CNC Precision Machining: High Precision Manufacturing Expert

As an advanced manufacturing method, CNC precision machining technology plays an important role in many fields with its unique advantages. This article will introduce the advantages, classification, quality control, basic processes and applications of CNC precision machining in detail.

Introduction to CNC Precision Machining-High Precision

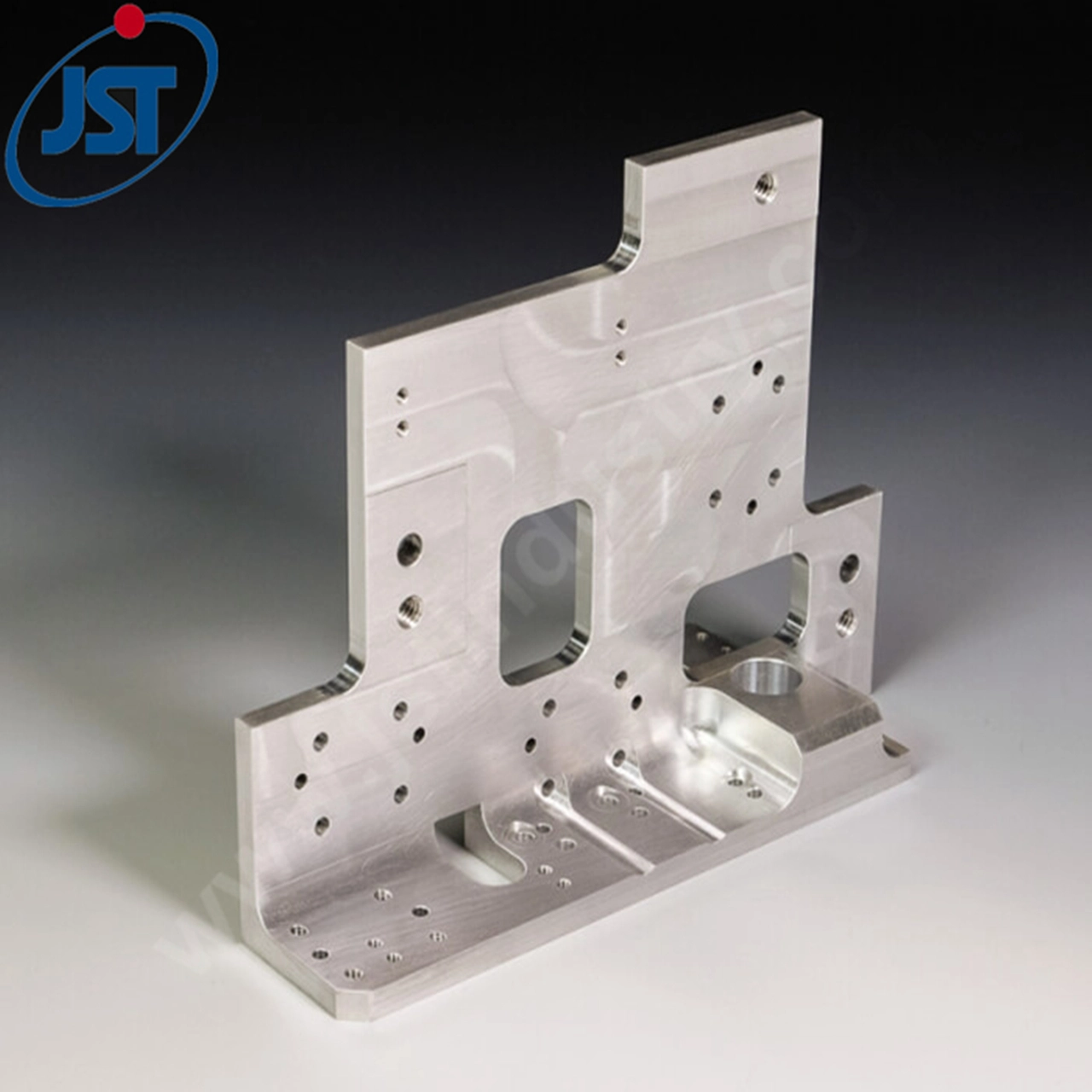

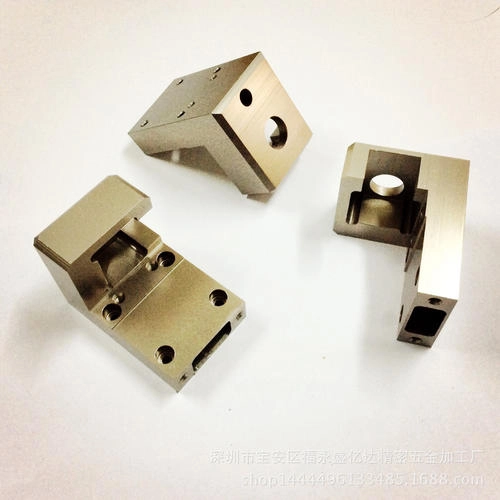

Customized precision machining is an important automated processing technology in modern manufacturing. It uses computer programs to accurately control the movement of machine tools to achieve precision machining of materials such as metals, plastics and wood. CNC precision machining is widely used in modern industry, and the processing materials are mostly steel, stainless steel and aluminum. Processing methods include CNC milling, CNC turning, grinding and welding. We have advanced CNC machining machine tools and technologies. The machine tools will automatically cut, drill or shape the materials according to the code instructions to produce precision parts. We generally strictly control the tolerance to +/-0.01 mm.

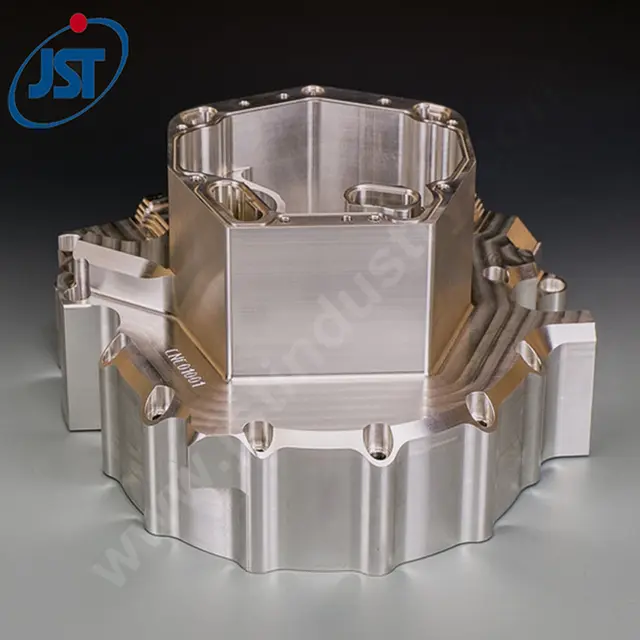

Depending on the processing method and application requirements, CNC precision machining can be divided into many types, mainly including turning, milling, drilling, grinding and electrical discharge machining (EDM).

Advantages of CNC precision machining – Diversification

The advantages of CNC precision machining are mainly reflected in the following aspects:

First, high precision and high efficiency. The use of CNC machining has a high degree of automation, the production cycle is greatly shortened, and the processing accuracy can reach the micron level, meeting the manufacturing requirements of various complex shape parts.

Secondly, CNC precision machining can achieve high repetitive accuracy and reduce material waste.

