CNC Turning Service

JST provides precision CNC turning service and the accuracy can be controlled within +/- 0.005mm.

What is CNC Turning?

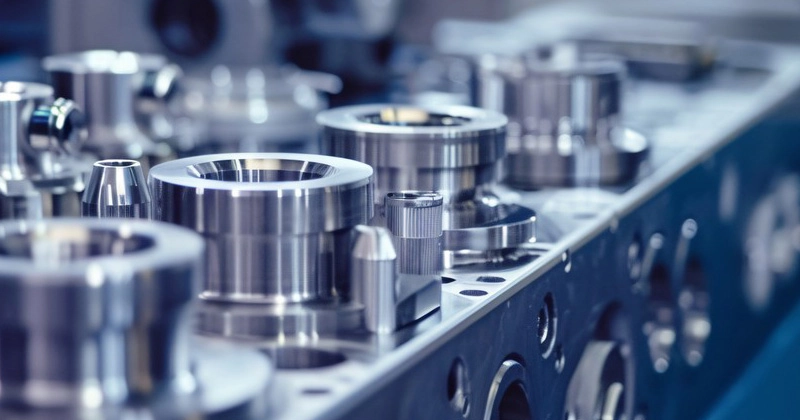

CNC (Computer Numerical Control) turning is a advanced precision machining process where a cutting tool removes material from a rotating workpiece to create cylindrical, conical, or curved parts. Known for its high repeatability, exceptional accuracy, and efficient production speeds, it is a cornerstone of modern manufacturing.

At JST, we leverage state-of-the-art CNC lathes and a seasoned team of engineers to master this technology. Whether for simple bushings or complex rotationally symmetric components, we transform your designs into tangible CNC turning parts that meet the most stringent standards.

Main CNC Turning Materials

Which material is right for your project? The ideal choice balances strength, weight, corrosion resistance, and budget. Explore our most commonly machined materials below and leverage our expertise for your application.

Aluminum Materials

JST has advanced CNC turning equipment and an experienced technical team, which can accurately process various aluminum alloy materials, including 6061, 7075, etc.

We can perform customized processing according to customer requirements to ensure that the dimensional accuracy and surface quality of the parts reach the best level.

They are widely used in aerospace, automobile manufacturing and other fields.

Copper Materials

JST has professional CNC turning capabilities and can efficiently and accurately process various copper alloy materials, such as copper, brass, etc. Our equipment and technology can ensure the processing quality and surface smoothness of copper material parts, and are suitable for electronic products, communication equipment and other fields.

Stainless Steel Materials

JST has rich processing experience and advanced equipment, and can efficiently process stainless steel materials, such as 304, 316, etc. Our technical team can ensure the processing accuracy and surface finish of stainless steel parts, which are suitable for high-demand fields such as medical devices and food processing equipment.

Steel Materials

JST has advanced CNC turning equipment and a professional technical team, which can accurately process various steel materials, such as carbon steel, alloy steel, etc. Our processing capabilities and quality control system can ensure the processing quality and dimensional accuracy of steel material parts, which are suitable for mechanical equipment, automobile parts and other fields.

Alloy Materials

JST has rich processing experience and advanced equipment, and can efficiently process various alloy materials, such as titanium alloys, nickel alloys, etc. Our technical team can perform customized processing according to customer needs to ensure the processing quality and performance of alloy material parts, which are suitable for high-end fields such as aerospace and energy.

All CNC Turning Materials Parameter

| No. | Material | Description |

|---|---|---|

| 1 | 1018 Steel | General purpope 1018 steel is the most prominent of the carbon steels. The low carbon content makes this steel ductile and suitable for forming and welding. |

| 2 | Alloy Steel 4140 | Additional chromium makes this steel corrosion and fracture resistant. |

| 3 | Aluminum 2024-T3 | 2024 aluminum is used when a high strength-to-weight ratio is required, such as for gears, shafts and fasteners. It is nonmagnetic and heat treatable. |

| 4 | Aluminum 5052 | Corrosion resistant aluminum frequently used in sheet metal applications. |

| 5 | Aluminum 6061-T6 | Aluminum 6061 is easily machined and lightweight, perfect for prototypes, military and aerospace applications. |

| 6 | Aluminum 6063-T5 | Commonly used outdoors as architectural trim, railings, and door frames, 6063 aluminum has better machinability than 3003. It is nonmagnetic and heat treatable. |

| 7 | Aluminum 7075-T6 | Harder and higher strength aluminum alloy good for high-stress parts. |

| 8 | ASTM A36 | General purpose, hot rolled steel plate. Great for structural and industrial applications. |

| 9 | Brass C360 | A highly machinable brass. Great for prototyping gears, fittings, valves and screws. |

