Professional CNC Machining Service

High-Quality Milling, Turning & Advanced CNC Machining Solutions in One Stop

What Is CNC Machining?

CNC (Computer Numerical Control) Machining is a sophisticated, automated manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. It enables the high-precision production of components by removing material from a solid block (workpiece) using a variety of cutting tools.

The core principle involves translating a digital part design (CAD model) into numerical code (G-code), which instructs the CNC machine on precise movements, speeds, and tool paths. This method centralizes multiple machining operations, offering unparalleled automation, flexibility, and capability. Unlike manual machining, CNC ensures exceptional accuracy, repeatability, and the ability to produce complex geometries that would be inefficient or impossible to create manually, making it ideal for prototypes, custom one-off parts, and medium-to-high-volume production runs.

JST's Core CNC Machining Services

CNC Turning Service

JST is known for its excellent CNC turning services. We have an experienced and skilled team, as well as advanced processing equipment, to meet our customers’ needs for high-precision, complex-shaped parts. No matter the size of your project, we can provide individual solutions to meet your requirements.

We specialize in producing precision cylindrical parts. Our advanced CNC lathes rotate the workpiece while a stationary cutting tool removes material, expertly crafting features like diameters, tapers, grooves, and threads. Ideal for shafts, pins, bushings, and connectors, our turning service ensures excellent concentricity and surface finish.

CNC Milling Service

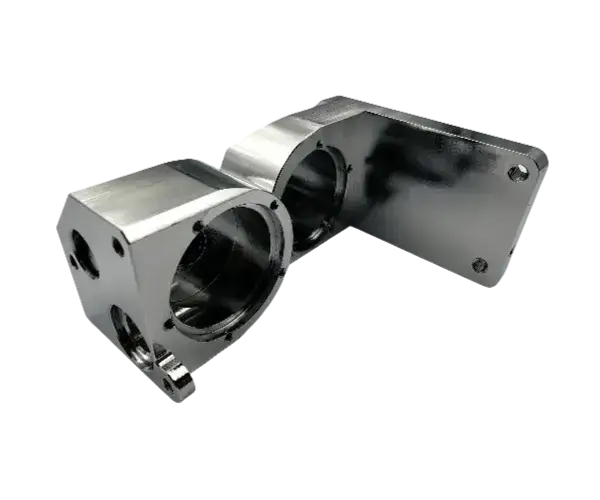

Our multi-axis CNC milling centers hold the workpiece stationary while rotating multi-point cutting tools sculpt the material. This service is perfect for creating complex 3D contours, pockets, slots, and precise holes in parts like enclosures, brackets, molds, and machine components, offering tremendous geometric freedom.

Precision Machining Service

JST uses advanced mechanical equipment and precision processing technology to meet customers’ strict requirements for part size, shape, and surface quality. Precision machining services usually use CNC machine tools (such as CNC milling machines, CNC lathes, CNC grinders, etc.) to process parts.

This encompasses our highest-tolerance work, often integrating multiple technologies like turning, milling, and grinding. Focused on ultra-tight tolerances and flawless surface finishes, it serves industries such as aerospace, medical, and optics, where absolute precision and part integrity are non-negotiable.

Advanced CNC Machining Processes

Turning Milling Compound Machining

This innovative process combines turning and milling operations on a single, advanced machine (mill-turn center). The workpiece can be rotated and milled in one setup, allowing for the complete machining of complex parts—like those with off-center holes or contoured surfaces—with outstanding accuracy and reduced lead times.

Precision CNC Turning

Utilizing high-precision Swiss-type or sliding headstock lathes, this process excels at machining small, intricate, and long-slender parts from bar stock in a single pass. It is exceptionally efficient for high-volume production of miniature components with diameters typically under 38mm, holding tolerances as tight as ±0.01mm.

Custom CNC Machining

This is the heart of our service: tailoring our entire process to your unique blueprint. From your drawings or 3D models, we engineer the optimal manufacturing strategy, selecting materials, machines, tools, and finishing processes to deliver a part that meets your exact specifications for form, fit, and function.

All CNC Maching Materials Parameter

| No. | Material | Description |

|---|---|---|

| 1 | 1018 Steel | General purpope 1018 steel is the most prominent of the carbon steels. The low carbon content makes this steel ductile and suitable for forming and welding. |

| 2 | Alloy Steel 4140 | Additional chromium makes this steel corrosion and fracture resistant. |

| 3 | Aluminum 2024-T3 | 2024 aluminum is used when a high strength-to-weight ratio is required, such as for gears, shafts and fasteners. It is nonmagnetic and heat treatable. |

| 4 | Aluminum 5052 | Corrosion resistant aluminum frequently used in sheet metal applications. |

| 5 | Aluminum 6061-T6 | Aluminum 6061 is easily machined and lightweight, perfect for prototypes, military and aerospace applications. |

| 6 | Aluminum 6063-T5 | Commonly used outdoors as architectural trim, railings, and door frames, 6063 aluminum has better machinability than 3003. It is nonmagnetic and heat treatable. |

| 7 | Aluminum 7075-T6 | Harder and higher strength aluminum alloy good for high-stress parts. |

| 8 | ASTM A36 | General purpose, hot rolled steel plate. Great for structural and industrial applications. |

| 9 | Brass C360 | A highly machinable brass. Great for prototyping gears, fittings, valves and screws. |

| 10 | Copper 101 | Commonly known as Oxygen-Free Copper, this alloy is great for electrical conductivity. |

