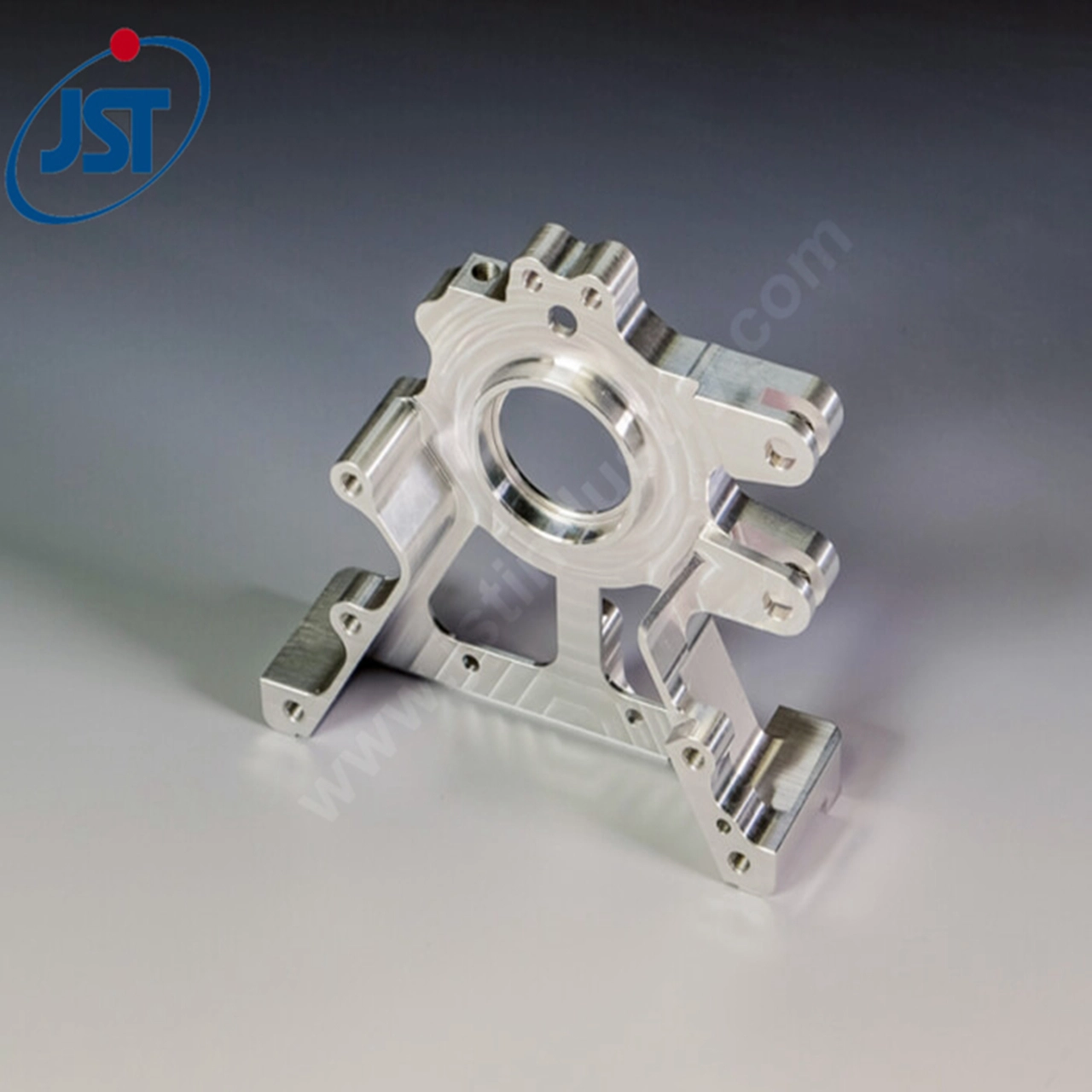

Look around. From the sleek chassis of your smartphone to critical components deep inside an aircraft’s wing, aluminum CNC machining parts are critical in the modern world. But how do these intricate, surprisingly durable, and lightweight components come to be? The answer, more often than not, lies in a powerful manufacturing duo: the versatile material of aluminum and the high-precision process of CNC machining. This technology has quietly become a cornerstone of modern industry, enabling the creation of incredibly complex parts with an accuracy and efficiency that was once unthinkable.

So, What Exactly is Aluminum CNC Machining?

First, let’s break down the name. CNC stands for Computer Numerical Control, which is really just a fancy way of saying it’s an automated manufacturing process where pre-programmed software tells factory tools exactly what to do. Instead of a machinist manually guiding a cutting tool, a computer follows a digital blueprint with a level of precision that’s frankly superhuman.

