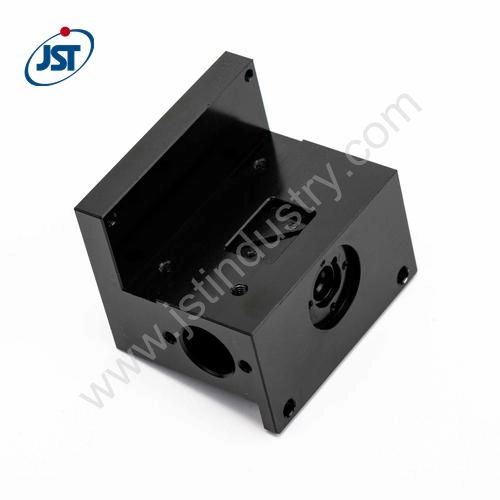

Precision Custom Steel Machining Lathe Parts

Introduction to Precision Custom Steel Machining Lathe Parts

The quality and efficiency of precision lathe parts have gained paramount importance in today’s manufacturing industry because it directly influences the competitive capabilities of the final product. Our company offers precision custom steel machining lathe parts conveyed with efficient and precise processing solutions. Equipped with advanced CNC machining technology as well as an experienced engineering team, we, as a lathe parts manufacturer, can meet diverse industrial requirements. This enables us to offer personalized solutions for the parts needed in a specific application.

Features

Our precision customized steel machined turning parts have the following key features:

1. High-precision machining: Advanced CNC machining technology is adopted to ensure that the machining accuracy error of each part is controlled at micron level, which meets strict industry standards.

2. High-quality material: high-strength steel is selected, which has excellent wear resistance and corrosion resistance and can work stably in various harsh environments.

3. Flexible design: It can be customized according to the specific needs of customers, providing parts of various shapes and sizes to meet the personalized design needs of customers.

4. Various surface treatments: We, as a manufacturer, provide various surface treatment options, including spraying, galvanizing and phosphating, which can further enhance the durability and aesthetics of products.

Advantages

Customers will enjoy the following advantages by choosing our precision custom steel machining lathe parts:

Fast delivery: With efficient processing flow and strict production management, we can complete the delivery of orders in a short time and maintain the stability of delivery even in the peak period.

High-cost performance: By optimizing the production process, the production cost is reduced, so that customers can obtain high-quality products at a more reasonable price.

Comprehensive service: We provide one-stop service from design, processing to later quality inspection to ensure that every link meets the high standards of customers.

Application

Our precision turning parts are widely used in many industries, including but not limited to:

Automobile industry: Used for key components such as engines and transmissions to enhance the performance and safety of automobiles.

Aerospace: used for aircraft parts, fuel systems, etc., to ensure reliability in harsh environments.

Mechanical manufacturing: used for precision parts of various mechanical equipment and tools to improve the operating efficiency of equipment.

Electronics and electric power: used in electronic equipment, instruments and meters, etc., to meet the requirements of high precision.

1. Do you support small batch customization?

Yes, we can challenge small and large orders and flexibly respond to customer needs.

2. What is the usual delivery time?

In general, the delivery time is 7 to 15 working days, depending on the specific order quantity and complexity.

3. Have your products passed the quality inspection?

We strictly control every production link, and all products undergo comprehensive quality inspection before shipment to ensure that they meet customer requirements.

“The quality of JST Industry’s products is very good, which meets our high standard requirements, and the after-sales service is also very caring.”

“The whole process from ordering to delivery is very smooth, and I look forward to cooperating with your company again!”