| 11 | Stainless Stee 17-4 | A high strengh, corrosion resistant stainless alloy. Easily heat treatable. Typically used in medical equipment. |

| 12 | Stainless Steel 303 | A machinable, corrosion-resistant material. |

| 13 | Stainless Steel 304 | A machinable, corrosion-resistant material. |

| 14 | Stainless Steel 420 | Contains more carbon than stainless 410 to give it increased hardness and strength when heat treated. Offers mild corrosion resistance, high heat resistance, and improved strength. |

| 15 | Titanium Grade 2 | High strength, low weight, and high thermal conductivity. Ideal for applications in the aerospace and automotive industries. |

| 16 | Zinc Sheet Alloy 500 | Continuous-cast alloy. Has good electrical conductivity and is highly resistant to corrosion. This alloy is readily treatable for painting, plating and anodizing. |

| 17 | Acetal (White/Black) | Acetal resin with good moisture resistance, high wear-resistance, and low friction. |

| 18 | Acrylic (PMMA) | A clear glass-like plastic. Good wear and tear properties. Great for outdoor use. |

| 19 | Black ABS | High strength engineering plastic, used for many commercial products. |

| 20 | Nylon 6/6 | Offers increased mechanical strength, rigidity, good stability under heat and/or chemical resistance. |

| 21 | PEEK | Offering excellent tensile strength, PEEK is often used as a lightweight substitute for metal parts in high-temperature, high-stress applications. PEEK resists chemicals, wear and moisture. |

| 22 | Polycarbonate (PC) | A clear or colored, light-weight, glass-like plastic than can be machined. |

| 23 | PTFE (Teflon) | This material surpasses most plastics when it comes to chemical resistance and performance in extreme temperatures. It resists most solvents and is an excellent electrical insulator. |

Surface Finishes for CNC Maching Parts

As-Machined

Default surface from CNC; visible tool marks; roughness set by tool & parameters

Smooth

Abrasive tools/media remove top layer, reducing roughness & imperfections

Bead Blasting

Fine glass beads/media create smooth matte/satin finish; removes tool marks

Anodizing

Electrochemical thickening of natural Al oxide; clear or dyed; adds corrosion resistance

Polishing

Mechanical removal of material to create smooth/glossy or mirror-like surface

Powder Coating

Dry powder applied electrostatically & cured; durable, uniform, protective layer

Brushing

Abrasive belts/brushes produce uniform directional texture; satin/matte look

Electroplating

Blast with fine glass beads/media, removes tool marks & surface imperfections; mooth, matte, satin finish

Passivation

Chemical treatment for stainless/metals; removes free iron, enhances corrosion resistance

Heat Treating

Heating & cooling to alter hardness/strength/toughness; hardens outer layer

Electropolishing

Electrochemical removal smoothes & brightens; high-gloss, reflective; improves corrosion res.

Chromating

Chemical conversion coating on Al; provides corrosion resistance & paint primer

Sandblasting

Abrasive media (sand, Al₂O₃, etc.) cleans/textures; rougher than bead blasting

Tumbling

Vibratory finishing with abrasive media; polishes, deburrs, smooths complex/small parts

Laser Engraving

Laser beam etches permanent markings (logos, text, serial numbers); no overall finish change

Black Oxide

Chemical coating on steel yields black matte finish; moderate corrosion & glare reduction

Choose Our CNC Machining Parts

Advanced machining equipment and inspection equipment, we own 3/4/5 axis machining center (DMG) and the precision lathes (Star). In addition, we have two automatic CMM(Mitutoyo).

We have been ISO certified since 2010, and we are implementing 6S quality system. We have a professional engineering team and some experienced Q/C engineers.

We have over 100 customers from 15 different countries, 80% of our products were exported and we have won a good reputation.

Based on our excellent engineer team, we will constantly optimize the processing technology of parts and continuously reduce processing cost.

Application

The applications for precision CNC milling parts are nearly limitless. From aerospace and automotive to medical and consumer electronics, see how our expertise has been applied across industries—and imagine how we can help bring your design to life.

Medical Devices

Help Center

FAQ

Q1: What is the maximum part size you can machine?

A: Our machining envelope accommodates parts up to 1200mm x 1000mm. Specific capacities vary by machine; please consult with our engineers for your project’s dimensions.

Q2: What file formats should I provide for a quote?

A: We prefer 3D solid models (STEP, IGES, SLDPRT) along with 2D drawings (PDF, DWG) that detail critical dimensions, tolerances, materials, and post-processing requirements.

Q3: How do you ensure my parts meet quality specifications?

A: We implement a rigorous quality control process, including First Article Inspection (FAI), in-process checks, and final validation using precision equipment like CMMs. Full inspection reports are available.

Q4: Can you handle both low-volume and high-volume orders?

A: Absolutely. Our flexible manufacturing setup is designed for efficiency across all volumes, from one-off custom prototypes to long-term, high-volume production contracts.

Q5: What is your typical lead time?

A: Lead times depend on part complexity, quantity, and current scheduling. Prototypes can often be shipped in 1-2 weeks, while production timelines will be confirmed during quoting. We prioritize clear communication on deadlines.

Guides You Might Need

CNC Milling Services: Design To Delivery Guide

Getting parts made sounds simple enough. Send a drawing, receive finished components. But anyone who’s actually gone through the process knows there’s considerably more happening between those two points. Understanding

How To Choose Surface Finishes For CNC Milled Parts

The machining is done. Parts come off the machine looking decent, maybe even pretty good. But here’s the thing — that as-machined surface isn’t always the final answer. Sometimes it’s