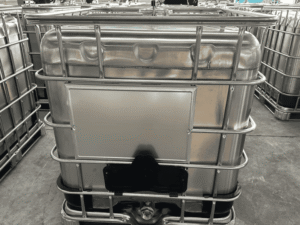

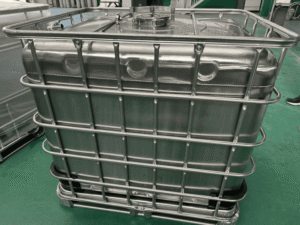

Depósitos IBC de acero inoxidable (JST01)

Introduction to Stainless Steel IBC Tanks

The JST01 1000L stainless steel IBC tank is engineered to meet the demanding requirements of modern liquid storage and transportation. Constructed from premium SUS304 stainless steel, it provides exceptional durability, corrosion resistance, and long-lasting performance. Manufactured with advanced OTC welding robots and complete in-house production, JST ensures high precision and consistent quality.

Widely used in the chemical, pharmaceutical, paint, lubricants, olive oil, and wine industries, the stainless steel IBC tank offers excellent tightness, safety, and reliability. Certified with UN, ATEX (ECM), and anti-static standards, it is ideal for safely storing and transporting both hazardous and non-hazardous liquids.

| Dimensiones exteriores (mm) | 1200X1000X1150(±5) |

| Peso de tara (Kg) | 123 |

| Capacidad nominal (L) | 1000L |

| Densidad máxima (g/cm³) | 1.9 |

| Capacidad de peso máx. (Kg) | 1900 |

| Material | El contenedor interior es SUS304, el marco exterior es de acero galvanizado. |

| Inner container | Weight(Kg):70±2, Lenghth(mm):1140±5, Width(mm):935±5, Height(mm):975±5, Thickness: 2mm. Manhole diameter options: 159+/5mm, 219+/-5mm, 300+/-5mm, 400+/-5mm. |

| Válvula de drenaje: | Válvula de bola DN50, Diámetro interior 50 (mm) |

Advantages of the stainless steel IBC tank

High-quality Materials

The inner container of the stainless steel IBC tank is constructed using SUS304 stainless steel, and the outer frame is galvanized steel.. These materials are renowned for their resistance to corrosion, ensuring that the tanks can endure harsh environments without compromising the integrity of the stored contents. This quality material guarantees long-term durability and reliability, essential for industries that demand secure liquid storage and transport.

Advanced Manufacturing Technology

Our IBC tanks are produced with precision, thanks to advanced welding equipment, including OTC welding robots. This high-tech process ensures that each tank maintains consistent dimensional accuracy and a robust build. By controlling the entire manufacturing process within our own factory, we guarantee superior quality in every tank.

Certifications and Customization

The tanks are certified with UN certification, ATEX certification (ECM), and anti-static certification, making them ideal for the storage and transport of hazardous materials. Additionally, JST offers various manhole diameter options and tank configurations, allowing for customization to suit the specific needs of our clients.

Benefits of the Stainless Steel IBC Tank

Cost Efficiency and Durability

By using high-quality SUS304 stainless steel, our the stainless steel IBC tanks offer extended service life and resistance to corrosion. This reduces the need for frequent maintenance or replacements, making them a cost-effective solution in the long run. Their durability provides a high return on investment for businesses that require secure storage for hazardous or non-hazardous liquids.

Enhanced Safety and Compliance

The stainless steel IBC tanks are designed to meet international safety standards. With certifications such as UN, ATEX, and anti-static, our tanks provide superior protection during the storage and transport of hazardous chemicals. This compliance with global safety regulations reduces risks, ensures legal conformity, and enhances operational safety.

Brand Reputation and Customer Satisfaction

Using high-quality and reliable tanks improves product safety, which in turn enhances the satisfaction of end-users. The durability and performance of our tanks contribute to the reputation of your brand, as they ensure smooth logistics, minimize product failures, and improve customer trust.

Aplicaciones del tanque IBC de acero inoxidable

Industria química

The stainless steel IBC tanks are widely used in the chemical industry for the safe storage and transportation of hazardous chemicals such as acids, solvents, and industrial liquids. The high corrosion resistance and leak-proof design make our tanks the ideal choice for handling chemicals safely, reducing the risk of contamination and spills.

Pharmaceutical and Food Industries

The stainless steel IBC tanks are also used in the pharmaceutical industry for the secure transport and storage of medicinal liquids, where maintaining hygiene and safety is crucial. In the food and beverage industry, including sectors like olive oil and wine production, these tanks help preserve the integrity of the stored products, ensuring that they remain free from contamination.

Paint, Lubricants, and Grease

In the paint industry, the stainless steel IBC tanks offer secure containment for storing paints and coatings. They prevent leaks and contamination, ensuring product safety during transport. Similarly, in the lubricant and grease industry, these tanks provide reliable storage solutions, maintaining the quality and purity of the substances they contain.

1. What materials are used in the Stainless Steel IBC Tanks ?

The inner container of our JST01 IBC tanks is made from SUS304 stainless steel, which is known for its excellent corrosion resistance, durability, and strength. The outer frame is made of galvanized steel, enhancing the structural stability of the tank.

2. What industries can benefit from using the stainless steel IBC tank?

Our IBC tanks are versatile and widely used in a variety of industries, including:

-

Industria química: Safe storage and transport of hazardous chemicals like acids and solvents.

-

Industria farmacéutica: Storage and transport of medicinal liquids while maintaining hygiene.

-

Food and Beverage: Ideal for storing food-grade products such as olive oil and wine.

-

Pintura y revestimientos: Secure containment for paints and coatings to prevent contamination.

-

Lubricants and Grease: Suitable for safely handling lubricants and oils.

3. Are Stainless Steel IBC JST01 Tanks certified for safety?

Yes, our IBC tanks have several important safety certifications, including:

-

Certificación de la ONU: Ensuring the tank complies with international regulations for hazardous material transport.

-

Certificación ATEX (ECM): Certificación para uso seguro en entornos explosivos.

-

Certificación antiestática: Ensures the tank is safe for storing and transporting materials that may create static discharge.

4. ¿Pueden adaptarse los tanques IBC de acero inoxidable a necesidades específicas?

Yes, the stainless steel IBC tanks can be customized according to your specific requirements. We offer various manhole diameter options (159mm, 219mm, 300mm, 400mm) and other configurations to suit the needs of different industries. Please contact us to discuss your customization needs.

Productos relacionados

Póngase en contacto para solicitar información

Contacte con nosotros

Whatsapp:

Correo electrónico:

Tel:

+86-18915758793