Customized Precision CNC Milling Aluminum Parts XL

Customized Precision CNC Milling Aluminum Parts XL Collection

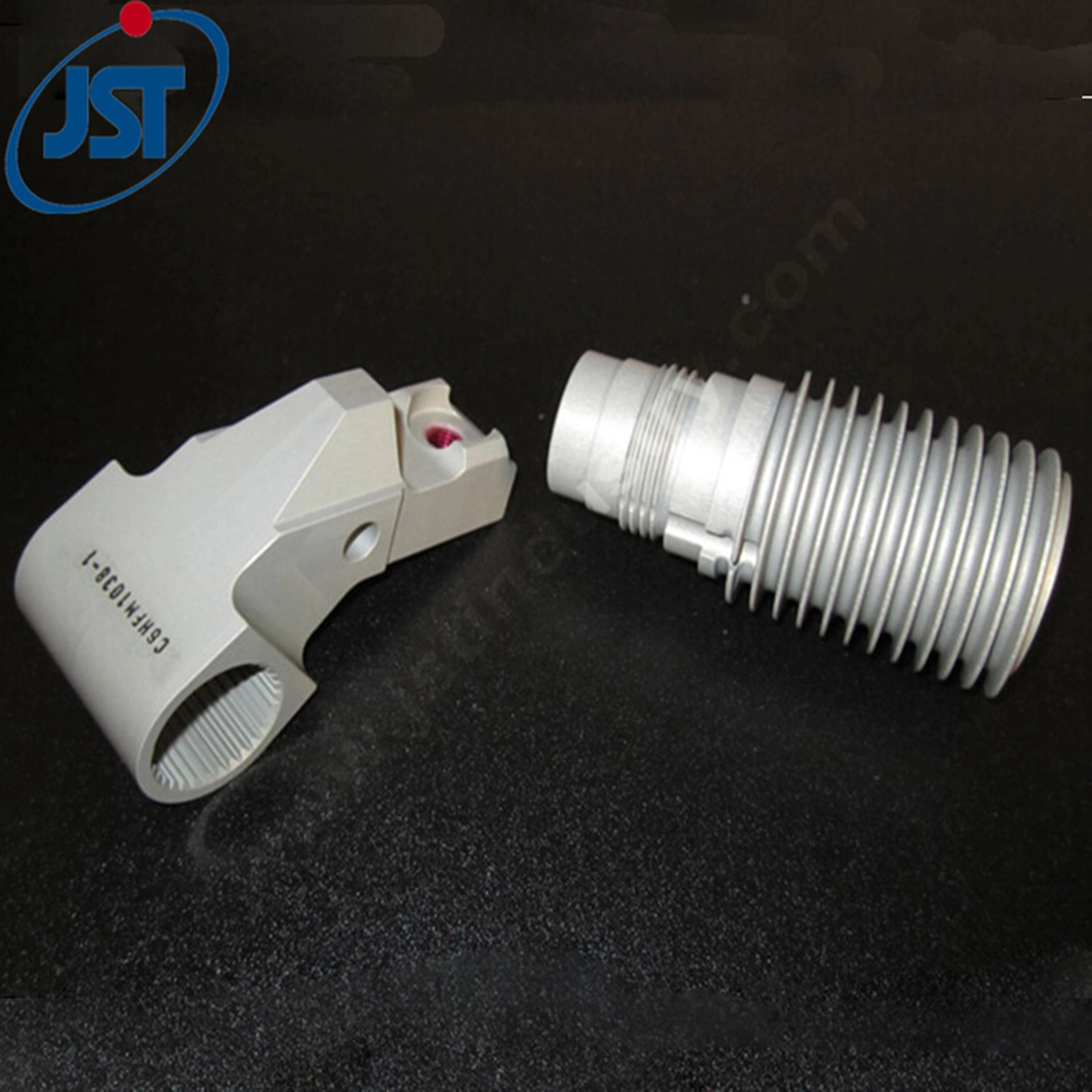

JST’s customized precision CNC milling aluminum part XL is designed for the industrial robotics field. It uses high-performance AL7075-T6 aluminum alloy material with excellent strength and corrosion resistance. Our customized precision CNC milling aluminum parts XL are strictly processed to ensure that the tolerance is controlled within ±0.01 mm, meeting the high precision requirements of the industry. The sandblasted and transparent anodized surface not only improves the wear resistance of the parts but also gives them an elegant appearance. Our main customers include well-known brands such as Midea and Gree, and with rich experience, our products have performed well in the market.

