Material selection happens early in the design process, but its effects ripple through everything that follows. The wrong choice shows up as parts that cost too much, wear too fast, fail unexpectedly, or simply can’t be manufactured efficiently. Getting it right requires balancing mechanical requirements, environmental conditions, manufacturability, and budget — which, admittedly, sounds easier than it actually is.

This guide breaks down the main considerations when choosing a CNC milling material. No single answer fits every situation, but understanding the tradeoffs makes decision-making considerably clearer.

Why CNC Milling Material Selection Matters

The material isn’t just what the part is made from. It determines machining parameters, tool wear rates, achievable tolerances, surface finish quality, and cost per part. Two geometrically identical designs can have wildly different production costs depending on material choice.

Downstream Effects of Material Decisions

Choosing the wrong CNC milling material creates problems that compound across the entire production process:

Difficult-to-machine materials increase cycle time and tooling costs.

Inappropriate material properties for the application can lead to part failure in the field.

Excessively heavy materials add unnecessary shipping costs and create handling challenges during assembly.

Supply chain availability issues with a specific CNC milling material can cause significant project delays.

Smart CNC milling material selection therefore considers the complete picture—not just whether a material technically meets a specification, but whether it makes practical, economic, and logistical sense for the part’s lifecycle.

Common CNC Milling Material Categories

Materials divide broadly into metals and plastics, with each category containing dozens of specific options. Understanding general categories helps narrow the field before diving into specific grades.

| Material | Key Properties | Aplicaciones comunes | Relative Cost |

|---|---|---|---|

| Aluminum 6061 | Lightweight, corrosion resistant, excellent machinability | General purpose, enclosures, fixtures | Bajo |

| Aluminum 7075 | High strength-to-weight ratio, good fatigue resistance | Aerospace, high-stress components | Medio |

| Acero inoxidable 304 | Corrosion resistant, good strength | Food equipment, medical, marine | Medio |

| Stainless Steel 316 | Superior corrosion resistance | Chemical exposure, marine, medical implants | Medium-High |

| Carbon Steel 1018 | Good machinability, weldable, case hardenable | Structural parts, shafts, fixtures | Bajo |

| Carbon Steel 4140 | High strength, heat treatable | Gears, tooling, high-stress components | Low-Medium |

| Latón C360 | Excellent machinability, corrosion resistant | Fittings, electrical components, decorative | Medio |

| Titanium Grade 5 | Exceptional strength-to-weight, biocompatible | Aerospace, medical implants | Alta |

Aluminum dominates CNC milling work for good reasons — it machines beautifully, costs relatively little, and suits a wide range of applications. Steels offer greater strength and hardness when aluminum won’t suffice. Titanium serves niche applications where nothing else performs adequately.

Plastic Options

Engineering plastics have carved out significant territory in CNC milling material selection:

- Delrin (Acetal) — excellent dimensional stability, low friction, easy to machine

- HDPE — chemical resistant, impact resistant, very affordable

- Nylon — good wear resistance, some moisture absorption concerns

- PEEK — exceptional mechanical properties, expensive, challenging to source

- Polycarbonate — impact resistant, optically clear options available

- PTFE (Teflon) — extremely low friction, chemically inert, soft

Plastics weigh less, resist corrosion naturally, and often cost less than metals. But they lack the strength, stiffness, and temperature resistance metals provide. The application dictates which tradeoffs matter.

Key Factors When Selecting CNC Milling Material

Mechanical Requirements

Start with the basics:

- What loads will the part experience? (Tension, compression, shear, fatigue)

- What stiffness is required?

- Are there hardness or wear resistance requirements?

- What temperatures will the part encounter?

- Is impact resistance important?

A bracket that sees minimal load has different requirements than a gear under continuous stress. Over-specifying leads to unnecessary cost. Under-specifying leads to failure.

Environmental Considerations

Where the part lives matters as much as what forces it experiences:

- Moisture or humidity exposure

- Chemical contact (acids, solvents, fuels)

- UV exposure for outdoor applications

- Temperature extremes (hot or cold)

- Electrical conductivity or insulation needs

Stainless steel makes sense for marine environments. Aluminum works fine indoors but needs protective finishes outdoors. Certain plastics degrade rapidly under UV exposure. Matching material to environment prevents premature failure.

