Gravity Industrial Aluminum Sand Casting

Gravity Industrial Aluminum Sand Casting Collection

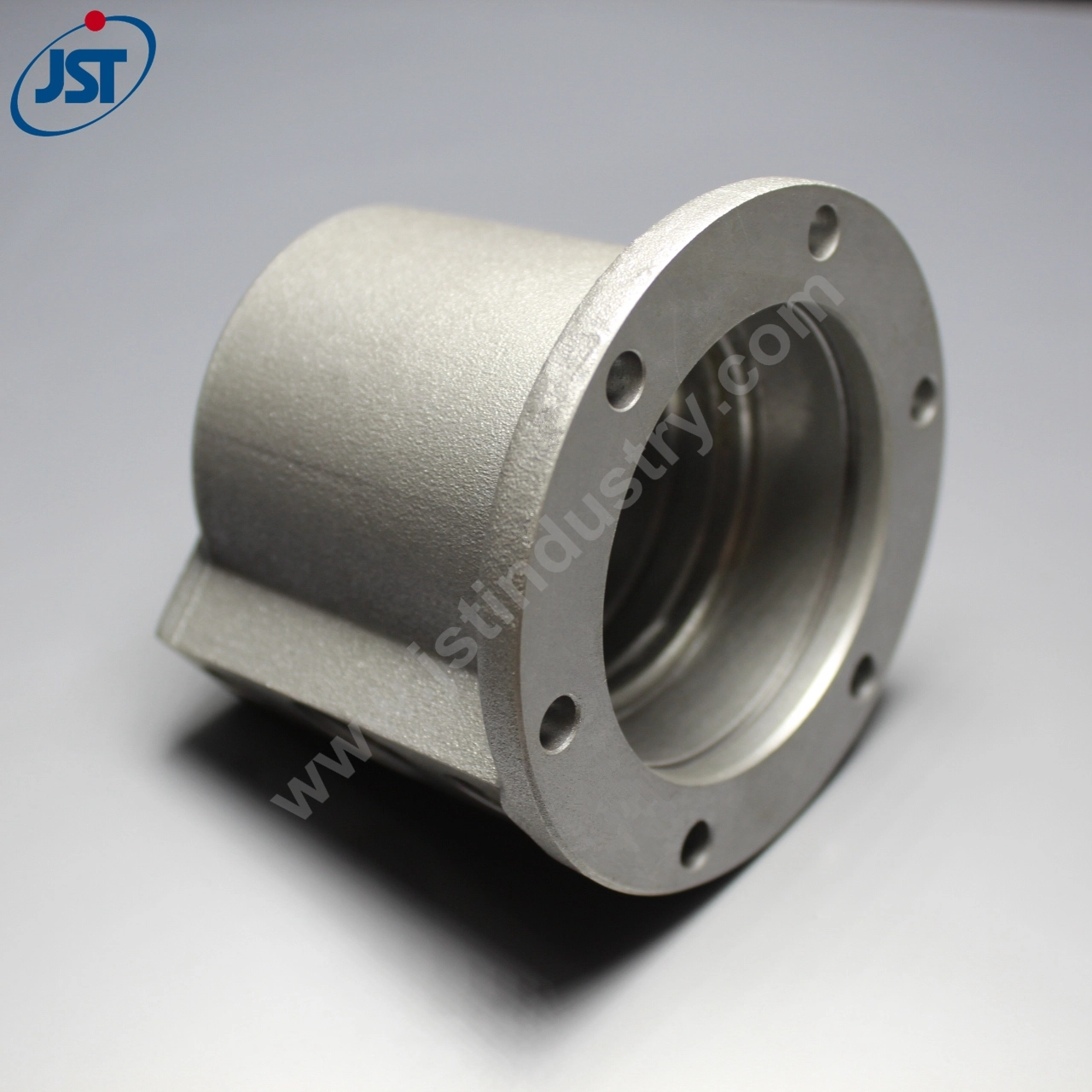

JST’s gravity industrial aluminum sand casting is a rotor component specially designed for the automotive industry, made of high-quality aluminum alloy materials. Through the advanced gravity casting process, we can ensure the high strength and good durability of the gravity industrial aluminum sand casting. Our products are shot peened with a good surface finish, which can effectively meet the high standards of the automotive industry. As an OEM manufacturer of gravity industrial aluminum sand castings, JST also provides additional processing and finishing to ensure the excellent performance of the products in the application.