| 10 | Copper 101 | Commonly known as Oxygen-Free Copper, this alloy is great for electrical conductivity. |

| 11 | Stainless Stee 17-4 | A high strengh, corrosion resistant stainless alloy. Easily heat treatable. Typically used in medical equipment. |

| 12 | Stainless Steel 303 | A machinable, corrosion-resistant material. |

| 13 | Stainless Steel 304 | A machinable, corrosion-resistant material. |

| 14 | Stainless Steel 420 | Contains more carbon than stainless 410 to give it increased hardness and strength when heat treated. Offers mild corrosion resistance, high heat resistance, and improved strength. |

| 15 | Titanium Grade 2 | High strength, low weight, and high thermal conductivity. Ideal for applications in the aerospace and automotive industries. |

| 16 | Zinc Sheet Alloy 500 | Continuous-cast alloy. Has good electrical conductivity and is highly resistant to corrosion. This alloy is readily treatable for painting, plating and anodizing. |

| 17 | Acetal (White/Black) | Acetal resin with good moisture resistance, high wear-resistance, and low friction. |

| 18 | Acrylic (PMMA) | A clear glass-like plastic. Good wear and tear properties. Great for outdoor use. |

| 19 | Black ABS | High strength engineering plastic, used for many commercial products. |

| 20 | Nylon 6/6 | Offers increased mechanical strength, rigidity, good stability under heat and/or chemical resistance. |

| 21 | PEEK | Offering excellent tensile strength, PEEK is often used as a lightweight substitute for metal parts in high-temperature, high-stress applications. PEEK resists chemicals, wear and moisture. |

| 22 | Polycarbonate (PC) | A clear or colored, light-weight, glass-like plastic than can be machined. |

| 23 | PTFE (Teflon) | This material surpasses most plastics when it comes to chemical resistance and performance in extreme temperatures. It resists most solvents and is an excellent electrical insulator. |

Surface Finishes for CNC turning Parts

As-Machined

Default surface from CNC; visible tool marks; roughness set by tool & parameters

Smooth

Abrasive tools/media remove top layer, reducing roughness & imperfections

Bead Blasting

Fine glass beads/media create smooth matte/satin finish; removes tool marks

Anodizing

Electrochemical thickening of natural Al oxide; clear or dyed; adds corrosion resistance

Polishing

Mechanical removal of material to create smooth/glossy or mirror-like surface

Powder Coating

Dry powder applied electrostatically & cured; durable, uniform, protective layer

Brushing

Abrasive belts/brushes produce uniform directional texture; satin/matte look

Electroplating

Blast with fine glass beads/media, removes tool marks & surface imperfections; mooth, matte, satin finish

Passivation

Chemical treatment for stainless/metals; removes free iron, enhances corrosion resistance

Heat Treating

Heating & cooling to alter hardness/strength/toughness; hardens outer layer

Electropolishing

Electrochemical removal smoothes & brightens; high-gloss, reflective; improves corrosion res.

Chromating

Chemical conversion coating on Al; provides corrosion resistance & paint primer

Sandblasting

Abrasive media (sand, Al₂O₃, etc.) cleans/textures; rougher than bead blasting

Tumbling

Vibratory finishing with abrasive media; polishes, deburrs, smooths complex/small parts

Laser Engraving

Laser beam etches permanent markings (logos, text, serial numbers); no overall finish change

Black Oxide

Chemical coating on steel yields black matte finish; moderate corrosion & glare reduction

CNC Turning Standards & Tolerances

At JST, we understand that precision is not just a metric—it’s the foundation of performance for your CNC turning parts. Our commitment to dimensional accuracy ensures that every component we produce not only meets specifications but also delivers reliable function in your most demanding applications.

√ Standard Precision Machining: We routinely maintain exceptionally tight tolerances between ±0.01 mm to ±0.05 mm (±0.0004″ to ±0.002″), guaranteeing high dimensional accuracy and interchangeability for your projects.

√ Flexible, Customer-Centric Tolerances: Beyond our standard range, we adapt our CNC turning processes to your specific needs. We can adjust machining parameters and control tolerance ranges based on your unique application scenarios and project requirements.