Machinability and Cost

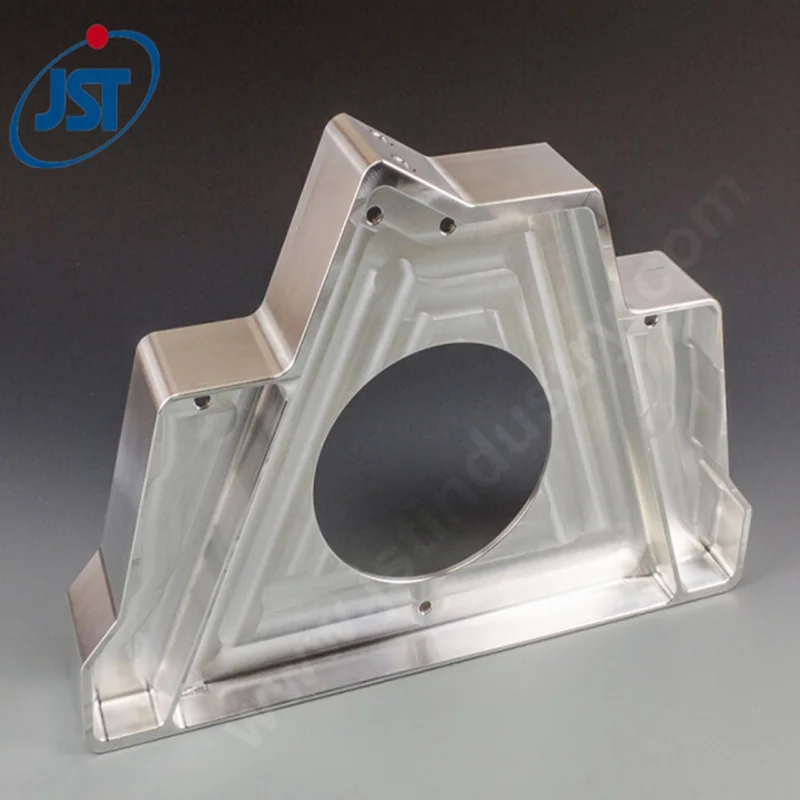

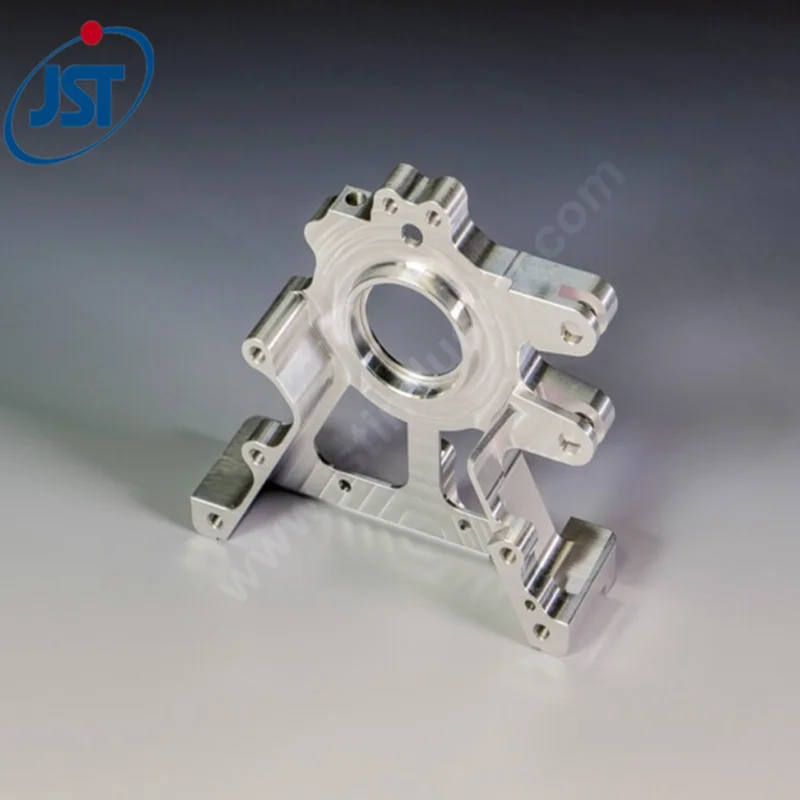

Some materials for Fresado CNC Mecanizado de piezas machine like butter. Others fight every cut. The difference affects production cost significantly.

For common CNC Milling Machining Parts, aluminum alloys generally machine quickly with minimal tool wear. Stainless steels require slower feeds, more rigid setups, and wear through tooling faster. Titanium demands specialized knowledge, tooling, and patience. These differences in machinability show up directly in the quoted price for the final parts.

Material cost itself varies widely too. Titanium might cost ten times more per pound than aluminum — and often takes significantly longer to machine into precision CNC Milling Machining Parts. The combined effect of raw material expense and machining time on the final part price gets dramatic quickly.

Practical Tips for CNC Milling Material Selection

Recommendations That Often Apply

- Default to 6061-T6 aluminum when requirements don’t demand something specific — it’s the workhorse for good reason

- Consider 7075-T6 when aluminum strength isn’t quite enough but weight matters

- Use 304 stainless for general corrosion resistance, 316 when exposure is severe

- Specify free-machining grades (like 303 stainless or 360 brass) when machinability matters more than other properties

- Don’t overlook plastics — they solve many problems metals can’t address economically

Mistakes to Avoid

- Specifying expensive materials “just to be safe” without actual need

- Ignoring machinability impacts on cost and lead time

- Forgetting about finishing — some materials don’t accept certain treatments

- Choosing materials based on past habit rather than current requirements

PREGUNTAS FRECUENTES

What is the most commonly used CNC milling material?

Aluminum 6061-T6 dominates CNC milling work across industries. It offers excellent machinability, good corrosion resistance, reasonable strength, and relatively low cost. The material accepts anodizing and other finishes readily, machines quickly without excessive tool wear, and works for everything from prototypes to production. When requirements don’t specifically demand another material, 6061 usually makes sense.

How does material choice affect CNC milling costs?

Material affects cost through three main channels: raw material price, machining time, and tooling consumption. Difficult materials like stainless steel or titanium require slower cutting speeds, more frequent tool changes, and sometimes specialized equipment — all adding cost beyond just the higher material price. Aluminum parts might cost half what stainless parts cost for identical geometry simply due to machinability differences.

Can any material be CNC milled?

Most engineering materials can be CNC milled, but some present significant challenges. Very soft materials like pure copper or lead gum up tooling. Very hard materials require specialized tooling and rigid setups. Brittle materials risk chipping. Composite materials create unique problems with fiber pullout and tool wear. Technically possible and practically advisable aren’t always the same thing.