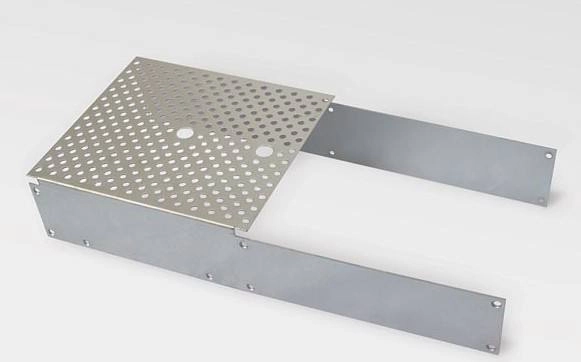

Custom Industrial Stainless Steel Sheet Metal Fabrication

Custom Industrial Stainless Steel Sheet Metal Fabrication Collection

Welcome to JST’s custom industrial stainless steel sheet metal fabrication services. Our professional sheet metal processing solutions will transform your project, combining precision craftsmanship with cutting-edge manufacturing technology to make your work stand out. We are committed to meeting the needs of different industries and providing high-end stainless steel parts that are both functional and aesthetic. We use high-quality materials and excellent craftsmanship to ensure that each product perfectly meets your specifications.

Product Features:

1. Excellent Sheet Metal Processing Technology

Our process of treating sheet metals is incomparable. Each product is strictly reviewed so that every detail is perfectly polished and meets the high-quality set during production. Our team’s rich experience in the industry allows us to understand and meet the unique needs of customers in different fields.

2. High-Quality Stainless Steel Alloy

The stainless steel alloys used are strictly screened for excellence in strength and corrosion resistance. Whether it is the ability to resist oxidation or bear bad environments, our stainless steel sheet metal fabrication can maintain efficient performance. Meanwhile, elegant surface treatment adds to its aesthetic look and achieves a perfect balance between practicality and beauty.

3. Advanced Manufacturing Technology

With a combination of state-of-the-art manufacturing equipment and technology, we redefine the possibilities of stainless steel sheet metal fabrication. High-precision cutting, punching, and bending processes make complex designs and tight tolerances part of everyday operations, further demonstrating our commitment to excellence.

4. Better Performance

Our stainless steel sheet metal fabrication product greatly helps in improving your project performance, functionality, and reliability. Not only are these parts highly adaptable, but they also effectively meet the requirements of any project, increasing work efficiency while improving overall structural and mechanical performance.

5. Quality Assurance

Every plate treated in our facility undergoes strict quality assurance. We are committed to outperforming benchmarks and setting new standards for the durability and precision of every stainless steel sheet metal fabrication, enabling customers to feel safe and assured at every juncture.

6. Industry Diversification

Our stainless steel sheet metal fabrication solutions can be applied to a wide range of industries, from construction, transportation, and manufacturing to medical and electronics. In each of these different projects, our products can be adapted to meet unique needs, thus offering customers true versatility.

7. Unlimited Design Freedom

In design, we are offering endless possibilities. Whether an attractive look, complex dimensions, or functional customization requirements, our professional team can do it for you with the help of stainless steel sheet metal fabrication technology in stainless steel.

8. Economically Efficient Precision Control

Our solutions for stainless steel sheet metal fabrication are excellent not only in precision but also in cost-effectiveness. You will be able to enjoy high precision without any apprehension about high production costs. The optimized process will maximize production efficiency.

9. Aesthetic Brilliance

We care about not only the performance but also the look. Manufacturing stainless steel sheet metal fabrication could greatly improve the look of the project. Seamless integration of design makes the function and appearance perfectly unified, and impressive.

Product Value:

1. Improved durability: The superior durability of our stainless steel sheet metal fabrication products with respect to superior physical and chemical properties makes them suitable for a wide range of application scenarios and environments, hence reducing maintenance costs while prolonging the service life.

2. Efficiently improve the performance of the project: High-quality sheet metal processing is able not only to improve the functionality of the stainless steel sheet metal fabrication itself but also brings significant efficiency improvements in customers’ projects, so they run smoothly in many applications.

3. Support environmental protection: With long-lasting and durable designs for stainless steel sheet metal fabrications our manufacturing process effectively reduces resource waste. In the use of recyclable stainless steel materials, we ensure that our production process meets the requirements for sustainable development.

4. Long-term reduction of operating costs: The excellent performance and durability of stainless steel sheet metal fabrications mean customers do not have to replace or conduct frequent maintenance; to some extent, this cuts long-term operating costs and enhances return on investment.

Range of Application:

Our custom industrial stainless steel sheet metal fabrication products find broad applications in a variety of industries, including but not limited to:

– Construction industry: Used for water supply pipes, building structural parts, etc., to make them strong and resistant to corrosion.

– Automobile manufacturing: Used for accessories and body structure to enhance the safety and durability of automobiles.

– Electronic manufacturing: Used for housings, brackets, cooling systems, etc., to enhance the appearance of design while making sure that the performance can be ensured.

– Medical devices: Used for medical devices and accessories with high hygiene standards, ensuring safety and effectiveness.

– Food processing: Manufacture equipment and storage containers using food-safe stainless steel materials.

——

JST’s custom industrial stainless steel sheet metal fabrication is suitable for various environments and application scenarios, effectively reducing maintenance costs and extending service life. Welcome to contact us for more product details.

1. What is the process of customized service?

Our customization usually includes an initial consultation, confirmation of design, arrangement for production, and quality inspection. We only need customers to provide relevant design drawings or specifications, and we will assist you in completing the whole process.

2. How long is the production cycle?

The production cycle is different according to the complexity and quantity of a particular project. Normally, we take 1 to 6 weeks for completion of production. A detailed delivery time will be given after we confirm the order.

3. Do you have an MOQ?

Our company supports flexible customization services. The minimum order quantity is generally product type and customer requirements based. Welcome to negotiate details with us.

4. How to guarantee the quality of the custom industrial stainless steel sheet metal fabrication?

By strictly and rigorously carrying out the production process, quality control systems are guaranteed to ensure every piece of custom industrial stainless steel sheet metal fabrication has been inspected multiple times to meet the promised quality.

5. Can samples be provided?

Normally, samples can be provided according to customer requirements for further confirmation of design and quality requirements.

Our customers highly praise the service of custom industrial stainless steel sheet metal fabrication. Here are some real customer feedbacks:

1. Construction company: “The sheet metal processing service of JST helps us to achieve unexpected precision for complex projects, and the durability of the product will improve the quality of our projects.”

2. Automobile manufacturer: “We have been looking for a reliable supplier. JST’s custom industrial stainless steel sheet metal fabrication quality exceeded expectations. Its stainless steel parts not only enhance the reliability of the product but also have excellent visual effects.”

3. Medical device company: “In the medical industry, precision and hygiene standards are particularly important. JST met all our requirements and made our custom industrial stainless steel sheet metal fabrications safer, thus winning the trust of customers.”

4. Electronic product manufacturer: “We are pleasantly surprised by JST’s design freedom. The final product is not only powerful but also very beautiful, which perfectly matches our product positioning.”