CNC milling aluminum: efficient manufacturing technology for lightweight materials

CNC milling aluminum is an efficient and accurate manufacturing technology that shows its advantages and application potential in many aspects. Aluminum is a lightweight metal with excellent thermal and electrical conductivity and is easy to machine. There are several types of alloys such as 6061, 7075, 6063 and 2024, each with different properties for different production requirements.

Types of aluminum:

6061 aluminum alloy:

This alloy is relatively easy to machine, corrosion resistant and has excellent mechanical and welding properties. Therefore, it is widely used in the manufacturing industry. It has sufficient strength and excellent stability, making it suitable for various aircraft and automotive components.

7075 aluminum alloy:

This alloy has high strength and hardness and is suitable for applications where high forces must be applied. For example, aircraft structural components and high-performance bicycle frames can be strong enough with 7075 aluminum alloy.

Aluminum alloy 6063:

This alloy has excellent extrusion properties and is often used for architectural profiles such as doors, window frames and balustrades. It is also very effective as a surface treatment and can be anaodized to change its color.

2024 aluminum alloy:

has excellent fatigue strength and corrosion resistance and is suitable for components operating at high speeds. In the aerospace industry, it is often used for basic components such as aircraft structural parts and fuselage frames.

Processing technology:

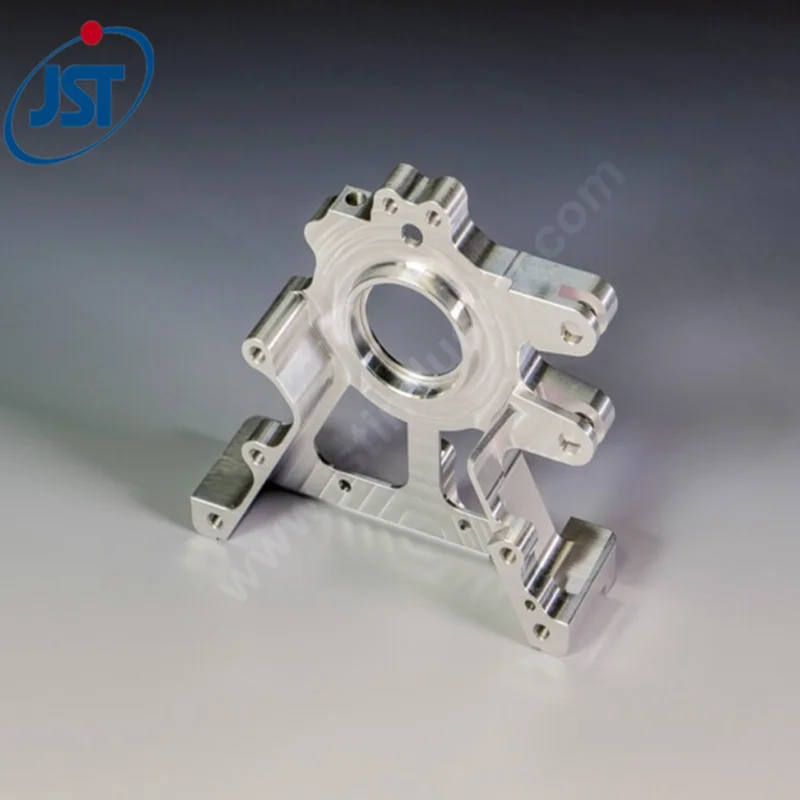

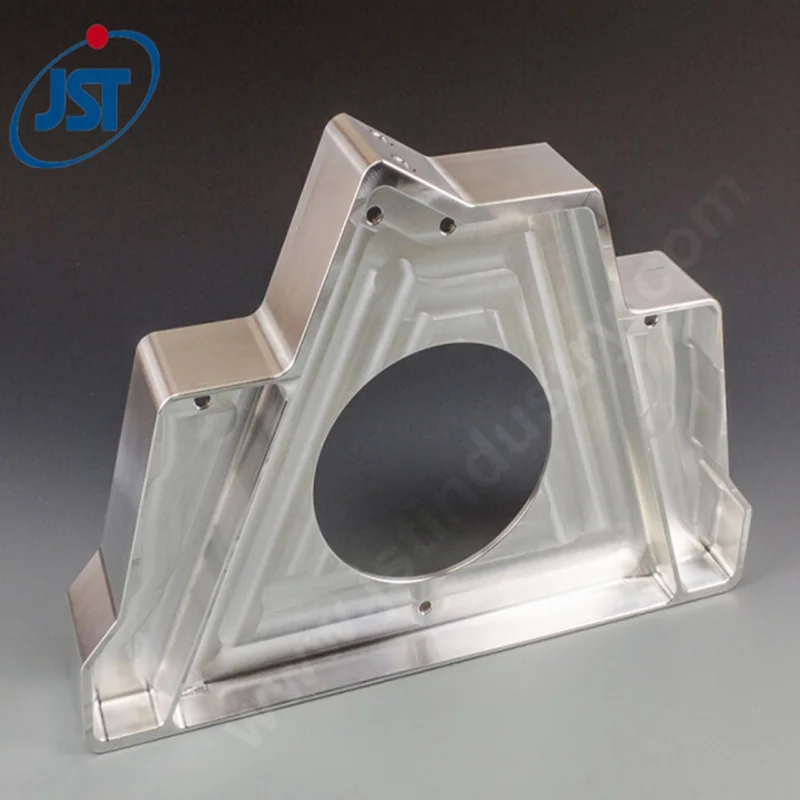

CNC milling aluminum is the process of fixing the aluminum workpiece and using a rotating multi-point tool to move along the axial direction to remove material. It is suitable for the processing of flat and irregular shapes, and can produce detailed features and surface finishing.

Application areas:

In the aerospace field:

CNC milling aluminum we provide help aircraft reduce weight while maintaining high strength and precision. These parts include aircraft fuselage parts, wing structures, engine components, and interior parts. Our processing equipment, such as three-axis machining centers, can produce precise CNC milled aluminum parts, such as the LED housing on the aircraft, which is made of AL6061-T6 aluminum alloy and has a sandblasted surface.

In the automotive manufacturing industry:

CNC milling aluminum play a key role in lightweighting vehicles. These parts include engine blocks, gearbox housings, suspension system components, etc., which help improve the fuel efficiency and performance of automobiles.

In the electronics industry:

CNC milled aluminum parts are widely used. They enhance the durability of electronic products and improve heat dissipation efficiency.

In the construction industry:

Our aluminum parts are used to manufacture window frames, door frames and various decorations. They are popular in the construction field because they are not easy to corrode and have beautiful appearance.

In the medical field:

The precision CNC milled aluminum parts we produce are used to manufacture surgical tools and medical devices. These parts meet the strict requirements of the medical industry for high precision and biocompatibility.

In the new energy sector:

CNC milling aluminum are used in the production of photovoltaic and wind power equipment, such as brackets and generator components, ensuring stable operation and a long service life of the equipment. Our custom CNC milled aluminum parts are used in new energy vehicles in particular and are made of aluminum alloy with clear anodized surfaces. These parts are widely used in medical devices and automotive components, where our tolerance control can achieve an accuracy of ±0.02 mm.

If you have any questions about CNC milling aluminum and its parts, please feel free to contact us.