Steel Machining Parts – High Strength Applications and Surface Finishing Technology

In today’s industrial world, steel is already a core material in the fields of construction and mechanical manufacturing. Steel Machining Parts, with its excellent strength and plasticity, is indispensable for the development of industries such as precision instruments and heavy machinery. This article will explore in depth the application areas of high-strength steel and how surface treatment technology can improve its performance and aesthetics.

Application Areas of High-Strength Steel

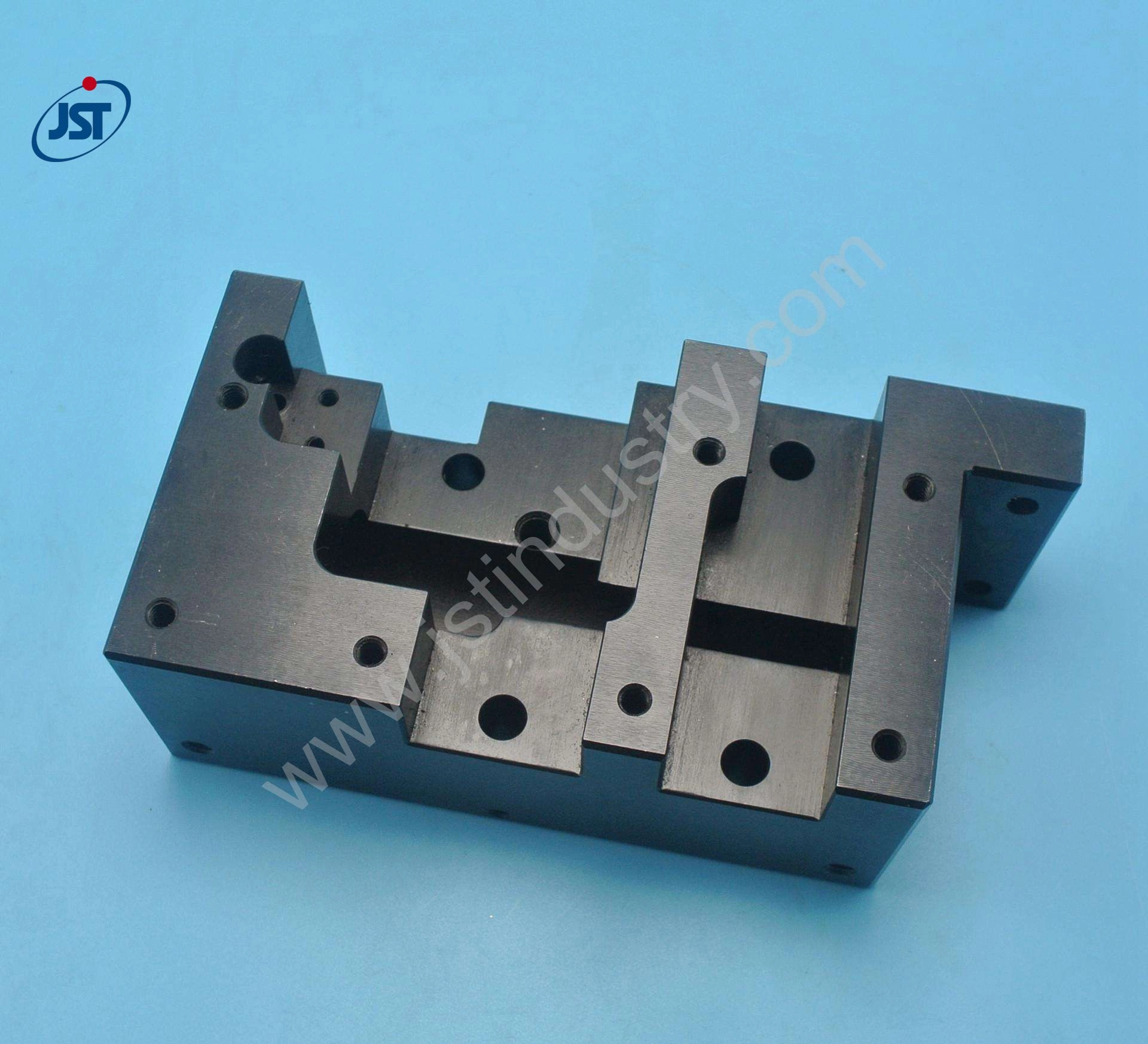

Precision Manufacturing in the Automotive IndustryThe automotive industry has extremely high requirements for the accuracy and strength of parts. Therefore, precision High Strength Steel plays a vital role in this field. For example, key parts such as engine parts, gearbox components, and suspension systems require precision machining of steel machining parts. These parts must not only withstand huge mechanical stress, but also ensure long-term stability and durability.

As an OEM manufacturer of precision custom steel machining parts, we have manufactured many steel machining automotive parts, most of which are exported to Italy, Germany and France, so we have a lot of experience in precision manufacturing in the automotive industry.

Precision Machining in the Aerospace Field:

