JST Industry

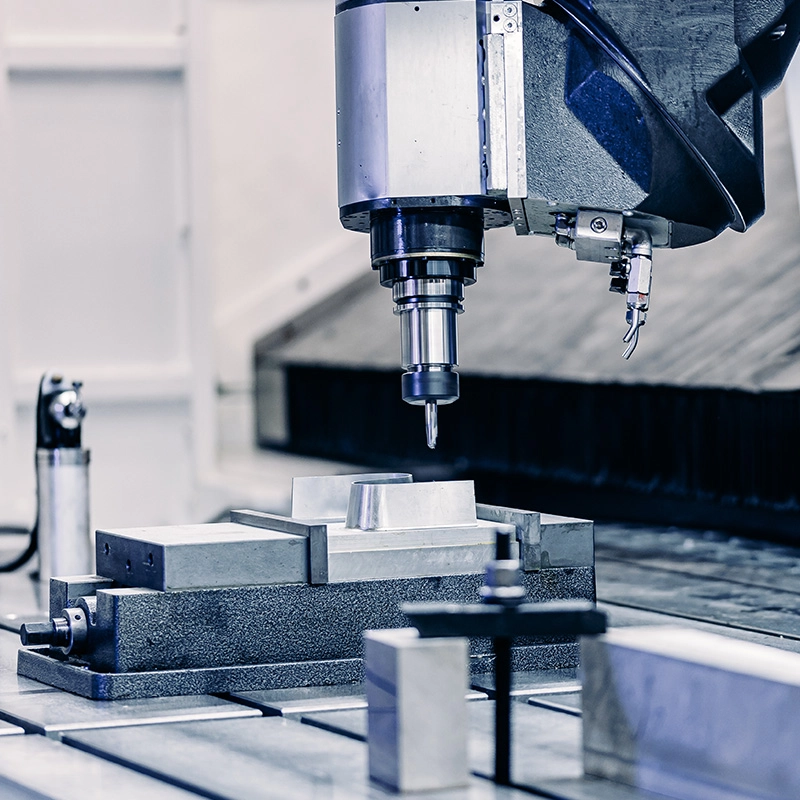

Provides professional CNC aluminum machining services

Advantages of Aluminum Machining

Aluminum alloys occupy a central place in JST Industry’s CNC machining services and are used in a wide range of industries due to their manifold advantages.

Here are some of the significant advantages of machining aluminum alloys:

Low Density

The lightweight nature of aluminum alloys is critical for applications that require weight reduction, such as in the automotive and aerospace sectors.

Good Mechanical Properties

Aluminum alloys exhibit high strength and hardness while maintaining the material’s ductility, making machining more precise and versatile.

High Thermal and Electrical Conductivity

These properties make aluminum alloys ideal for the manufacture of radiators, heat exchangers and electrical components.

Corrosion Resistance

This property of aluminum alloys makes them especially popular in medical and safety equipment manufacturing, where materials must be resistant to body fluids and cleaning agents.

Excellent Machinability

Aluminum alloys have a low work-hardening rate, which means it can be subjected to complex CNC operations without sacrificing dimensional accuracy.

Aluminum Machining Properties and Applications

JST Industry offers CNC machining services for aluminum alloys with a wide range of aluminum alloy material options for the specific needs of different industries.

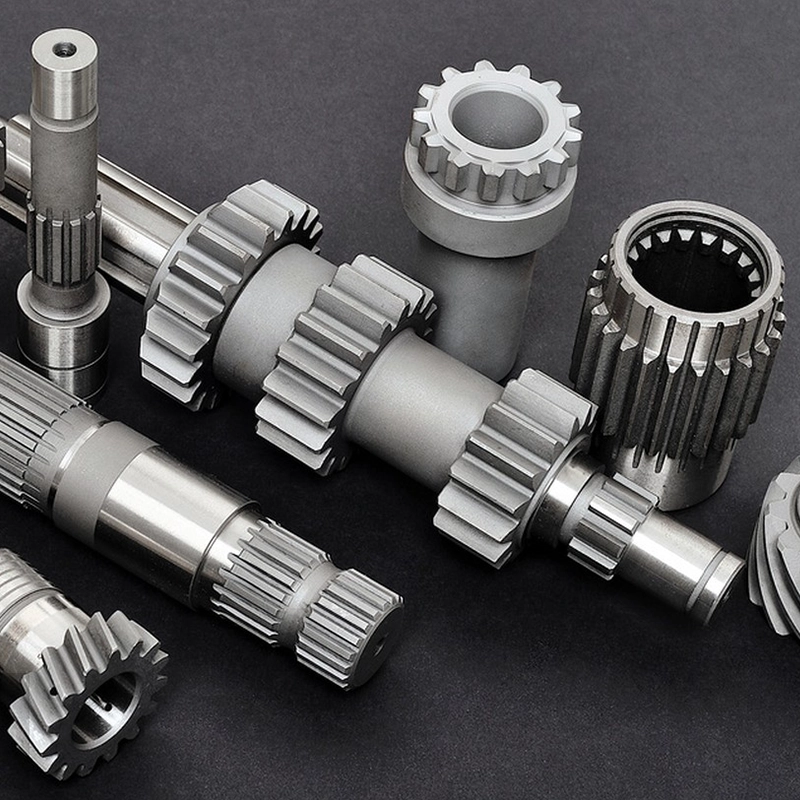

High Strength

Alloys such as 7075-T651 are suitable for manufacturing aerospace components and automotive safety parts that are subjected to heavy loads.

