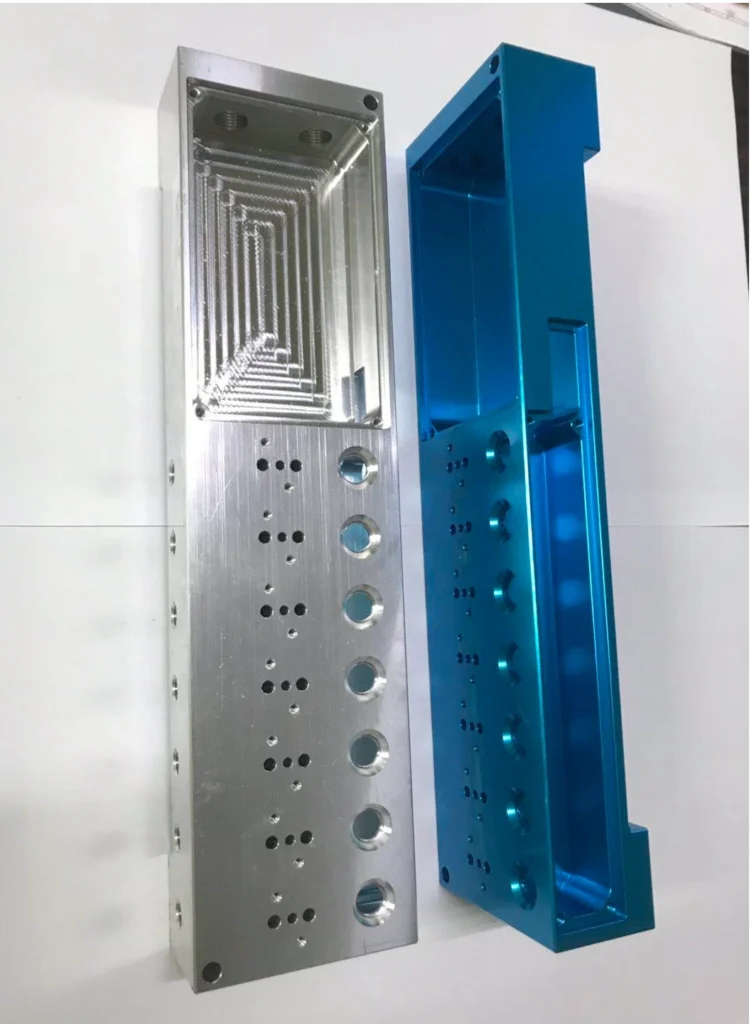

Aluminum parts made with CNC precision machining have great material properties because of the benefits of working with aluminum. These parts are valuable in many industries, including aerospace, medical equipment, and car manufacturing. This article will talk about where CNC precision machining aluminum parts are used and look at some specific examples. Advantages of aluminum CNC precision machining parts The main reason aluminum CNC precision machining parts are popular in the market is their

The history of cnc turning parts has experienced more than half a century, the cnc turning parts system has developed from the earliest analog signal circuit control into an extremely complex integrated processing system, programming methods have also developed into intelligent, powerful CAD/CAM integrated system manually. The advantages of the precision cnc turning parts the influence factors of machining precision cnc turning parts tur and its countermeasures How to improve the accuracy of precision cnc turning parts The advantages of the precision cnc turning parts

The history of precision cnc turning parts has experienced more than half a century, the cnc turning parts system has developed from the earliest analog signal circuit control into an extremely complex integrated processing system, programming methods have also developed into intelligent, powerful CAD/CAM integrated system manually. As far as our country is concerned, the development of precision cnc turning parts is relatively slow, for most of the domestic workshop. The equipment is relatively backward, and the

The processing of precision CNC turning parts is to change the shape and size of the precision CNC turning parts on the lathe, using the rotational movement of the precision CNC turning parts and the linear or curved motion of the tool. At the same time, the precision CNC turning parts are used to transform the CNC turning parts. Produced into precision CNC turning parts, and processed the precision CNC turning parts

As part of the manufacturing industry, precision CNC turning technology is a mainstream drive in today’s industrial world. Not only is it a processing technology, but it also represents innovation and efficiency. This article expounds the basic concepts, working principles and significance of precision CNC turning technology in modern manufacturing and looks at its flexibility and advantages in customized services. Basic Concepts Precision CNC turning technology is a key process

With precision CNC turning, we use computer-controlled machines to make parts very accurately. This method is better than the old ways because it makes the parts more exact and uniform. In this process, we put the workpiece on a spindle that turns. A cutting tool goes in different directions to take off the right amount of material. This gives the part the exact shape it needs. Precision CNC Turning: Precision

Revolutionizing production: An introduction to CNC milling parts Today, CNC milling parts is key to the aerospace industry, making accurate parts for planes and rockets. It also makes important parts for the electronics we use daily, such as smartphones and computers.This article tells about the process of CNC milling parts from production to their application in modern production, as well as the role of CNC milling services. It has brought great changes

Stamping technology is becoming increasingly important in the manufacturing industry. With its high efficiency and low cost, stamping parts have become an important part of industrial manufacturing. Stamping parts are used in automotive parts, electronics, household appliances and many other areas. With the increase in demand, stamping technology is being improved to produce better quality parts to meet the high demand in the market. Application of Stamping Parts in Manufacturing Stamping technology

Technical expertise and skills assessment When selecting a CNC machining service provider, it is important to assess their experience with specific materials and industries. This assessment helps ensure that the supplier has the necessary expertise to meet the specific needs of your project. For example, a supplier with aerospace experience may not be the best choice for medical device manufacturing, where standards and material requirements vary. Key factors to consider