The requirements for materials in the aerospace field are even more stringent. Precision Custom Steel Machining Aerospace Parts need to have extraordinary strength and lightness to adapt to extreme working environments. Therefore, high-precision machining of steel machining parts is the key to ensuring flight safety, such as aircraft landing gear, satellite structural parts, etc.

Fine Machining of Medical Devices:

In the field of medical devices, surgical tools, orthopedic implants, etc. also require precision machining parts of high-strength steel, which not only requires extremely high machining accuracy, but also requires the material to have excellent biocompatibility and corrosion resistance. These characteristics make High Strength Steel an ideal choice for manufacturing high-end medical devices.

Importance of Surface Treatment Technology

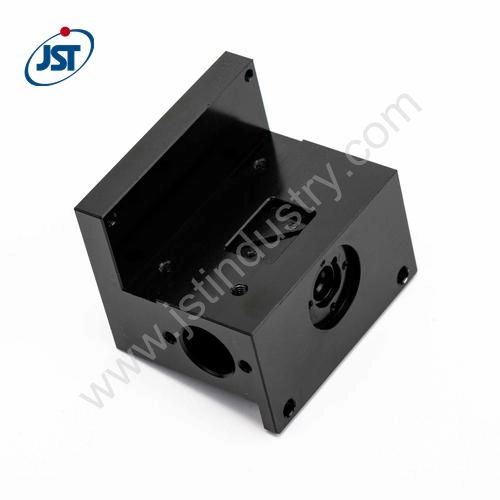

Black Oxidation Treatment:

We generally use black oxidation treatment when making custom carbon steel machining parts. After black oxidation treatment, Steel Machining Parts not only obtains a beautiful black appearance, but more importantly, this surface treatment technology significantly improves the corrosion resistance and wear resistance of the parts. This technology forms a dense oxide film on the metal surface through chemical methods, effectively isolating air and moisture, and extending the service life of the parts.

