- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-01-07 Origin: Site

Today's fast-moving environment for manufacturing brings critical success in both project fruition and overall cost control directly into a developer's hands regarding picking the proper CNC machining service. Otherwise known as Computer Numerical Control, CNC works toward services that deliver precision, efficiency, and scalability to production. Whether you're involved in casting and forging, metal fabrication, or plastic injection molding, making informed decisions about CNC machining services is critical.

However, the process of selecting the right service provider can be fraught with challenges. With numerous options available, how do you ensure that you’re making the best choice? This article aims to provide you with a comprehensive guide on how to choose a CNC machining service supplier that aligns with your project's specific needs.

Before diving into the selection process, it is essential to understand the various types of CNC machining services that are commonly available. For instance, consider JST's offerings which include:

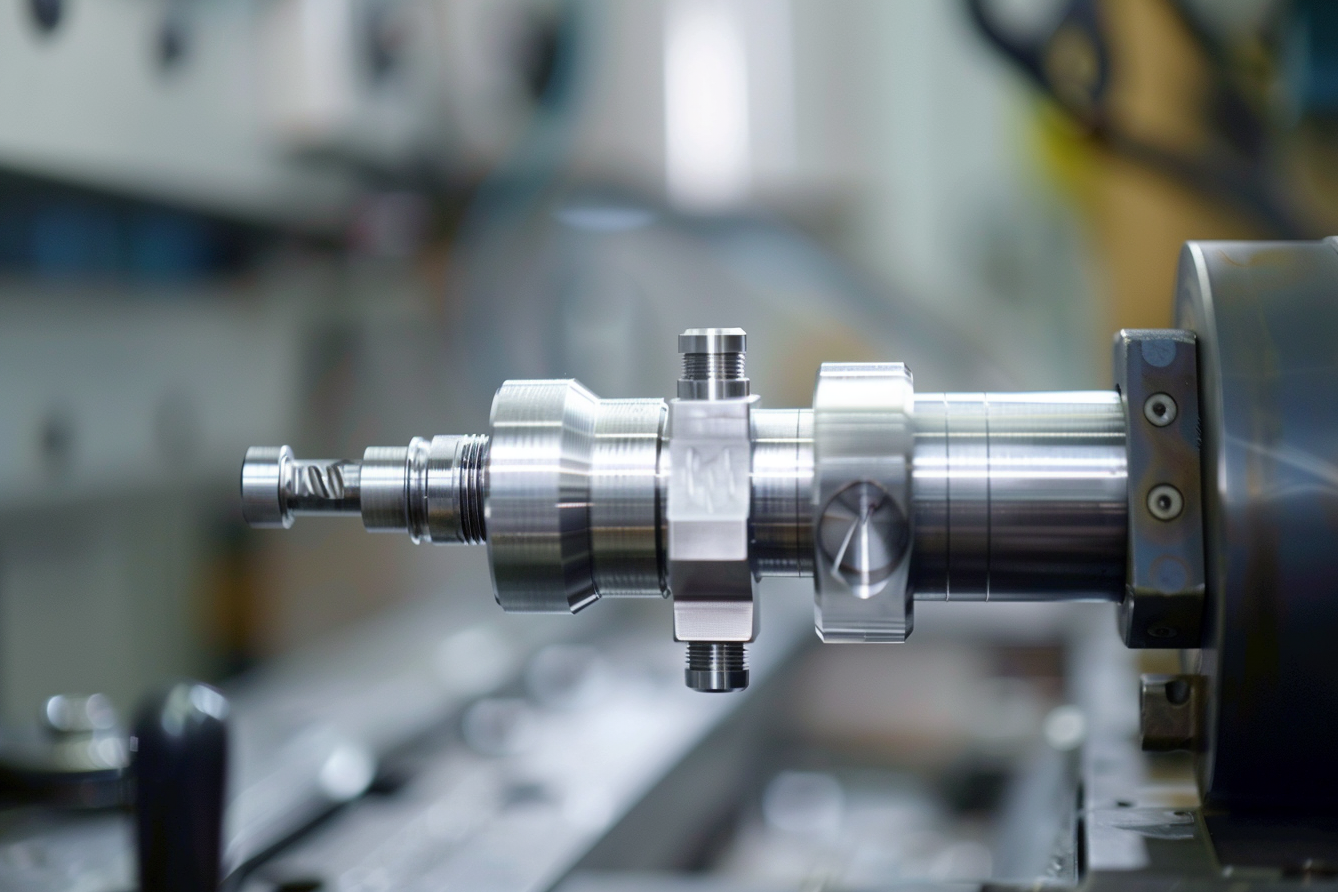

CNC turning service is a fundamental aspect of CNC machining where the workpiece is rotated against a stationary cutting tool. CNC precision turning is the only choice for precision component manufacturing, particularly for cylindrical parts that demand high accuracy.

