PRODUCT CATEGORY

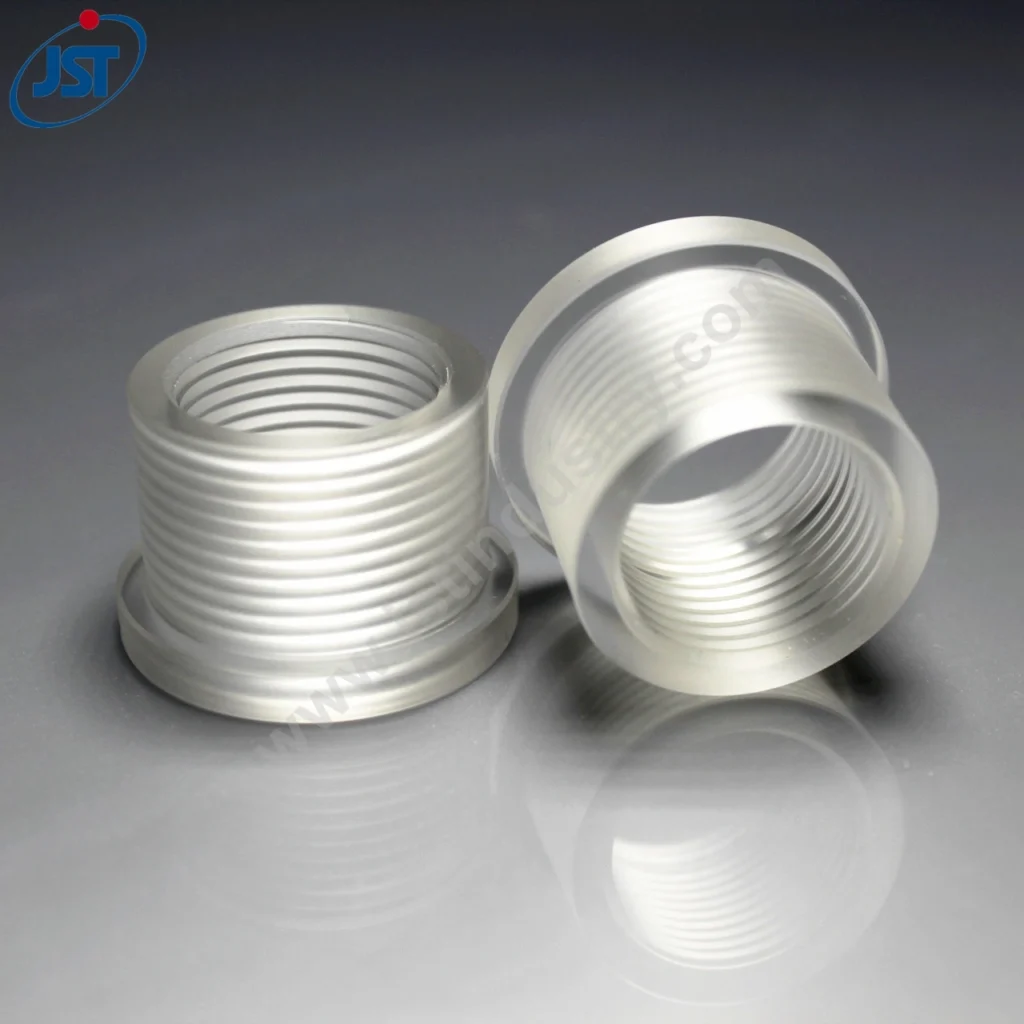

The OEM CNC turning plastic parts, crafted on NC lathes, serve the medical vision system equipment industry.

– Made from acrylic material, these parts feature a G 3/4″ thread.

– With a MOQ of 5000 PCS and a lead time of 15 days, these parts meet strict production timelines.

– Precision is ensured with a tolerance of +/-0.02mm and a surface finish of Ra 0.8.

– JST, known for its reliable supply, specializes in precision CNC turning plastic parts for medical applications.

For inquiries on OEM precision CNC turning plastic parts, reach out to JST for a quotation.

Application of OEM Precision CNC Turning Machining Plastic Parts

1. CNC Turning Plastic Parts for Medical Vision System Equipment

This kind of OEM precision CNC turning Plastic Parts has been majorly applied within the industry of Medical Vision System Equipment. It plays a critical role in building and ensuring the proper functioning of several medical apparatuses which are supposed to maintain highly pinpointed levels of precision and accuracy.

2. CNC Turning Machining Plastic Parts for Optical Components

Precision plastic parts are used as lenses, prisms, and other optical components in medical imaging and vision systems. The required quality of such parts is high clarity and precision.

3. CNC Turning Plastic Parts for Mechanical Components

This same precision is required in other uses of the parts in the mechanical systems of medical devices. Handles, brackets, and other structural elements are required to be tolerant of preciseness, ensuring both smooth operation and the engineering design of the devices.

4. CNC Turning Plastic Parts for Medical devices

On the other hand, precision CNC turning plastic parts can be used to house the electronic components of medical devices. The housings, which have to be designed in such a way that they protect the electronics inside -must be sensitive- and provide for suitable connections and interfaces.

5. CNC Turning Plastic Parts for Interfaces and Connectors

For medical vision systems, it is critical to have precise interfaces and connectors so that different components can work in harmony. These specific requirements can be met by designing CNC turned plastic parts, which will provide a reliable and safe connection.

6. CNC Turning Plastic Parts for Specialty Components

Owing to the variation in medical devices, many times there is a requisite for custom components that may be attuned particularly to the application. CNC turning makes it viable to produce these parts of the composition with that level of accuracy required for medical application.

Material Property Requirements

The choice of material for these plastic parts, manufactured using precision CNC turning, is acrylic(PMMA). Acrylic is known for its optical properties and strength. The following are a few of its essential properties that make acrylic most appropriate for medical vision system equipment:

1. Optical Clarity

Acrylic features excellent optical clarity (a desirable characteristic in components through which imaging takes place in a mdical device). It allows high light transmission with minimal distortion.

2. Strength and Durability

Acrylic is strong and durable. High tensile strength makes it even more resistant to impact. Since it is plastic, this material would be appropriate for those parts subjected to stress or impact.

3. Chemical Resistance

Acrylic has resistance to many chemicals. Hence, it is important, especially in medical applications, as parts may come into contact with different cleaning solutions or chemicals used in the device.

4. Temperature Tolerance

Acrylic does not work for high-temperature applications. However, it performs well at moderate temperatures, which relates to most medical equipment without extreme heat exposure.

5. Machinability

Acrylic is relatively easy to machine. This allows highly complex shapes, and high precision in tolerances can be met through this material. Both of these are critical features in medical apparatus.

6. Aesthetics

Acrylic can be polished to a high gloss finish. For this reason, it finds a higher application in medical apparatus for aesthetic as well as good surfaceness reasons.

7. Biocompatibility

For applications in which plastic parts may come into direct contact with the human body, acrylic is known for its biocompatibility, proving the material safe for use in medicine.