Product Features:

1. High-quality aluminum alloy materials: We use high-standard aluminum alloy materials to ensure that the gravity industrial aluminum sand castings have excellent strength, lightweight characteristics, and corrosion resistance, suitable for long-term use in harsh environments.

2. Accurate casting process: Using the gravity casting process, we are able to produce gravity industrial aluminum sand castings with complex shapes and accurate dimensions. The general tolerance of aluminum sand castings is CT-6, ensuring a perfect fit during assembly and installation.

3. Surface treatment optimization: Shot peening is used to further improve the surface quality of gravity industrial aluminum sand castings, reduce the surface roughness to Ra 6.3, and enhance the wear resistance and aesthetics of the product.

4. Custom processing services: In addition to gravity industrial aluminum sand castings, we also provide additional processing and finishing solutions that can be adjusted according to the specific needs of customers to ensure that each part can achieve the best performance standards.

5. Robust delivery time: We can provide a minimum order of 1,000 pieces according to customer needs, with a delivery time of 45 days, ensuring that customers receive timely supply and service.

Product Value:

– Efficient production capacity: Our production process is optimized to produce a large number of gravity industrial aluminum sand castings at an efficient speed and high-quality standards, meeting customers’ dual requirements for quantity and quality.

– Cost-effectiveness: The production cost of gravity industrial aluminum sand castings is relatively low, which enables our products to maintain a good economy while providing high performance and reliability, helping customers reduce production costs.

– Strong adaptability: Our various gravity industrial aluminum sand castings can be applied to a wide range of different automotive areas, making sure they will meet the ever-changing needs of the market and provide flexible solutions to customers.

– Quality assurance: We guarantee that every gravity industrial aluminum sand casting has been strictly inspected for quality to meet international and industry standards, so as to ensure that customers can use it without any worry.

Application Scope:

The main fields of application of JST’s gravity industrial aluminum sand castings are in the following fields:

– Automotive industry: It is used in engine components, transmission systems, and suspension systems to improve the overall performance and efficiency of the vehicle.

– Aerospace: In some spacecraft and related equipment, the lightweight and corrosion-resistant properties of aluminum alloys are widely used.

– Mechanical equipment: Gravity industrial aluminum sand castings also play an important role in the structural parts, casings, and other parts requiring strength and light weight of various mechanical equipment.

– Home appliance industry: Gravity industrial aluminum sand castings are also used in some high-end home appliances to improve their aesthetics and durability.

——

JST’s gravity industrial aluminum sand casting uses high-standard aluminum alloy materials to ensure that the castings have excellent strength, lightweight characteristics, and corrosion resistance, suitable for long-term use in harsh environments. Please feel free to contact us for more information or a quote.

1. How long is the delivery time for gravity industrial aluminum sand castings?

Our standard delivery time is 45 days, but we will try our best to meet customers’ special requirements.

2. Can customized production be made?

Of course, we are committed to providing customized services according to our customers’ specific needs, including design and size.

3. What is the minimum order quantity for the gravity industrial aluminum sand casting?

Our minimum order quantity is 1,000 pieces to ensure efficient and economical production.

4. What is the guarantee about the quality of the gravity industrial aluminum sand casting?

All castings are subjected to strict quality inspections to ensure that the products meet the requirements of the industry.

5. Additional processing for the already manufactured gravity industrial aluminum sand castings?

Yes, we can do more processes and finish after casting to ensure the products will meet the specific requirements of the customers.

“The gravity industrial aluminum sand castings provided by JST were beyond expectation, and very reliable in both quality and delivery time. The service team is also professional, which makes the cooperation process quite smooth and enjoyable.” – Mr. Wang, an automotive manufacturer.

“As a quality-oriented company, JST is the best casting supplier for us. Their products are excellent in performance and greatly helpful for our business development.” – Mr. Li, machinery and equipment manufacturer.