Aerospace CNC Machining & Aircraft Parts CNC Machining

Application Scenarios

Aerospace CNC Machining & Aircraft Parts CNC Machining

CNC machining technology plays a central role in the manufacture of aerospace components, used to produce, for example, turbine parts, combustion chamber assemblies, engine casings, and more. These components are typically made of high-temperature and corrosion-resistant nickel- and titanium-based alloys that require extremely high precision and surface finish.

Spacecraft Component Machining

In spacecraft manufacturing, CNC machining is used to produce structural components, satellite assemblies, rocket motor parts, and more. These components often require lightweight, high-strength materials such as aluminum alloys and composites.

Avionics Machining

CNC machining technology is used to manufacture precision components in avionics, including circuit boards, connectors, sensors, and more. These components are critical to an aircraft’s navigation, communication and monitoring systems.

Aviation Interior Machining

CNC machining is also used in the production of aviation interior components such as seat structures, lockers, and passenger service assemblies. These components need to meet comfort, durability, and lightweight requirements.

Technical Advantages

Realizing High-Precision Manufacturing

CNC machining technology is capable of achieving micron-level precision to meet the stringent size and shape requirements of aerospace components, ensuring consistency and reliability.

Wide Range of Material Adaptability

CNC machining can handle a wide range of materials from lightweight alloys to high-strength steels, accommodating the diverse material performance needs of the aerospace industry.

Rapid Prototyping

CNC machining technology can quickly transform from design drawings to physical prototypes, accelerating product development cycles and making design iterations more efficient.

Ability To Machine Complex Parts

CNC machining technology is good at machining parts with complex shapes and fine structures, such as impellers and blades of aero-engines.

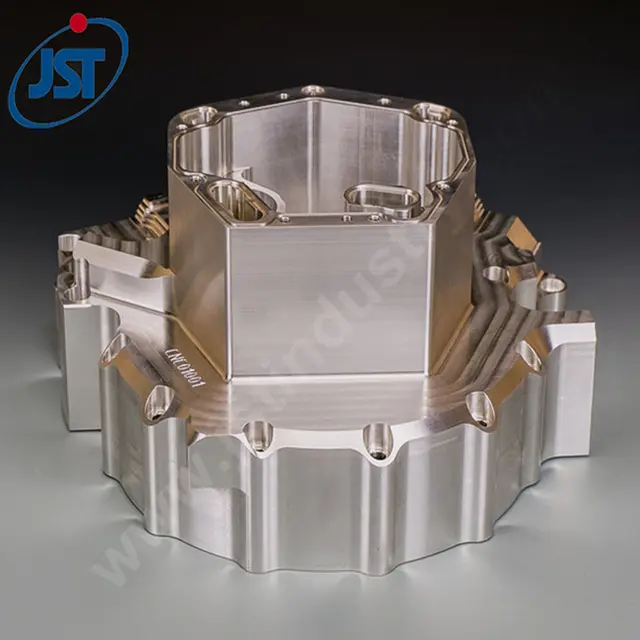

Case Display

Industry Trends

Lightweight Design

With the improvement of environmental requirements and the pursuit of fuel efficiency, lightweight design has become a trend in the aerospace industry, and CNC machining technology plays an important role in the application of lightweight materials.

Multi-material Integration

Aerospace components are more and more inclined to adopt multi-material integrated design, CNC machining technology can realize the precise processing and integration of different materials.

Automation and Intelligence

Automated and intelligent production lines are gradually replacing traditional manufacturing methods. The combination of CNC machining technology and robotics improves production efficiency and machining accuracy.

FAQs

How accurate is CNC machining in the aerospace industry ?

CNC machining technology is capable of extremely high machining precision, often down to the micron level, to meet the aerospace industry’s stringent requirements for component accuracy.

What materials are commonly used for CNC machining ?

Commonly used CNC machining materials include aluminum alloys, titanium alloys, stainless steel, high-temperature alloys, composites, and high-performance plastics.

How do I choose the right CNC machining service provider ?

When choosing the right CNC machining service provider, you should consider its technical capability, quality management system, material handling capability and response time. Choosing a provider with ISO certification and a good industry reputation will ensure product quality and delivery time.

What are the applications of CNC machining in the aerospace industry ?

CNC machining applications in the aerospace industry include the manufacture of aero-engine components, spacecraft structural components, avionics, and interior components.