CNC milling parts are revolutionary in production. With multi-axis tools, CNC milling is able to make complex geometries and intricate designs. This service is important in projects that require detailed modification and adaptation.

Precision machining service focuses on delivering precision machining parts as the backbone of efficient industrial equipment. What this means for the machined parts is that they will have close tolerances and tight specifications, which are important to high-performance applications.

Understanding these key service types will give a good grounding for you to identify your particular needs and the competencies you may require from your selected CNC machining service provider.

Based on the overview above of CNC machining services available, the next step is to define your specific needs. Many factors will be considered:

What is the material to be used? Different materials can be used for CNC machining services, such as metals, plastics, and composites. Ensure that the service provider can machine the type of material you need.

Components manufactured should be looked into in regard to complexity. Whether they will be just plain geometric shapes or highly engineered products would go a long way in telling one the type of CNC machining services they could need.

Is your requirement for low-volume or high-volume runs? A number of CNC machining services are oriented towards large lots, while others can respond to the needs of low batches. Knowing your quantity requirements will help narrow down your options.

Determine your budget and be prepared for the range of costs involved with the CNC machining services. The pricing of different services can change based on the complexity, material, and volume of production.

Having now defined your requirements, it's time to source the CNC machining service suppliers. Here is how to go about this process:

The reputation of the provider may play a huge role in the success of your project. Look for providers with excellent reviews on the web, testimonials, and a healthy portfolio that indicates what they are capable of doing.

Ensure that the companies you research can work with your specific needs. For example, if there is a need for complicated shapes, it should be ascertained that they offer CNC milling services and understand the peculiarities of that process.

If possible, check whether the potential suppliers adhere to standards such as industry-specific certifications. Those accreditations represent an assurance of quality and signify that a machined component follows best practices.

Think of the geographical location of a service provider. In most instances, a locally available supplier would come in handy for various logistic advantages like quicker turn-around times and low shipment costs.

Expertise and experience are probably two of the most important ingredients in a successful partnership with any CNC machining service. Look out for:

The more years a company has been in business, the more reliable it would be because, over time, it would have refined its processes.

Request samples of past projects, ensuring the workmanship would live up to your expectations. It may well give one good insight into the capability of a particular facility.

Confirm the level of qualification and training of staff to operate CNC machinery. Higher-skilled personnel are better suited to accomplish more challenging tasks at the highest levels.

Pay a visit to the facilities of the potential service providers before making your final decision about where to get the CNC machining services. This due diligence may be very important in providing key information:

First to observe is the state and type of machines and equipment the provider has at their facility. Well-maintained and modern equipment is commonly a good indicator of a company's commitment to high standards in their output. Check the signs that it is regularly serviced, such as cleanliness and proper calibration. Modern machinery, with the latest technology, is more likely to provide precision, efficiency, and consistency in production. Also, ask what kinds of machines they have, as this can offer more flexibility regarding different materials and intricate designs. A supplier with a broad range of equipment can fulfill a wider variety of manufacturing requirements.

Knowing the workflow and production processes of the service provider will give valuable insight into how efficient and effective they are. Make sure to ask specific questions about their production capabilities, such as how much volume they can handle, what types of materials they specialize in, and how long it generally takes them to turn around a product. A good production flow should ensure reduced downtime, reduce waste, and deliver the product on time. Also, request to know their quality assurance measures. There is a high need for good quality assurance in this production cycle.

For parts review parts from the supplier could be ordered when and if possible. This will afford you the luxury of assessing delivery in terms of quality and precision, which is, of course, your main concern with the parts. Go through the sample parts for defects, irregularities, and conformity to your specifications. Pay special attention to finish, dimensional accuracy, and overall workmanship. Ask, if possible, for similar complexity and material samples to your project so that a better view of their skill level can be gained. Evaluating sample parts is one of the most critical links to ensuring that the provider can deliver the standard to which you strive in quality and precision.

Focus in these areas provides insight into the provider's capability and commitment to quality. It will afford a detailed perspective to enhance your decision-making regarding which service provider will most appropriately serve the needs and dreams of your project.