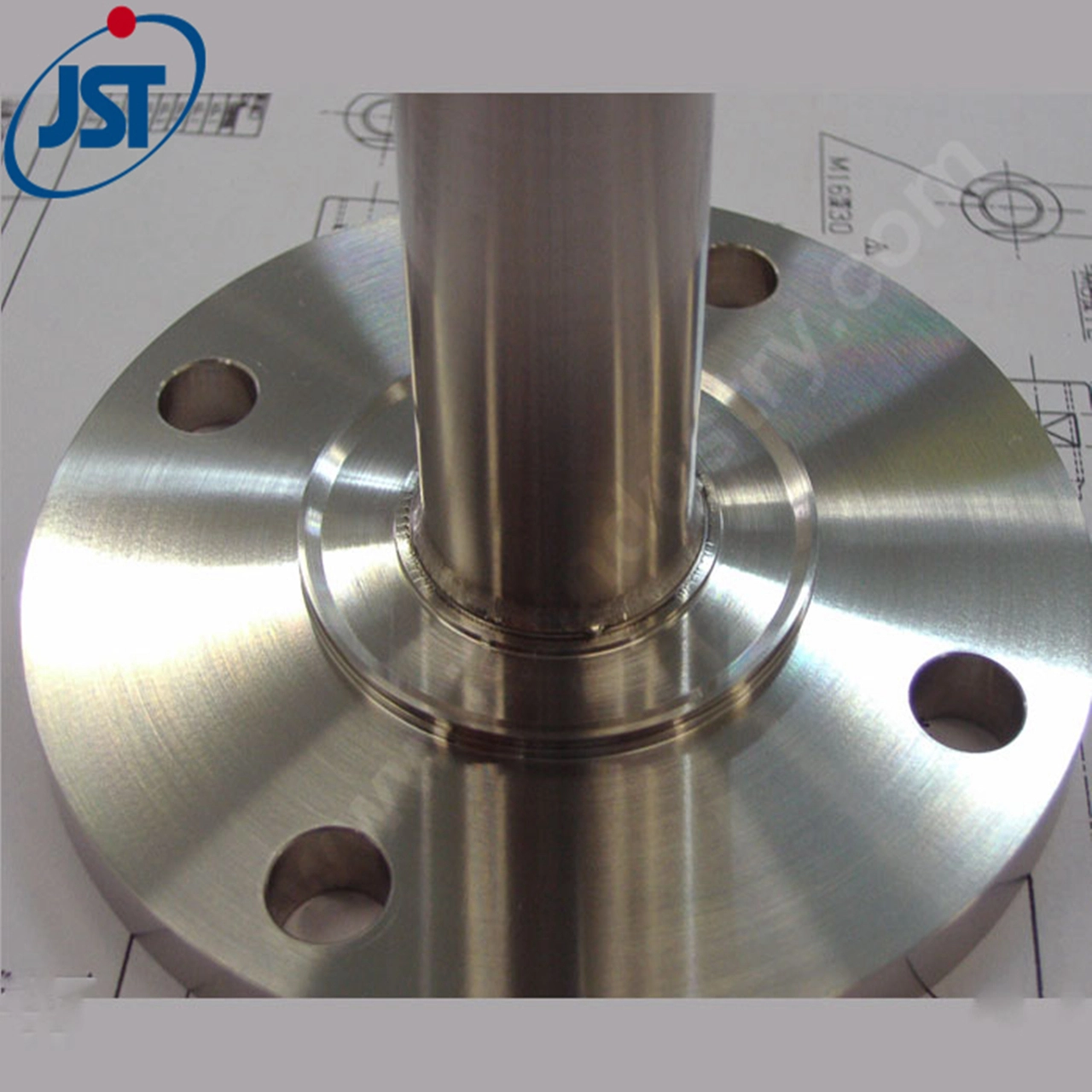

Satin polishing technology:

Satin polishing provides steel machining parts with a soft gloss and low reflectivity, which is particularly important in applications where light reflection needs to be reduced. In addition, the satin polished surface is easier to clean and maintain, which is conducive to improving the surface quality of the parts.

Surface hardening treatment:

For steel machining parts that need to withstand high loads or high wear, such as gears and bearings, surface hardening treatment is an effective means to improve their performance. Through processes such as carburizing and nitriding, a harder protective layer can be formed on the surface of the parts, thereby improving their wear resistance and load-bearing capacity. For example, carburizing + black oxidation is used for surface treatment.We will choose different surface treatment methods according to different application scenarios and performance requirements, which has a great relationship with the performance and aesthetics of the parts.

Future Outlook

With the continuous advancement of science and technology, the application fields of steel machining parts will be more extensive, and the requirements for material performance will become higher and higher. Whether in the traditional automotive and aerospace industries or in the emerging medical equipment and optical fields, the demand for High Strength Steel Surface Quality Automotive Parts will continue to grow. The development of precision machining technology and surface treatment technology will provide more possibilities for the application of these high-strength steels. We look forward to seeing more innovations and breakthroughs in the future to bring more value to industrial manufacturing.

If you want to learn more, you can click on the relevant products.Welcome to contact us.