Product Features:

1. High strength and lightweight: The AL7075-T6 aluminum alloy is a protruding sculptor of stiffness and strength and makes the final products light and strong enough to meet high-load applications.

2. Precision machining: Our CNC milling process guarantees that each customized precision CNC milling aluminum part XL has a dimensional accuracy of about ±0.01 mm, meeting the highly sensitive accuracy standards required for robots and automation equipment.

3. High surface quality treatment: Sanded and clear-anodized surfaces are not only beautiful but also highly resistant to corrosion and wear providing superior quality and longer lifetimes for components.

4. Tight screw fits: Attention is paid to design details where threads are concerned, assuring stability and safety of the customized precision CNC milling aluminum parts XL as they are assembled, enhancing the overall performance.

5. Flexible customization possibilities: Small- or large-scale productions can be intelligently met through rapid response measures taken whenever customers need customized solutions addressed to suit different application scenarios.

Product Value:

Choose the customized precision CNC milling aluminum parts XL by JST, and you will find out that they add several values:

– Improving production efficiency: High-precision customized precision CNC milling aluminum parts XL can significantly boost the efficiency of the entire production process and minimize rework or waste due to overall misfit.

– Enhance competitive advantage: With the promotion of 5G and smart manufacturing, automated production is becoming more and more popular. Supplying high-quality and customized precision CNC milling aluminum parts XL will promote customers’ competitiveness in the market.

– Cost-effectiveness: Optimized production processes and material usage can reduce the production cost of each customized precision CNC milling aluminum part XL while maintaining high-quality standards and improving cost-effectiveness.

– Rapid market response capability: Our production and delivery capabilities ensure that customer products can be quickly launched, seize market opportunities, and meet customers’ rapidly changing needs.

Application Scope:

JST’s customized precision CNC milling aluminum parts XL are widely used in various industrial robotics fields and other industries with high precision operation requirements.

– Robot arms and automation equipment: Serve as joints or connectors in industrial robots to ensure efficient operation of mechanical equipment.

– Aerospace: The high-strength but lightweight characteristics make these parts meet the strict material requirements of the aviation industry.

– Medical equipment: Used in high-standard applications in precision medical devices, which must meet strict hygiene and food safety standards.

– Electronic products: Used in accessories for mobile phones and other smart devices to meet the needs of precision assembly and functional performance.

——

JST’s customized precision CNC milling aluminum partsXL has a sandblasted and transparent anodized surface, which not only has a good appearance but also has excellent corrosion resistance and wear resistance, extending the service life of the parts. If you would like to learn more about our products or get a quote, please feel free to contact us!

1. What is the minimum order quantity?

The minimum order quantity for our customized precision CNC milling aluminum parts XL is 2,500 pieces.

2. How long is the delivery cycle?

The standard delivery time is 30 days, and the specific time can be negotiated separately depending on the size and complexity of the order.

3. How to customize the product?

We welcome customers to provide part design drawings, and our team will provide you with comprehensive services including design, manufacturing, and processing.

4. What are the surface treatment options?

Our standard surface treatment is sandblasting and transparent anodizing. In addition, we can also provide other treatment solutions according to customer needs.

5. How to get a quote?

Please send the design drawings and relevant information to our official email address, and we will submit a quote for you as soon as possible.

“JST’s customized precision CNC milling aluminum parts XL are of high quality and stable precision, which greatly improve the overall efficiency of our industrial robot project.” – Midea Technology Group Engineer.

“From design to production, JST has shown excellent professionalism, which makes us confident in the launch of new products.” – Gree Electric Project Manager.

“Our cooperation with JST is smooth. Their customization capabilities and response speed make our production more flexible and reliable.” – Automation Equipment Manufacturer.