√ Wide-Range Part Manufacturing: Our advanced CNC turning equipment offers high precision and stability across a vast spectrum of sizes. We expertly machine parts with diameters from a minute 0.5mm up to a substantial 500mm, and handle lengths ranging from a few millimeters to several meters.

| Turning Area | Dimension | Tolerance |

|---|---|---|

| Outer diameter | 0.5–3 mm | ±0.01 mm |

| Outer diameter | 3–6 mm | ±0.01 mm |

| Outer diameter | 6–30 mm | ±0.02 mm |

| Outer diameter | 30–120 mm | ±0.03 mm |

| Outer diameter | 120–400 mm | ±0.05 mm |

| Inner diameter | 0.5–3 mm | ±0.02 mm |

| Inner diameter | 3–6 mm | ±0.02 mm |

| Inner diameter | 6–30 mm | ±0.03 mm |

| Inner diameter | 30–120 mm | ±0.05 mm |

| Angle | 0–50 mm | ±30′ |

| Angle | 50–400 mm | ±15′ |

| Curving Radius & Bevel height | 0.5–3 mm | ±0.10 mm |

| Curving Radius & Bevel height | 3–6 mm | ±0.20 mm |

| Curving Radius & Bevel height | >6 mm | ±0.25 mm |

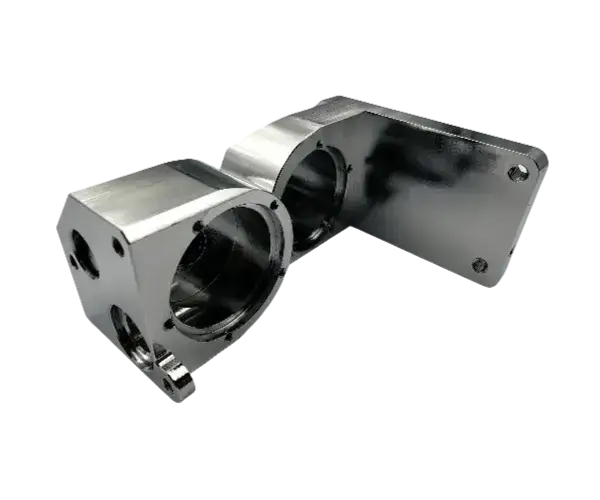

CNC Turning Parts We Can Process

As a processing company with many years of CNC turning service experience, JST is proud to display the CNC turning parts and samples of various materials that we have produced. Our technical team and advanced equipment ensure that we can process a variety of materials, including but not limited to:

- Aluminum alloy parts: We have successfully processed various aluminum alloy parts, such as aerospace parts, automobile engine parts, etc., which are lightweight and corrosion-resistant.

- Stainless steel parts: We also have extensive experience in stainless steel materials. We have processed stainless steel parts for use in medical devices, food processing equipment and other fields, with excellent corrosion resistance and mechanical properties.

- Copper alloy parts: Our processing capabilities also cover copper alloy materials. We have processed various copper alloy parts, such as electronic connectors, conductive devices, etc., which have good electrical conductivity and wear resistance.

- Steel parts: Steel materials are another area of our expertise. We have processed various carbon steel and alloy steel parts, which are used in mechanical equipment, automobile parts and other fields, with excellent mechanical strength and wear resistance.

- Plastic parts: In addition to metal materials, we are also able to process various plastic parts, such as POM, PTFE, PEEK, etc., which are used in electronic product casings, engineering parts and other fields, and are lightweight and insulating.

Application

The applications for precision CNC turned parts are nearly limitless. From aerospace and automotive to medical and consumer electronics, see how our expertise has been applied across industries—and imagine how we can help bring your design to life.

Medical Devices

Help Center

FAQ

Q: What are the machining techniques/processes of CNC Turning Service?

A: Turning : This is one of the most basic machining techniques of CNC Turning Services. The workpiece is turned and cut with a cutting tool to give it symmetry in the axial direction. Turning can be used to make a variety of shapes including shafts, tubes and face parts.

Q: What types of parts are suitable for CNC Turning services?

Q: What equipment is required for CNC Turning services?

A: CNC Lathe: As the core equipment of the CNC Turning service, CNC lathes are capable of rotating workpieces and machining them with cutting tools, featuring high precision and efficiency.

Automatic feed mechanism: The automatic feed mechanism is used to control the relative motion of the workpiece and cutting tool to automate and precisely control the machining process.

Cutting tools: CNC Turning service requires the use of various cutting tools, such as turning tools, drills, boring tools, etc., to meet the needs of different parts processing.

Clamps and fixtures: These are used to clamp and hold workpieces to ensure stability and precision in the machining process, while minimizing workpiece deformation and vibration.

CNC control system: CNC control system is used to control the movement and machining parameters of the CNC lathe, including speed, feed, tool path, etc. to ensure the accuracy and efficiency of the machining process.

Guides You Might Need

CNC Machining Plastic Parts selection guide in 2025

Introduction: The Growing Role of CNC Machining Plastic Parts in 2025 In recent years, CNC machining plastic parts have become central to modern manufacturing. As industries push for lighter, more

How to choose right brass machined parts

Why Brass Machined Parts Matter in Modern Manufacturing The right brass machined parts make a very big difference to efficiency and quality of product at the end of today’s highly