CNC Requirements

Application Needs

Start by knowing what your CNC precision machining parts will do. Think about how it will be used. Will it need to handle a lot of force? Does it need to stop rust? Write down the most important things your part must do. Some parts need to work in hot places. Others need to stay strong against rust. If you work in aerospace or medical fields, you might need special CNC machining material. Always pick material that fits your work area.

Tip: Make a list of what your part needs before picking any cnc machining material.

Technical Drawings

Technical drawings help you share your ideas with the team. You should make drawings that are easy to read. These drawings show the size and shape of your part. They also show any special features. Good drawings help the CNC team know what you want. They also help stop mistakes from happening. If you are not sure how to make drawings, ask your supplier for help.

- Add every measurement.

- Point out special features.

- Show where you need tight tolerances.

Tolérances

Tolerances tell the team how close the part must match the drawing. Tight tolerances mean the part must be very exact. Only ask for tight tolerances if you really need them. Tight tolerances can make the job harder and cost more. Think about which parts need to be very precise. Moving parts or sealing areas often need tight tolerances. Pick the right CNC machining material to help with these needs.

| Tolerance Level | Use Case Example | Material Consideration |

|---|---|---|

| Standard | Brackets, covers | General CNC machining material |

| Tight | Shafts, gears | High strength, corrosion resistance |

Choosing CNC Precision Machining Parts

Sélection des matériaux

When you pick Pièces d'usinage de précision CNC, think about the material. The material you choose changes how your part works and how long it lasts. It also changes the price. Look at things like strength, corrosion resistance, weight, and how the material handles heat. These things help you know if the part will work well for you.

- Pick a high-strength alloy if you need strong parts.

- If your part touches water or chemicals, it needs to resist rust.

- Light materials are good for cars or planes.

- Materials that handle heat well are best for hot places.

Tip: Picking the right material can save money and stop your part from breaking.

Always pick the best material for your CNC precision machining parts. Some jobs, like in medical or aerospace, need special CNC machining material. You must check if the CNC machining material fits your industry rules. Ask your supplier if they know about different CNC machining materials. Good material choice makes sure your Pièces d'usinage CNC work for you.

| Material Type | Strength | Résistance à la corrosion | Weight | Thermal Properties |

