Custom Precision CNC Milling Brass Spare Parts

Custom Precision CNC Milling Brass Spare Parts Collection

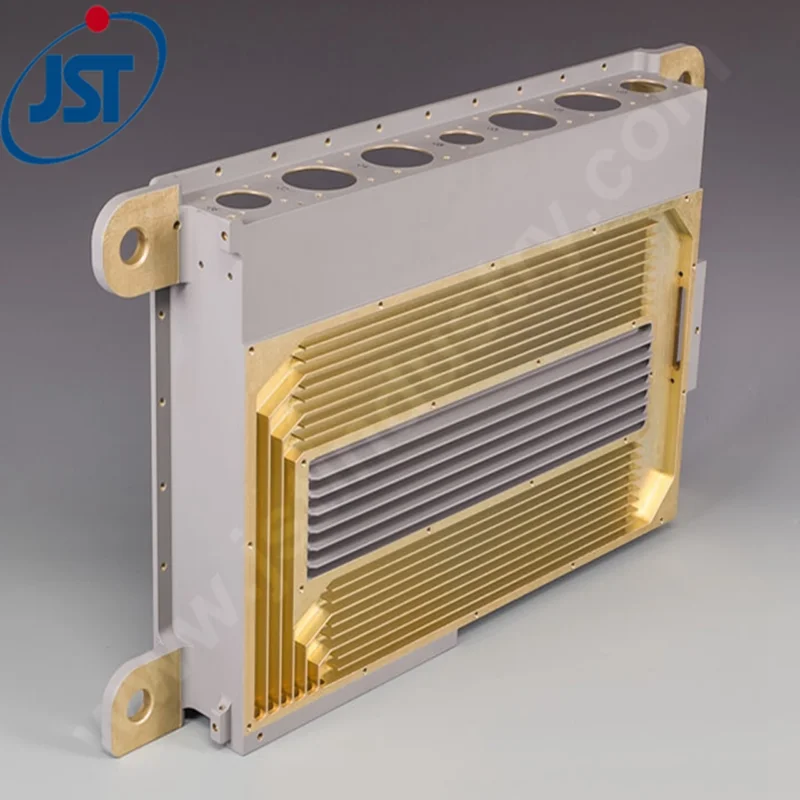

JST specializes in providing custom precision CNC milling brass spare parts, especially for industrial equipment. We use 4-axis machining centers to manufacture each part to ensure extremely high machining accuracy and complexity. The material used is high-quality copper, and the surface treatment adopts a powder spraying process, which greatly improves the corrosion resistance and wear resistance of the parts. With more than 10 years of industry experience, we have carried out 100% quality inspection on each key dimension to ensure that each part delivered to customers meets high standards. If you have any questions about our custom products, please feel free to send us a file for a quote. At the same time, we can also provide you with sample production services to ensure that the product meets your specific needs.

Product Features:

1. High precision processing: Via the technology of 4-axis CNC processing, it is guaranteed that this product has high precision in complex geometry and delicate features to meet various industries’ application needs.

2. Selection of materials: The mechanical properties of the brass material used are excellent; the strength is good, while resistance to corrosion and conductivity have been guaranteed, ensuring its use stably for a long time under various environmental conditions.

3. Perfect surface treatment: Powder coating provides an additional protective layer to custom precision CNC milling brass spare parts and enhances their wear and corrosion resistance; it also increases the quality of appearance.

4. 100% critical dimension inspection: We carry out an overall inspection on critical dimensions for each custom precision CNC milling brass spare part, ensuring the integrality and accuracy of a part in order to lower customers’ load and risk caused by the latter inspection.

5. Rapid prototyping: With a customer-first attitude, we provide rapid prototyping services to help customers obtain the required samples for testing and verification in the early stages of development.

Product Value:

Choosing JST’s custom precision CNC milling brass spare parts will bring you many unique values:

– Improve product reliability: Use high-quality materials and precision processing technology to provide your equipment with high-reliability parts to ensure stable operation of the equipment and reduce the failure rate.

– Improve performance and efficiency: High-performance custom precision CNC milling brass spare parts can significantly improve the working efficiency and production capacity of industrial equipment to meet the growing needs of the market.

– Reduce operating costs: Due to the durability and wear resistance of the custom precision CNC milling brass spare part, the additional expenses caused by maintenance or replacement of parts are reduced, thereby reducing long-term operating costs.

Applications:

JST’s custom precision CNC milling brass spare parts are suitable for a wide range of industries and fields, including:

– Mechanical manufacturing: Provide key custom precision CNC milling brass spare parts for the operation of various industrial machinery to ensure its normal operation.

– Electronic accessories: Can provide high-performance contact terminals and connection parts for the construction of electronic products and equipment.

– Automation equipment: Used in some structures of industrial automation equipment to improve its functionality and stability.

– Automotive parts: As an important raw material in automobile production, custom precision CNC milling brass spare parts provides key accessories to ensure the function and safety of the car.

– Aerospace: High-precision components used in the aerospace industry to meet strict quality standards and performance requirements.

——

The brass material used in JST’s custom precision CNC milling brass spare part has excellent mechanical properties, good strength, corrosion resistance, and conductivity. If you need further information or a quote, please feel free to contact us.

1. What is our minimum order quantity?

For custom precision CNC milling brass spare parts, the minimum order quantity is 1,000 pieces to ensure the economy and efficiency of production.

2. How long is the delivery time?

Our delivery time is usually 30 days, but the specific delivery period may be adjusted depending on the order quantity and production plan.

3. How to make samples?

Customers can provide documents and drawings as needed, and we will make prototypes according to the requirements. The cost and delivery time will depend on the specific circumstances of the project.

4. Does the custom precision CNC milling brass spare part provide a warranty?

Yes, all products are subject to strict quality control, and we promise to provide corresponding warranty services to ensure product quality.

5. How to get a quote?

Please contact us by email or phone, provide your specific requirements and drawings, and we will provide you with detailed quotation information as soon as possible.

“We are very happy to cooperate with JST. We are very satisfied with their processing accuracy and service quality.” – An engineer from a machinery manufacturing company.

“The custom precision CNC milling brass spare parts perfectly meet our design requirements. The JST team responded quickly, which made our project progress more smoothly.” – A project manager of an automation equipment company.

“Using JST’s custom precision CNC milling brass spare part ensures that our products can remain competitive in the fierce market.” – Purchasing director of a well-known automotive parts supplier.