Once you have made up your mind regarding the CNC machining service provider that best goes with your project requirements and vision, you will want to finally decide how to negotiate the contract. This is an extremely important stage that sets the ground for a successful partnership. Below are some of the key focus areas in negotiation:

The contract should include all relevant details articulately. It contains solid timelines for each milestone and the end product itself, clear descriptions of what needs to be delivered, payment terms spelling out the schedule, amounts, and any conditions tied to payments, as well as strict quality standards to which a service provider has to adhere. You will limit the possibility of not experiencing misunderstandings or disputes in the future by having such elements inked with due care. Make sure that the scope of work, responsibilities, and expectations are well understood by both parties.

If your project involves proprietary designs, technologies, or sensitive ideas, the contract should be filled with airtight provisions for the protection of your intellectual property. These could include confidentiality clauses, ownership rights, limitations on use, and clear rules determining how, when, and under what circumstances the service provider can use or disclose any IP-related information. In this way, you will have considerable background regarding your IP, securing your competitive advantage and providing a substantial degree of protection from probable legal challenges.

Projects change either due to new information that becomes available or because requirements change based on market dynamics or internal decisions. It is hence important to discuss and incorporate flexibility provisions into the contract. This may include clauses that would allow adjustments to timelines, deliverables, or even the scope of work based on mutually agreed criteria. Flexibility provisions should be used to stipulate how changes should be negotiated; additional costs or delays can be accounted for. Such provisions make a contract more flexible so that when challenges that cannot be predicted come up, the parties have the opportunity to be effective in adapting to change within a collaborative atmosphere.

These are perhaps the most basic yet very important pointers that will form the foundation of an effective partnership with your CNC machining manufacturers to meet on the smooth path toward success. In this regard, your risks are minimized with respect to project success and establishing a long-term relationship.

Working with a CNC machining service provider requires effective communication to ensure project success and the highest quality standards. Here are some points of view to foster a mutually beneficial partnership.

Ensure that at every step in the process of production, there will be regular updates. In that way, you would be updated on everything from the design review of the initial design to the final quality inspection. The right information at the right time is vital to proactively respond to any potential problems or issues before they get out of control and dent deadlines or budgets. Besides, regular updates provide for trust and openness, hence reinforcing the teamwork nature of your partnership.

There must be a methodical way of providing feedback to ensure that there is continued improvement. This is meant not only as active input on any quality factor of the machined part but also to highlight other facets of the service that need attention. In a free-flowing discussion, you are able to discuss areas of further improvement for positive outcomes and a strong working relationship. Make sure that the CNC machining service provider solicits your input regularly and acts upon it immediately.

It should be agreed upon mutually to set specific, measurable assessments that can express the advancement of the project as well as the quality of work produced. Some examples would be delivery times, defect rates, work utilization efficiencies, and customer satisfaction scores. In this way, both sides know they have to maintain expectations from the day of signing. A regular review of performance on metrics would allow both partners to see whatever trends, areas for improvement, or achievements existed. This also aligns incentives such that your CNC machining service provider is constantly incentivized to provide the best level of work.

Deploying these communication strategies will allow you to establish a good collaborative relationship with your CNC machining service provider such that your project succeeds, quality is maintained, and continuous improvement is made in your manufacturing processes.

Choosing a suitable CNC machining service to achieve your manufacturing goals affects the success of the project and cost control. CNC milling parts is a revolution in production, offering unparalleled precision and efficiency that can transform your manufacturing processes. By understanding the various services available, defining your specific needs, and conducting thorough research, you can identify the CNC machining service providers that best align with your objectives.

The key to project success and cost control is not just having access to advanced CNC technology, but selecting the right CNC machining service that can fully harness its potential. In cooperation with well-skilled and experienced service providers, one's production is maximized in capability, maintaining quality, and competitiveness. Whether it is any precision machining of parts for complex assemblies or volume for consumer products, the perfect CNC machining service will be greatly instrumental in securing the attainment of your manufacturing needs. Unlock the full potential of CNC technology and collaborate with the best service providers to perfect your manufacturing processes, increase efficiency, and take your business into a prosperous future.

The Application of CNC Machining Parts in the Production of New Energy Vehicle Parts

Revolutionize Your Logistics with Intelligent Sorting Machines and Custom CNC Machining Parts

Your Trusted Partner in Custom CNC Machining - China's Premier Mechanical Parts Manufacturer

The Widely Application of CNC Machining Aluminum Parts In The Field of New Energy Auto