|---|---|---|---|---|

| Aluminium | Medium | Good | Light | Good |

| Acier inoxydable | High | Excellent | Heavy | Moderate |

| Titane | High | Excellent | Light | Excellent |

| Plastiques | Low | Varies | Very Light | Poor/Good |

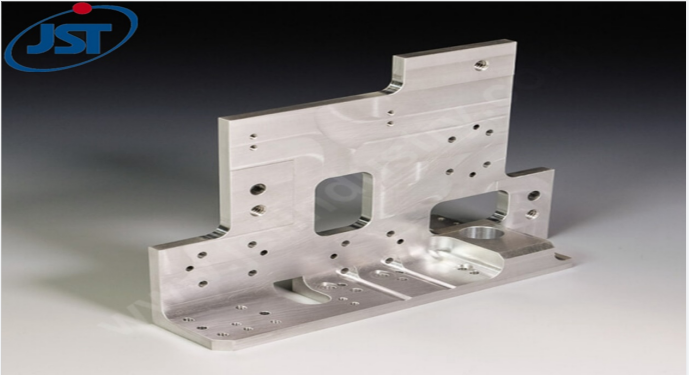

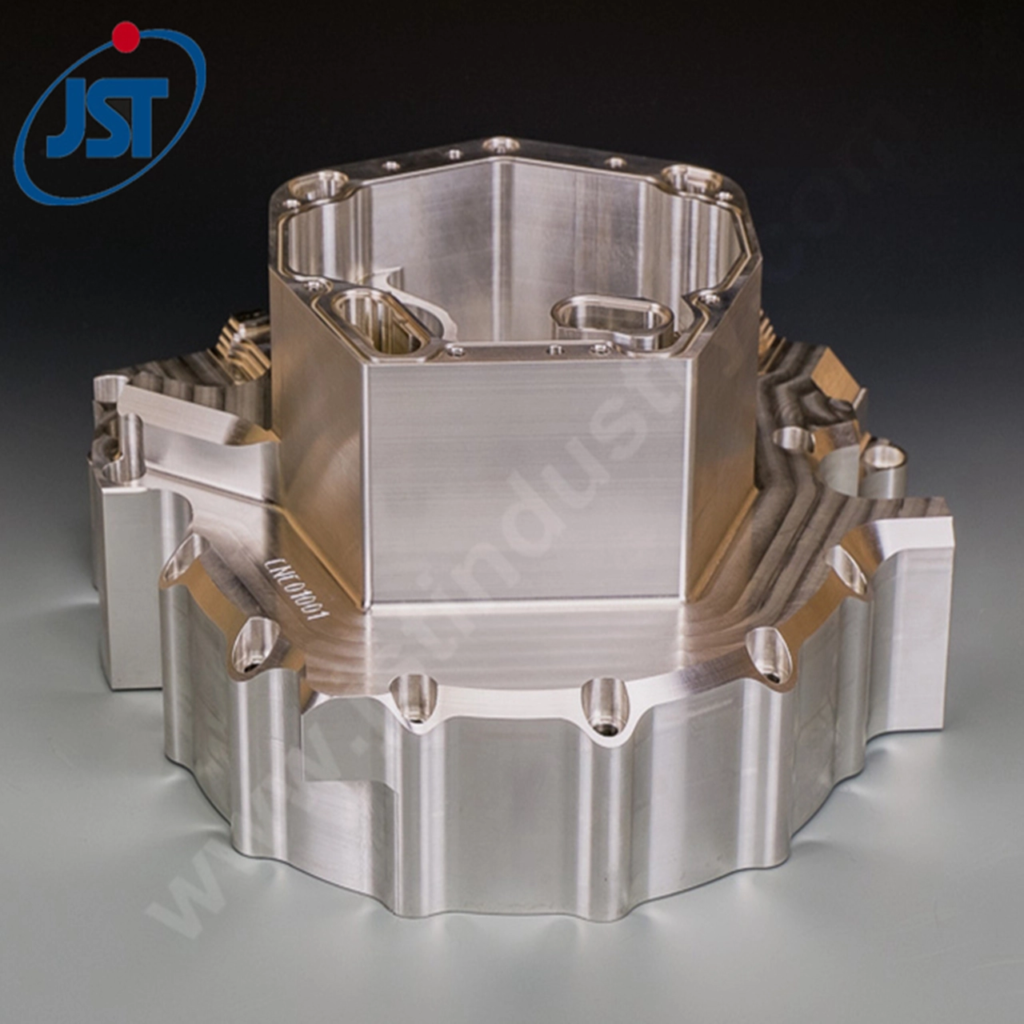

Part Complexity

Think about how hard your part is to make before you start. Some CNC precision machining parts have many shapes or tight corners. These things can make the job harder and cost more. Look at your drawings and see if you really need every detail.

- Simple parts are cheaper and faster to make.

- Hard parts may need special CNC machines or tools.

- More details can make mistakes happen more often.

Note: Making your part less complex can help it be more exact and cost less.

When you design CNC precision machining parts, match the part to what your supplier can do. Some suppliers have CNC machines for hard shapes. Others only make simple parts. Always ask your supplier what their machines can do. This helps you get your CNC precision machining parts on time and just how you want them.

Usinabilité

Machinability means how easy it is to cut a material with CNC machines. Some materials are easy to shape. Others are very hard to work with. You should think about machinability when you pick a material for your CNC precision machining parts.

- Easy-to-machine materials help tools last longer and make parts faster.

- Hard materials need slower work and special tools.

- Hard-to-machine materials can cost more and be less exact.

Ask your supplier if your CNC machining material is easy to machine. Some CNC machining materials, like plastics or aluminum, are easy to cut. Others, like titanium or high-strength alloy, are harder and stronger or resist rust better. Good material choice helps you get the right mix of machinability, accuracy, and strength.

Alert: Picking the wrong cnc machining material can make your parts cost more and not work as well.

When you plan your project, always think about machinability. Easy-to-machine materials give a better finish and more exact parts. Work with suppliers who know about both materials and machining. This helps your CNC precision machining parts meet your needs for quality and performance.

Conclusion

You can pick the right CNC precision machining parts by taking each step. First, think about what you need. Look at technical drawings to see details. Choose the best material for your part. Check if your part is simple or hard to make. See how easy it is to cut the material. Make sure your supplier has good machining skills. This way, you can feel sure about your choice. Ask skilled CNC machining partners if you need help.