Brass machining – precision customized application

Precision brass processing is a high-precision metal processing technology that is widely used in many fields such as automobiles, electronics, and mechanical manufacturing. This article will start from the characteristics of precision brass processing in terms of material selection, performance requirements, processing technology and precision, as well as its application.

Material selection:

Brass( Hp59-1):

This material has been widely used in many fields such as new energy vehicles, electronics, and mechanical manufacturing. It not only has good mechanical properties and can withstand certain mechanical loads, but also has high electrical conductivity and thermal conductivity. In addition, brass also has good machinability and is easy to perform various mechanical processing, such as cutting, drilling, and forming. Brass has a bright gold color, which means that brass machined parts can be used basically without additional surface treatment. Therefore, parts made of brass also have a certain aesthetics.

Bronze:

Bronze is a copper-tin alloy. It has excellent wear resistance and corrosion resistance, and is used when manufacturing wear-resistant and corrosion-resistant parts.

Brass alloy:

Brass alloy refers to the addition of other alloying elements to brass to improve its performance. For example, adding aluminum can increase the strength and hardness of brass, while adding manganese can improve its corrosion resistance.For materials, they should be selected according to the special requirements of the application field and their performance should be optimized.

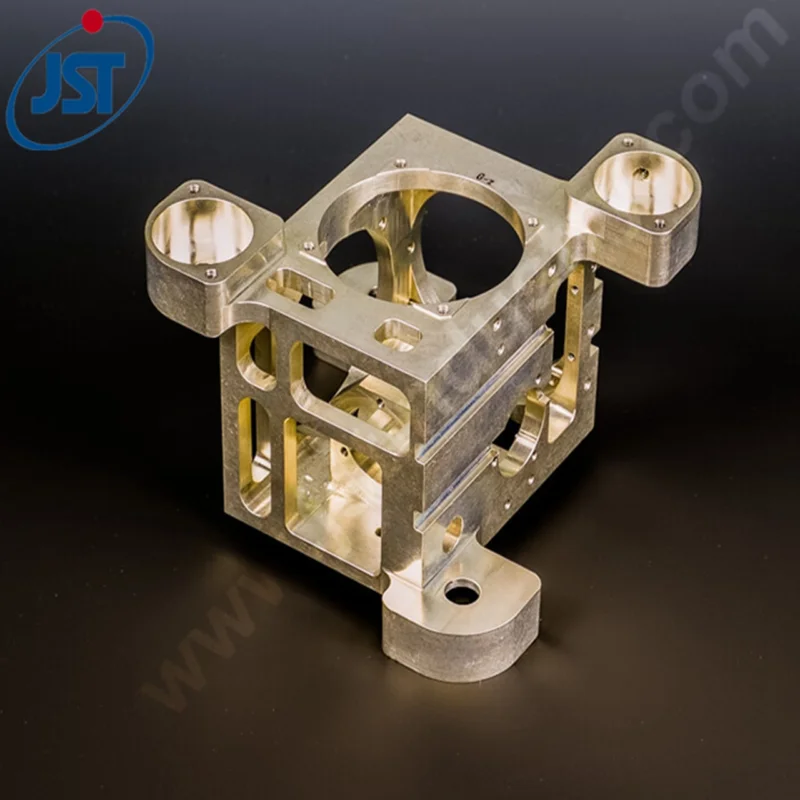

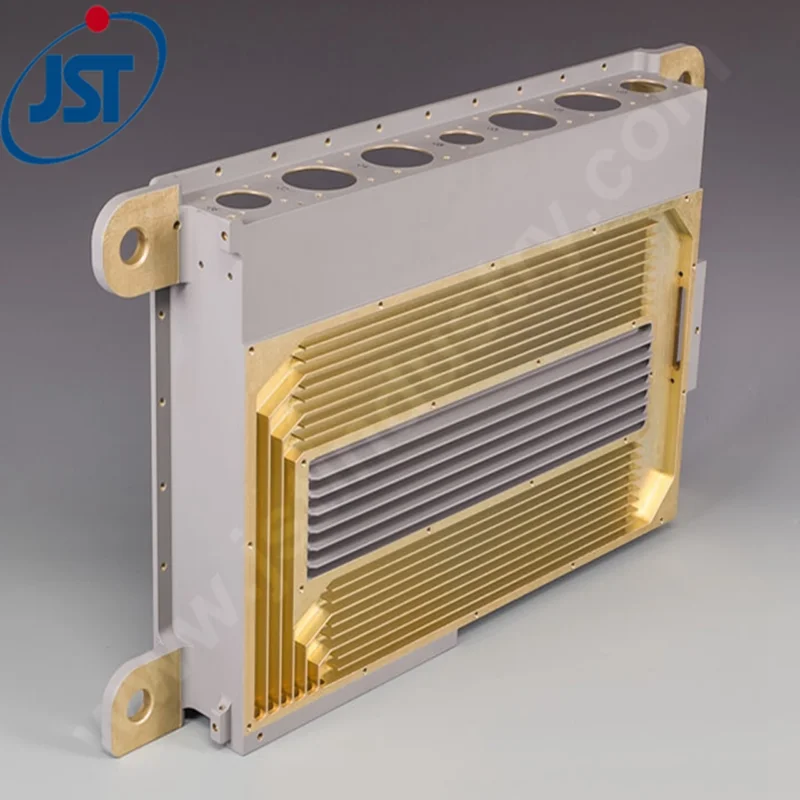

Processing technology and precisionCNC processing technology:

JST has produced many customized brass machined parts, especially automotive parts and motorcycle parts. We have more than 10 years of experience in manufacturing precision CNC milled parts and precision CNC milled brass parts, and we conduct 100% inspection on key dimensions. When processing, we use advanced CNC processing technology to achieve precise detail processing, maintain a surface roughness of Ra 1.6, and a tolerance of +/-0.02mm. Surface treatment methods include polishing, sandblasting, powder coating, etc.

Application

Customized precision brass processing:

JST is an OEM manufacturer. We have professional equipment and production processes to operate and produce these brass machined automotive parts according to drawings or samples. For this kind of customized brass processing, we have rich experience and competitiveness, and more than 80% of our products are exported to Germany, Italy and the United Kingdom.

Automotive field:

Brass is used to make various parts in the engine, such as cylinder heads, crankcases, valve covers, etc. In automotive hydraulic systems, brass is used to make parts such as pipes, valves and connectors. These parts require good corrosion resistance and mechanical properties.Electrical connectors: The conductivity of brass is ideal for making automotive electrical connectors.

Decorative components:

Decorative components such as dashboard decorations and door handles can also be processed with brass. Its beautiful appearance and corrosion resistance make it an ideal material for decorative parts.Precision brass processing automotive parts and precision brass milling parts are important departments of our company. For brass processing, we can accept both small and large orders, and we can also make samples for your testing first.

If you are interested in precision brass processing, you can click on the relevant products to learn more.Welcome to contact us.