CNC machining is what’s known as a subtractive process. This means it starts with a solid block of material (in this case, aluminum) and strategically carves away the excess to reveal the final part. It’s the opposite of something like 3D printing, which adds material layer by layer. By starting with a solid block, the finished component keeps all the inherent strength and structural integrity of the raw material—a huge advantage.

Why Aluminum is Such a Go-To for CNC Machining

1. An Unbeatable Strength-to-Weight Ratio

Everyone knows aluminum is light—about a third of the weight of steel, in fact. What’s surprising is that when mixed with other elements, certain aluminum alloys can achieve strengths that rival steel. This combination is invaluable in industries like aerospace and automotive, where cutting weight directly translates to better performance and fuel efficiency.

2. It's Just Easy to Machine

In the manufacturing world, “machinability” is a big deal. It’s all about how easily a material can be cut, and aluminum is a dream to work with. Being softer than metals like steel or titanium, it can be machined up to three or four times faster. This speed has real-world benefits: shorter production times, lower energy bills, and less wear and tear on the cutting tools. All of this makes the whole process more affordable.

3. It Resists Corrosion Naturally

When you expose aluminum to the air, something interesting happens. It instantly forms a thin, tough layer of aluminum oxide on its surface. This natural shield protects the metal from rust and other environmental damage, making it incredibly durable for parts used outdoors or in wet conditions.

4. Conducts Heat and Electricity Well

Aluminum is a fantastic conductor of both heat and electricity, much better than steel. This is why it’s the default material for things like heat sinks in electronics (they pull heat away from sensitive processors) and all sorts of electrical connectors.

5. It's Highly Recyclable

From an environmental standpoint, aluminum is a winner. It’s 100% recyclable without losing any of its properties. Plus, recycling it is incredibly efficient, using just a tiny fraction of the energy needed to create new aluminum from scratch.

The Journey: From a Digital File to a Physical Part

The Design Phase (CAD/CAM): It all starts on a computer with a 2D or 3D model of the part, created in CAD (Computer-Aided Design) software. This is the master blueprint. That file is then loaded into CAM (Computer-Aided Manufacturing) software, which acts as the strategist, planning out the exact path the cutting tools will take and figuring out the best speeds for the job.

The Setup: A solid block of a specific aluminum alloy is clamped down securely inside the CNC machine. Any wobble or vibration here would ruin the final part. The required cutting tools—drills, mills, and the like—are loaded into the machine’s turret, ready to go.

The Machining: With the press of a button, the machine’s computer takes over, executing the programmed code. The cutting tools get to work, shaping the aluminum with incredible speed and precision. The main operations usually include:

CNC Milling: A spinning tool moves around a stationary block of aluminum to carve out material. This is how you get flat surfaces, pockets, and complex shapes.

CNC Turning: The block of aluminum spins at high speed while a stationary tool cuts into it. This is the go-to method for creating cylindrical parts like shafts and pins.

Drilling and Tapping: Just like it sounds, these operations create and thread holes for screws and bolts.

A Few Popular Aluminum Alloys You'll See

The “aluminum” used in aluminum CNC machining part is almost never pure; it’s an alloy, mixed with other elements to get just the right properties. While there are hundreds of options, a few tend to show up over and over again.

6061-T6: Think of this as the Swiss Army knife of aluminum alloys. It’s the go-to for just about everything because it offers a fantastic balance of strength, machinability, and corrosion resistance. You’ll find it in everything from bicycle frames to electronic casings.

7075-T6: Then you have the heavy hitter. Often called “aircraft-grade” aluminum, 7075 is one of the strongest alloys out there, with a strength-to-weight ratio that can compete with some steels. It’s the top choice for high-stress parts in aerospace, defense, and high-performance sports gear.

5052-H32: This alloy is famous for one thing above all else: its incredible resistance to corrosion, especially from saltwater. This makes it the undisputed champion for marine applications—think boat hardware, fuel tanks, and anything else that has to survive in a harsh, wet environment.

In Conclusion

At the end of the day, the partnership between aluminum’s fantastic material properties and the incredible precision of CNC machining is one of those perfect matches in manufacturing. This combination allows for the creation of parts that aren’t just complex and accurate but are also lightweight, strong, and built to last. Whether it’s for a high-performance race car or the phone in your pocket, aluminum CNC machined parts deliver a blend of performance, versatility, and value that’s tough to beat.

If you want to learn more about choosing the right aluminum CNC machined parts, check out our article How to Choose the Right Aluminum CNC Machining Parts? for detailed guidance.