Hardness

The hardness of aluminum alloys makes them the material of choice for precision mechanical parts and structural components of electronic equipment.

Heat Resistance

For industrial equipment and automotive components that need to operate reliably in high-temperature environments.

Corrosion Resistance

CNC Aluminum Machining Parts

Aluminum Surface Treatments and Finishing

JST Industry offers a variety of surface treatment options after CNC machining of aluminum alloys to enhance the appearance, durability and functionality of the product. Below are a few common surface treatments:

Anodizing: This is an electrochemical process used to increase the corrosion and abrasion resistance of aluminum alloys while offering a wide variety of color options.

Type I: Thin layer anodizing, commonly used for welded parts and assemblies, and as a primer before painting.

Type II: Sulphuric acid anodized, provides a harder surface for parts requiring high durability, such as motorcycle parts and hydraulic valves.

Type III: Hard anodized, the thickest and hardest anodized finish, for parts in automotive, aerospace, heavy industry and military equipment.

Other Surface Finishes: In addition to anodizing, JST Industry also offers surface finishes such as sandblasting, polishing, and plating to meet the needs of different customers.

Aluminum Machining Cases and Feedback

Medical Device Manufacturer, California, USA

“Working with JST Industry was key to the success of our project. Their precision machining techniques on aluminum alloys have enabled us to achieve an unprecedented level of precision in our medical device components. Their professional service and attention to detail ensures the quality and performance of our products.”

Aerospace Component Supplier, Munich, Germany

“In the aerospace industry, the weight and strength of each component is critical.JST Industry’s aluminum CNC machining services not only met our lightweighting needs, but also ensured the durability and reliability of the components. Their quick response and flexible production capabilities enable us to respond quickly to market changes.”

Automotive Parts Manufacturer, Shanghai, China

“CNC machining of aluminum alloys has been the solution we were looking for to improve vehicle performance and reduce fuel consumption. the high quality of machining services provided by JST Industry, coupled with their expertise in surface treatments such as anodizing, has enabled us to produce automotive parts that are both aesthetically pleasing and durable.”

Consumer Electronics Company, Shenzhen, China

“Our product designs require lightweight yet strong materials. jst industry’s aluminum alloy machining services provided the perfect solution. Their in-depth knowledge of aluminum alloy materials and superb mastery of machining techniques make our products stand out in the market.”

FAQs

Q: I am designing a new product that requires CNC machining to create a prototype and final product. How do I select the most suitable material for CNC machining for my project?

A: At JST Industry, we understand that choosing the right CNC machining material is critical to product design. You should first consider the scenario in which your product will be used, including the required mechanical properties, temperature resistance, corrosion resistance, and cost-effectiveness. We offer a wide range of material options including, but not limited to, aluminum alloys, stainless steel, brass, various alloys, and many plastics. Our team of experts can assist you by selecting the most appropriate material for your specific needs and provide expert design optimization advice to ensure an efficient and cost-effective CNC machining process.

Q: I would like to know how the selection of different materials in CNC machining process affects the final machining cost?

At JST Industry, we recognize that material selection has a significant impact on CNC machining costs. The type of material, difficulty of machining, and market availability all affect its price. For example, steel is widely used due to its lower cost, while titanium alloys and certain advanced alloys are more expensive due to their higher material cost and machining difficulty. In addition, the machinability of the material also affects the cost, e.g. aluminum alloys are usually less expensive due to their ease of machining. Our quoting system takes all of these factors into account to ensure you get the most accurate cost estimate.

Q: What are some design practices that can help me reduce machining costs when designing CNC machined parts?

Q: I have stringent requirements for accuracy in my products, what tolerances can be achieved with CNC machining and how does this affect the quality of the final product?

A: At JST Industry, our CNC machining services are capable of meeting extremely high tolerances, often to ±0.01mm, thanks to our advanced machining equipment and strict quality control processes. This high-precision machining capability ensures consistency and reliability of parts, which is especially important for assemblies that require high-precision fit. Our quality assurance system includes multiple inspections and calibrations to ensure that each part conforms to the customer’s design drawings and tolerances, thus guaranteeing the quality of the final product.