Application of CNC precision machining technology – professionalism and extensiveness

We are a professional CNC precision manufacturer, such as custom precision CNC machining engine parts, automobile and motorcycle parts, aircraft engines, etc. With rich experience, we can guarantee the professional quality and competitive price of our products.

Automobile body manufacturing:

CNC machining technology also plays an important role in the field of automobile body manufacturing,

CNC machining is used to manufacture engine cylinder heads and gearbox gears. Through CNC precision machining, these parts have extremely high dimensional accuracy and surface finish to ensure smooth operation.

Aerospace:

These parts require high strength and lightweight. Therefore, structural parts such as fuselage frames and wings of aircraft need to use CNC precision CNC machining.

For example, a custom precision CNC machined part for an aircraft engine is a capsule filter made by laser drilling. The difficulty of this precision CNC machined part lies in the small holes with a diameter of 0.10 mm and the large holes with a thickness of 0.04 inches. There are 800 small holes with a diameter of 0.10 mm.

Other applications:

CNC precision machining is essential in various applications, including the production of medical devices like artificial joints and surgical tools, as well as smartphone casings and circuit boards in electronics. This showcases the broad utility of CNC technology in meeting the precision component demands across diverse industries.

JST has decades of work experience and professional equipment and technology, so there is no need to worry about quality and supply. We have stable customers in the United States and European countries, so our professionalism and experience are excellent.

If you are interested, you can click on the specific product details for more information. Feel free to contact us.